Preparation process of Zhejiang fritillaria ultrafine powder

A preparation process, the technology of Fritillaria fritillaria, is applied in the field of preparation technology of Fritillaria fritillaria superfine powder, which can solve the problem of insufficient retention of active ingredients in Fritillaria fritillaria superfine powder, and achieve the effect of rapid water absorption recovery, same quality and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

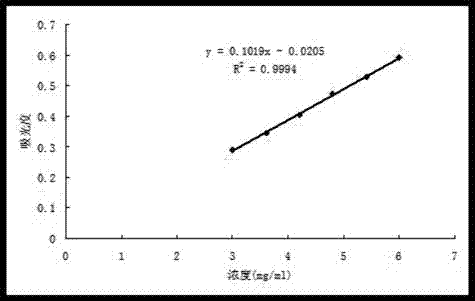

Image

Examples

Embodiment 1

[0030] A preparation process of Fritillaria superfine powder, comprising the following steps:

[0031] ①Material selection: Fritillaria fritillaria;

[0032] ② Grinding and beating: Grinding after adding distilled water, the amount of distilled water added is 0.8 times the quality of Fritillaria raw material;

[0033] ③Pre-freezing: The standard for pre-freezing is to freeze into a solid state, and maintain the frozen solid state for 5 hours;

[0034] ④ Freeze-drying: the control condition of freeze-drying is -45°C for 24 hours;

[0035] ⑤Powdering: The operation of grinding into micropowder is carried out by using a vibrating ultrafine pulverizer, grinding and kneading machine.

Embodiment 2

[0037] A preparation process of Fritillaria superfine powder, comprising the following steps:

[0038] ①Material selection: Fritillaria fritillaria;

[0039] ② Grinding and beating: Grinding after adding distilled water, the amount of distilled water added is 0.85 times the quality of Fritillaria fritillata raw material;

[0040] ③ Pre-freezing: The standard for pre-freezing is to freeze into a solid state, and maintain the frozen solid state for 5.5 hours;

[0041] ④ Freeze-drying: the control condition of freeze-drying is -45.5°C for 28 hours;

[0042] ⑤Powdering: The operation of grinding into micropowder is carried out by using a vibrating ultrafine pulverizer, grinding and kneading machine.

Embodiment 3

[0044] A preparation process of Fritillaria superfine powder, comprising the following steps:

[0045] ①Material selection: Fritillaria fritillaria;

[0046] ② Grinding and beating: Grinding after adding distilled water, the amount of distilled water added is 0.90 times the quality of Fritillaria raw material;

[0047] ③ Pre-freezing: The standard for pre-freezing is to freeze into a solid state, and maintain the frozen solid state for 6 hours;

[0048] ④ Freeze-drying: the control condition of freeze-drying is -46°C for 32 hours;

[0049] ⑤Powdering: The operation of grinding into micropowder is carried out by using a vibrating ultrafine pulverizer, grinding and kneading machine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com