Fluorine-based polymer thin film and method for preparing same

A technology for polymer films and substrates, used in bonding methods, chemical instruments and methods, ester copolymer adhesives, etc., can solve problems such as poor bonding strength, achieve easy repair, maintain water resistance and antifouling properties , the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

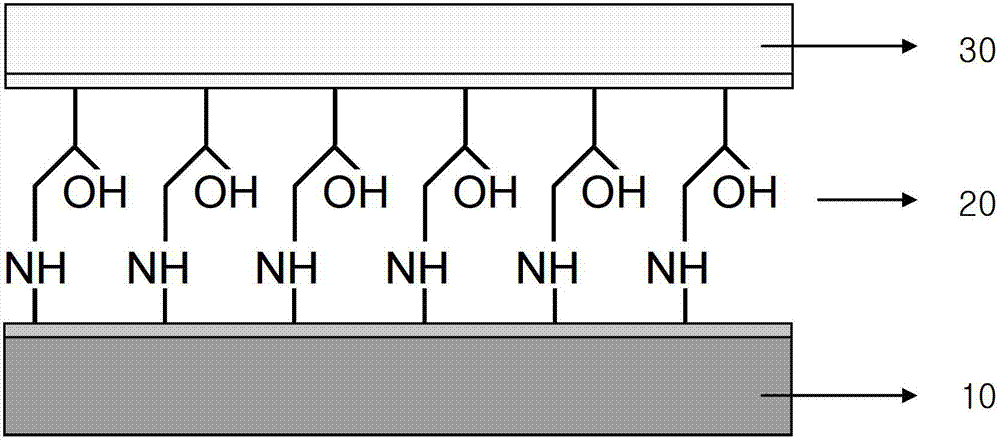

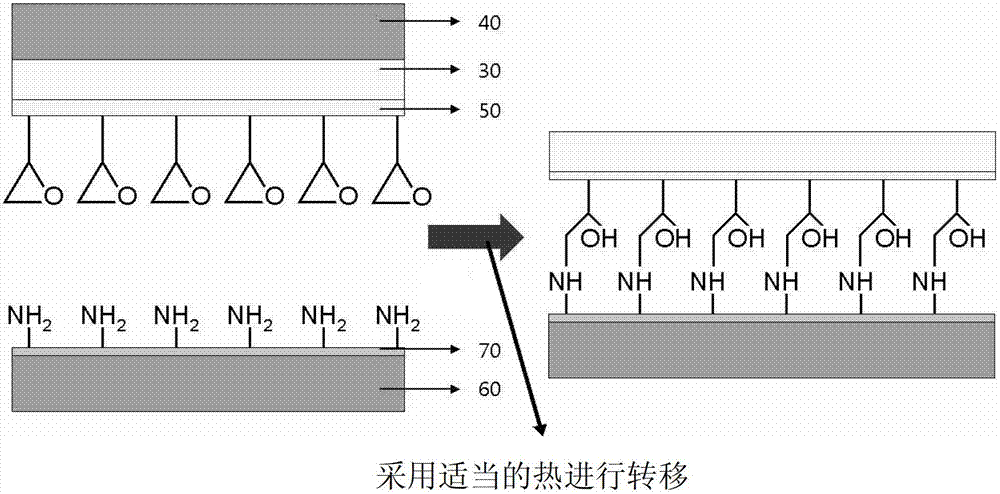

[0028] The method for preparing a fluorine-based polymer film according to the present invention includes the following steps: a) forming a fluorine-based polymer film on a first substrate; b) forming a fluorine-based polymer film containing a first functional group on the fluorine-based polymer film. a thin layer; c) forming a thin layer comprising a second functional group on a second substrate; and d) chemically bonding the first functional group and the second functional group to each other.

[0029] The method for preparing a fluorine-based polymer thin film according to the present invention may further include separating the first substrate after step d).

[0030] Step a) is a step of forming a fluorine-based polymer film on a first substrate, the fluorine-based polymer film can be formed using a method known in the art, more specifically, the fluorine-based polymer The thin film can be formed using sputtering method, reduced pressure CVD method, plasma CVD method, hot ...

Embodiment 1

[0058] 1) A thin layer of PTFE is deposited using the HWCVD method. In this case, the monomer source used was gaseous HFPO (hexafluoropropylene oxide). The deposited PTFE thin layer has a thickness of 100 nm or less.

[0059] 2) After increasing the wettability by oxygen plasma treatment of the samples prepared in 1), polyglycidyl methacrylate was deposited using the HWCVD method. In this case, the deposited PGMA has a thickness of about 100 to 200 nm.

[0060] 3) The substrate prepared in 2) and the aminosilane-treated glass were thermally cured in an oven at 150° C. for 1 to 3 hours under normal pressure by applying a predetermined pressure.

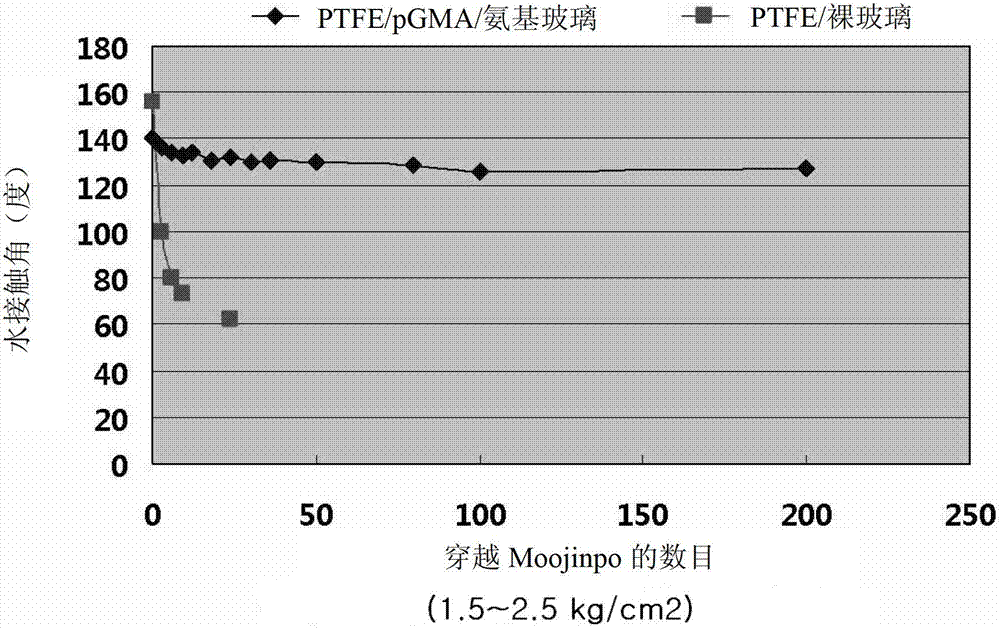

[0061] 4) The results in Table 1 below were obtained by measuring the water contact angle and surface energy of the sample transferred in 3).

[0062] 5) The adhesive properties of the sample on which PTFE was transferred and the PTFE on which bare glass was placed were confirmed by the change of water contact angle with the number ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com