Photobioreactor system

A photobioreactor, photosynthetic biology technology, applied in photobioreactor, bioreactor/fermenter combination, bioreactor/fermenter for specific purposes, etc., can solve the problems of death, low yield, long light path, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

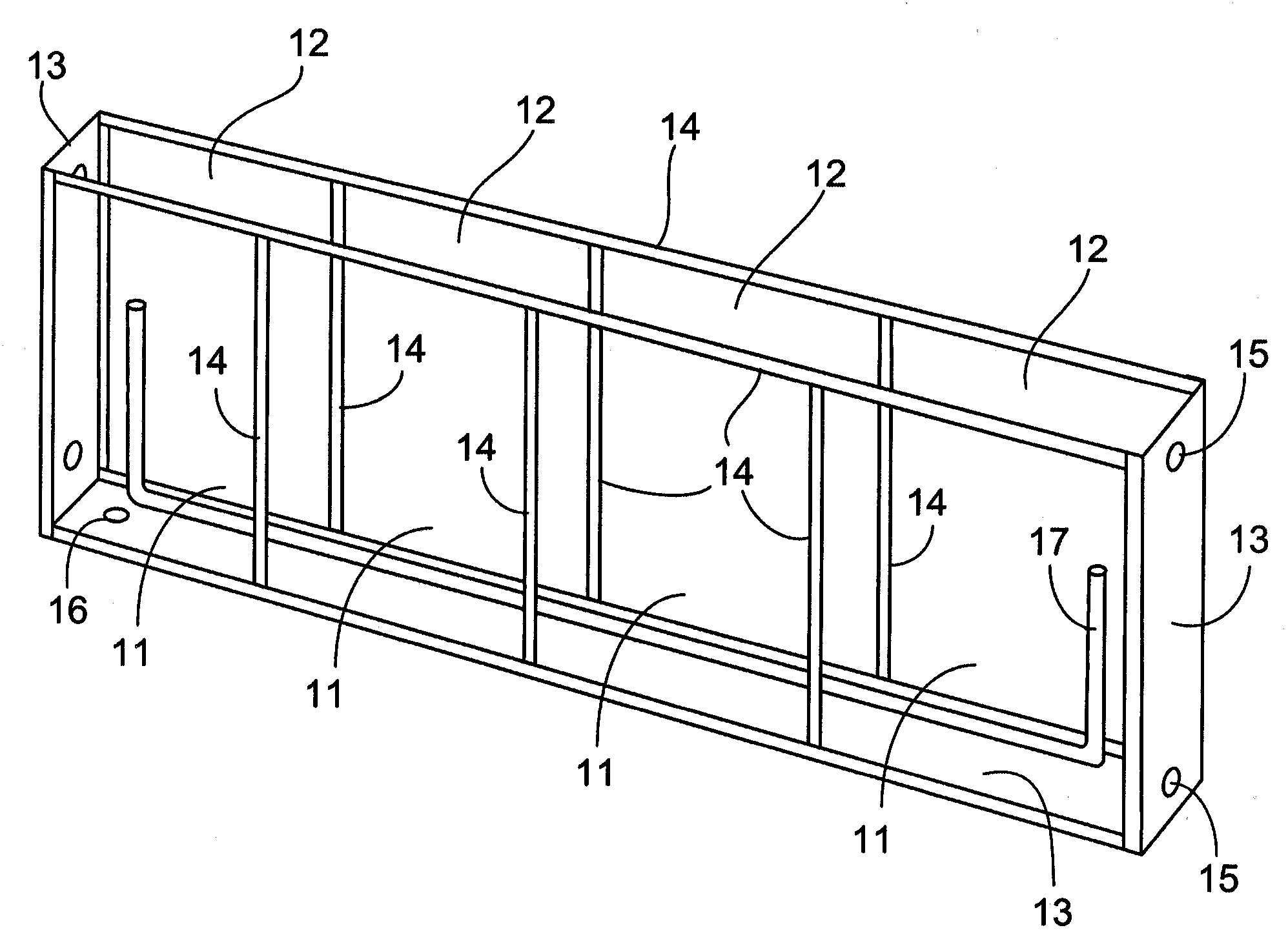

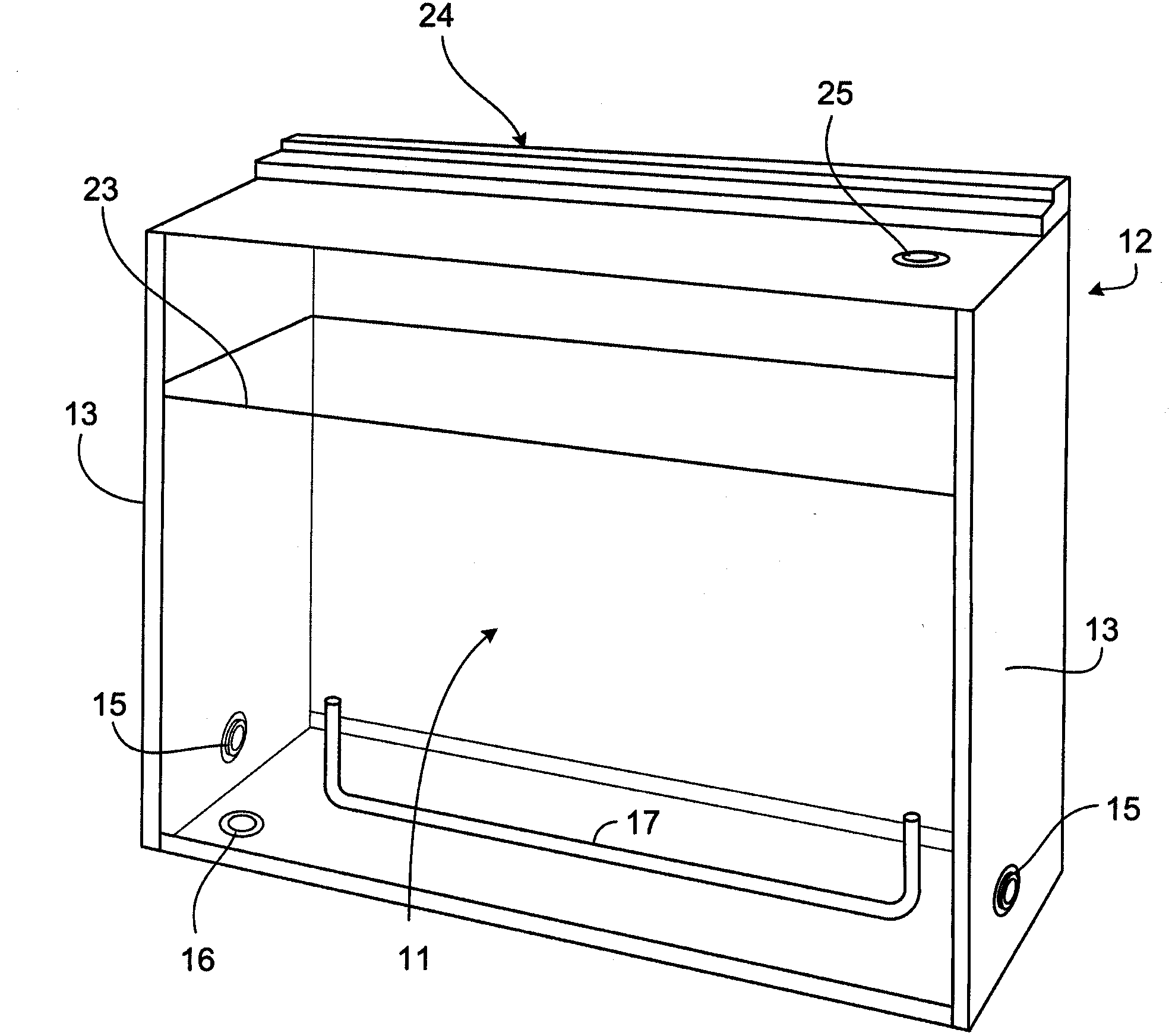

[0011] [11] Compared with the prior art, the current invention provides a new design of photobioreactor using U-shaped frame, which has stronger configuration, flexible size, convenient construction and operation, and enables multiple A cascade of bioreactors is possible.

[0012] [12] The U-shaped frame is usually made of stainless steel (or other supporting material) to make the photobioreactor more robust; the size of the photobioreactor can have a wider range (using a U-shaped configuration makes very thin or very long reactor units possible);

[0013] [13] Such devices are easier to build by simply adding glass or other transparent materials to the sides; they also make it easier to harvest cultured algae, wash and clean the photobioreactor.

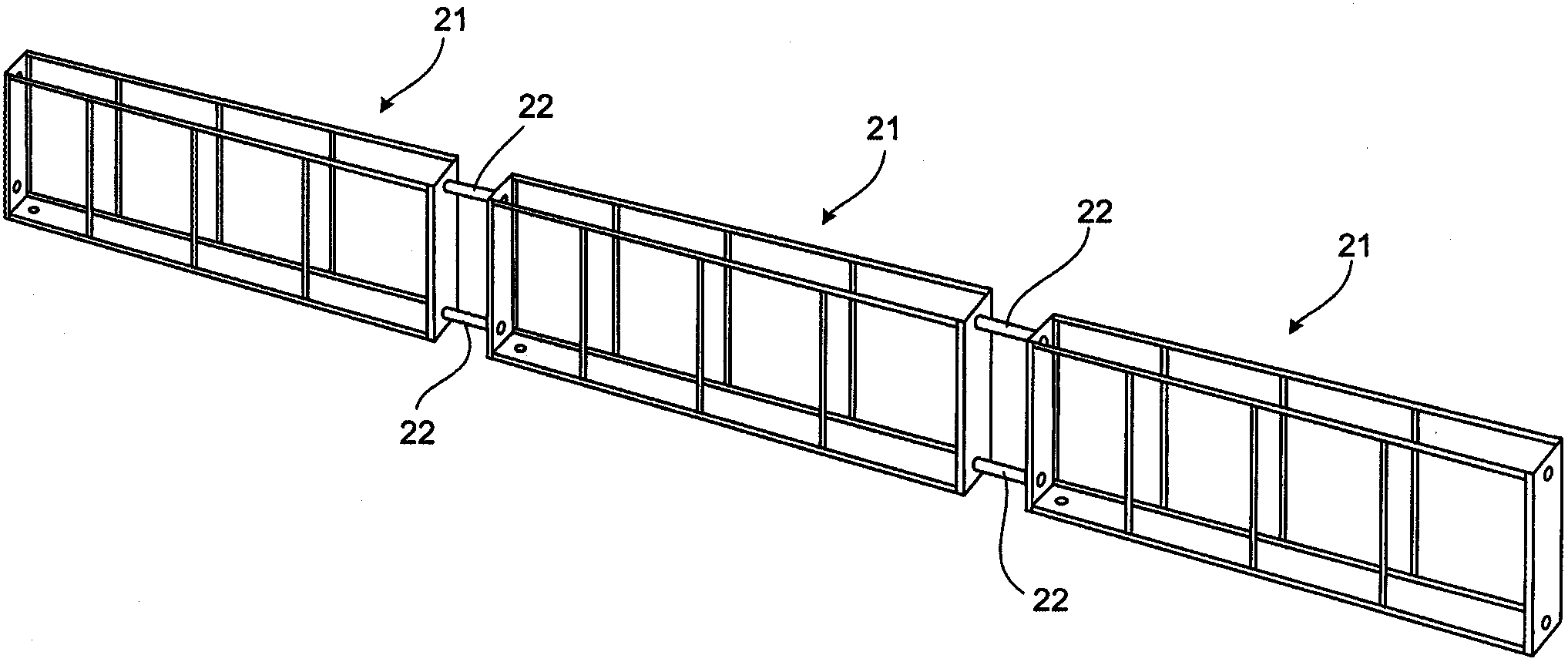

[0014] [14] The interconnectivity of each photobioreactor unit makes it possible to construct a cascade of many individual photobioreactor units, and the operating efficiency can be greatly improved.

[0015] [15] The design, fabr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com