Patterned substrate and preparation method thereof

A graphics substrate and graphics technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., to achieve the effect of improving light extraction efficiency and reducing multiple reflections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

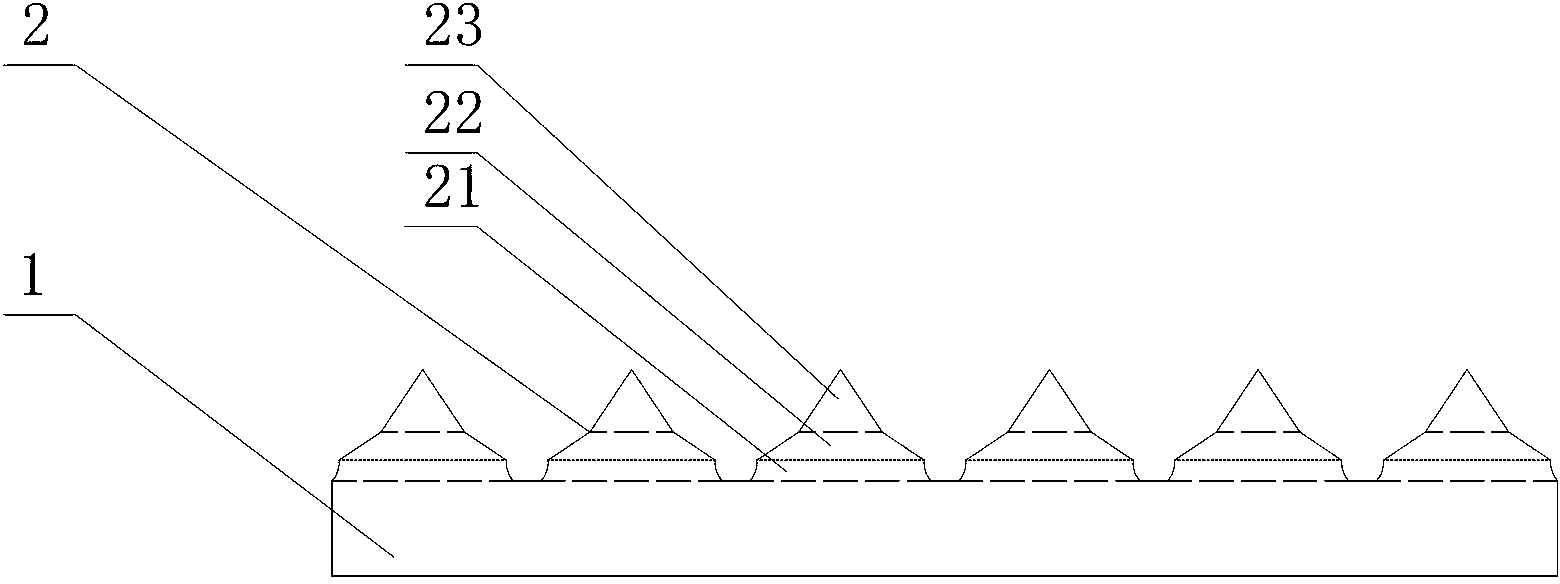

[0034] Embodiment 1: the preparation method of described figure substrate, adopt following process step:

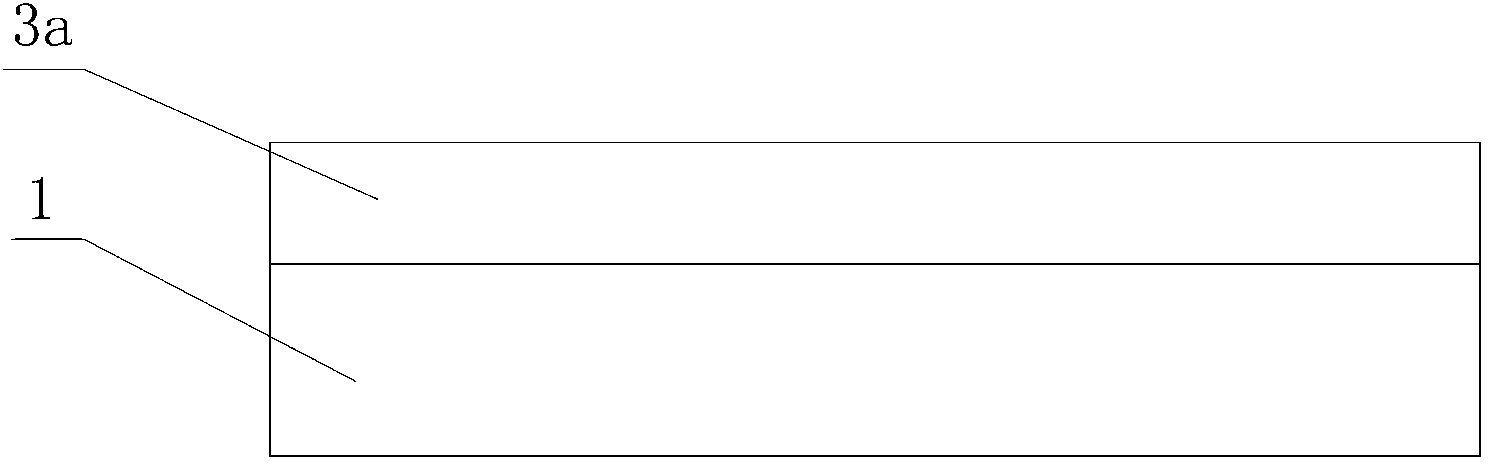

[0035] (1) Provide a basic substrate 1 with a front side and a back side, and the basic substrate 1 is a sapphire substrate; for example image 3 As shown, a layer of heterogeneous substrate 3a is formed on the upper surface of the basic substrate 1 to obtain a composite substrate. The thickness of the heterogeneous substrate 3a is 0.5 μm, and the material of the heterogeneous substrate 3a is SiO 2 、Si 3 N 4 , ZnO 2 , Si or GaAs;

[0036] (2) Clean the composite substrate;

[0037] (3) if Figure 4 As shown, a photoresist 4a is coated on the surface of the conductive substrate 3a of the composite substrate, and the thickness of the coating is 0.5 μm, and the exposure and development are carried out to expose the area to be etched;

[0038] (4) Dry etching and wet etching are used to etch once respectively, the total etching depth is 1 μm, and pattern protrusions 2 a...

Embodiment 2

[0040] Embodiment 2: The preparation method of described graphics substrate adopts the following process steps:

[0041] (1) Provide a basic substrate 1 with a front side and a back side, and the basic substrate 1 is a silicon carbide substrate; for example image 3 As shown, a layer of heterogeneous substrate 3a is formed on the upper surface of the basic substrate 1 to obtain a composite substrate. The thickness of the heterogeneous substrate 3a is 2 μm, and the material of the heterogeneous substrate 3a is SiO 2 、Si 3 N 4 , ZnO 2 , Si or GaAs;

[0042] (2) Clean the composite substrate;

[0043] (3) if Figure 4 As shown, a photoresist 4a is coated on the surface of the conductive substrate 3a of the composite substrate, and the thickness of the coating is 4 μm, and the exposure and development are carried out to expose the area to be etched;

[0044] (4) Dry etching and wet etching are used to etch once respectively, the total etching depth is 4 μm, and pattern protrus...

Embodiment 3

[0046] Embodiment three: the preparation method of described graphics substrate adopts the following process steps:

[0047] (1) Provide a basic substrate 1 with a front side and a back side, where the basic substrate 1 is a sapphire substrate, a silicon carbide substrate or a silicon substrate;

[0048] (2) Coating photoresist 4a on the surface of the basic substrate with a coating thickness of 1 μm, exposing and developing to expose the area to be etched;

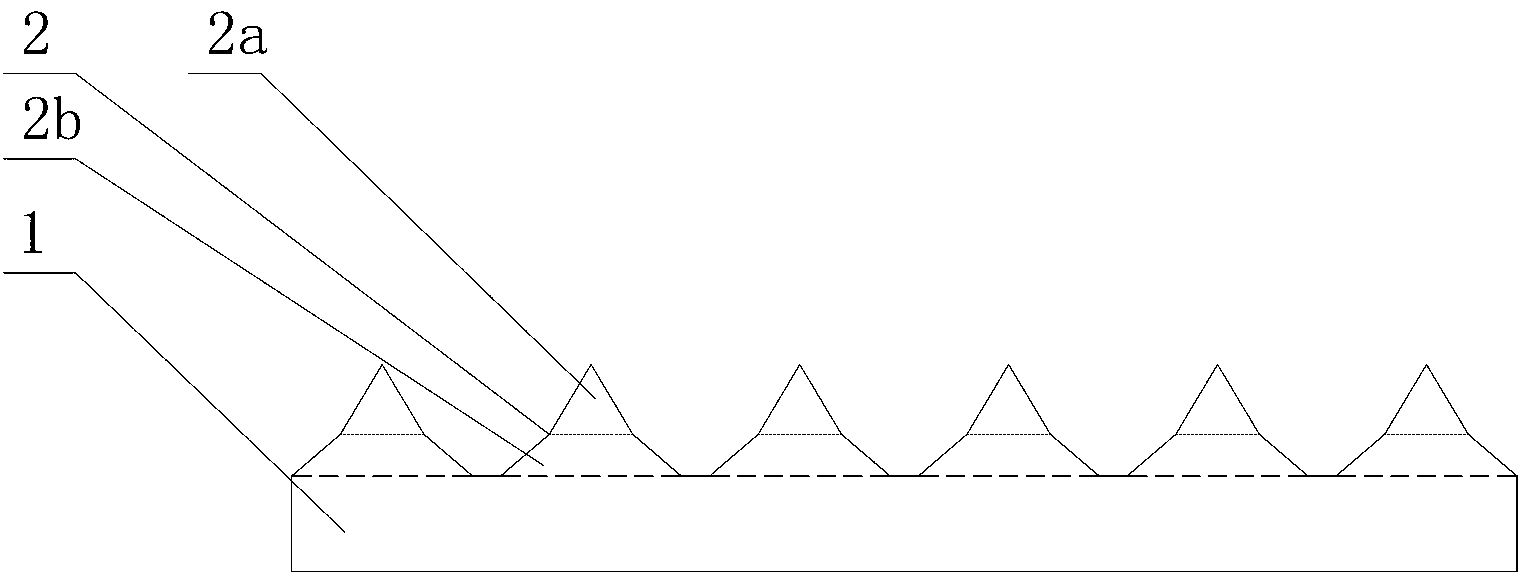

[0049] (3) Dry etching and wet etching are used to etch once respectively, the total etching depth is 1 μm, and pattern protrusions 2 are obtained by etching on the front side of the basic substrate 1, such as figure 1 As shown, the pattern protrusions 2 are arranged in an array on the front of the basic substrate 1, and the pattern protrusions 2 are composed of upper layer protrusions 2a and lower layer protrusions 2b, the bottom width of the upper layer protrusions 2a is the same as the top width of the lower layer pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com