Screening-free stirring tank body and dedicated soil dressing spray-seeding machine

A mixing tank and guest soil spraying technology, which is applied in the direction of sowing seeders, fertilizers and seeding equipment, etc., can solve the problems of increasing construction costs, reducing construction efficiency, damaging pump casings or impellers, etc., so as to save construction costs and improve construction efficiency , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

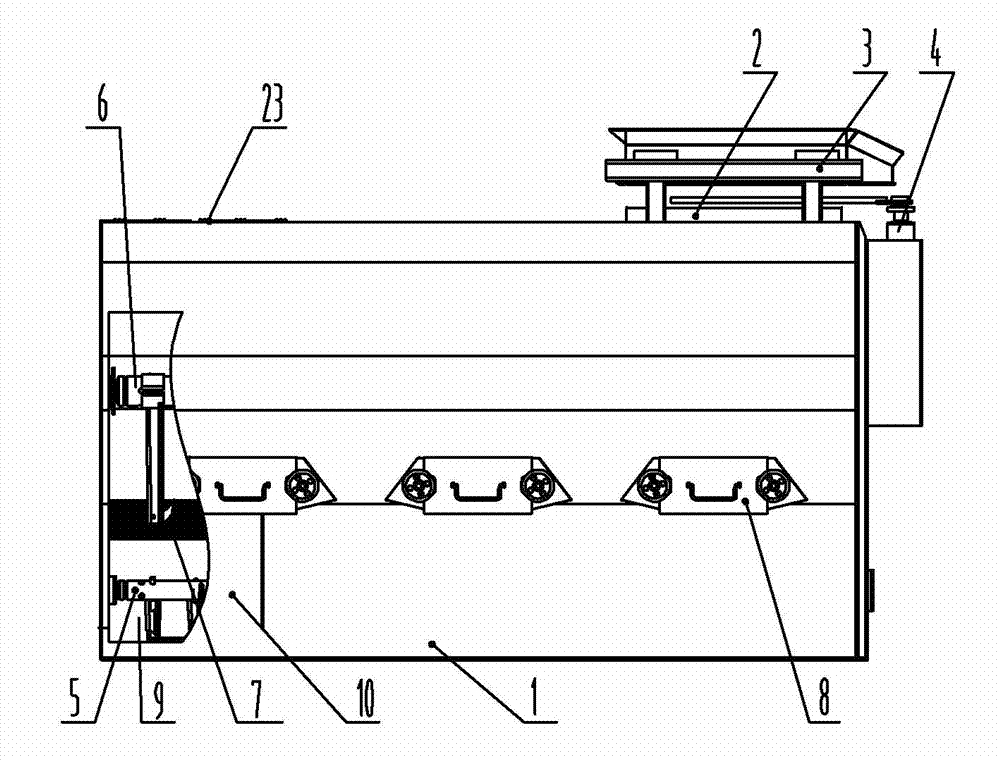

Image

Examples

Embodiment 1

[0033] Embodiment two:

Embodiment 2

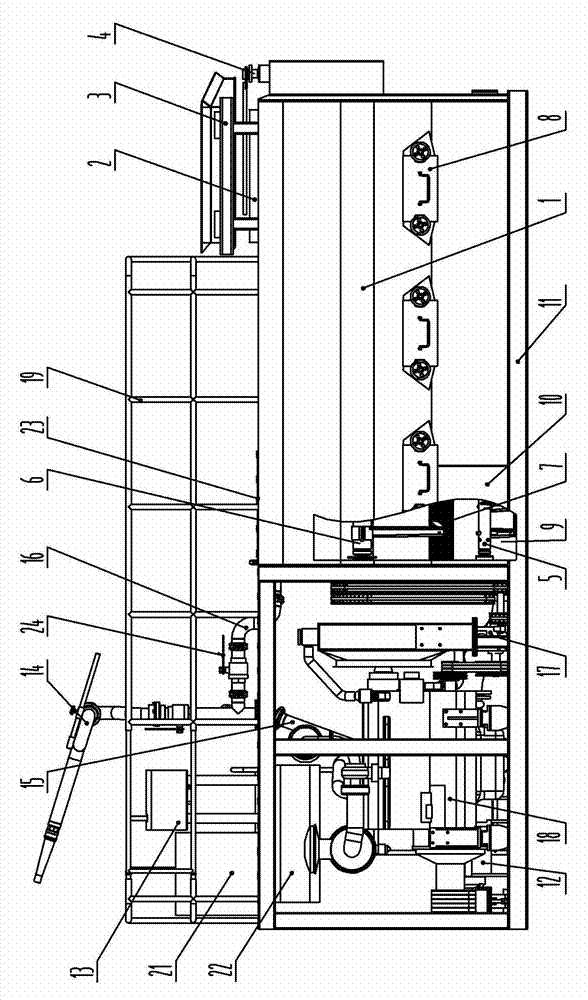

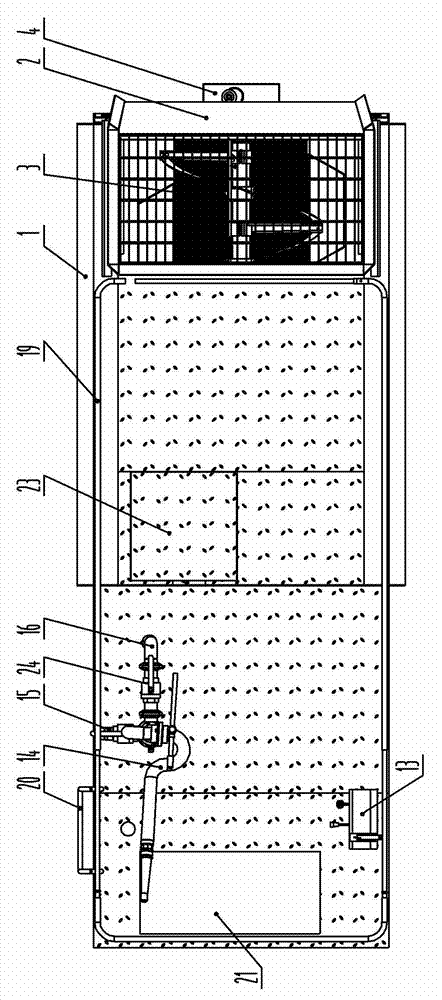

[0035] Described power mechanism is two diesel engines 18. The transmission mechanism is composed of a first transmission mechanism and a second transmission mechanism. The first transmission mechanism is a belt transmission mechanism connected with the thick slurry pump, and the second transmission mechanism is a chain transmission mechanism connected with the stirring system. Valves 24 are installed on the conveying pipeline system and the return pipeline system. The spraying rack gun 14 is a universal sprinkler rack gun. The frame top is provided with a guardrail 19 on three sides, one side is open, and a ladder 20 leading to the top of the frame is provided on the open side. A toolbox 21 is installed on the top of the frame and one side of the console, an oil tank 22 is installed on the frame above the mud pump, and an observation window 23 is provided on the top of the mixing tank.

[0036] Working process of the present invention is as follows:

[0037] When working, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Mesh diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com