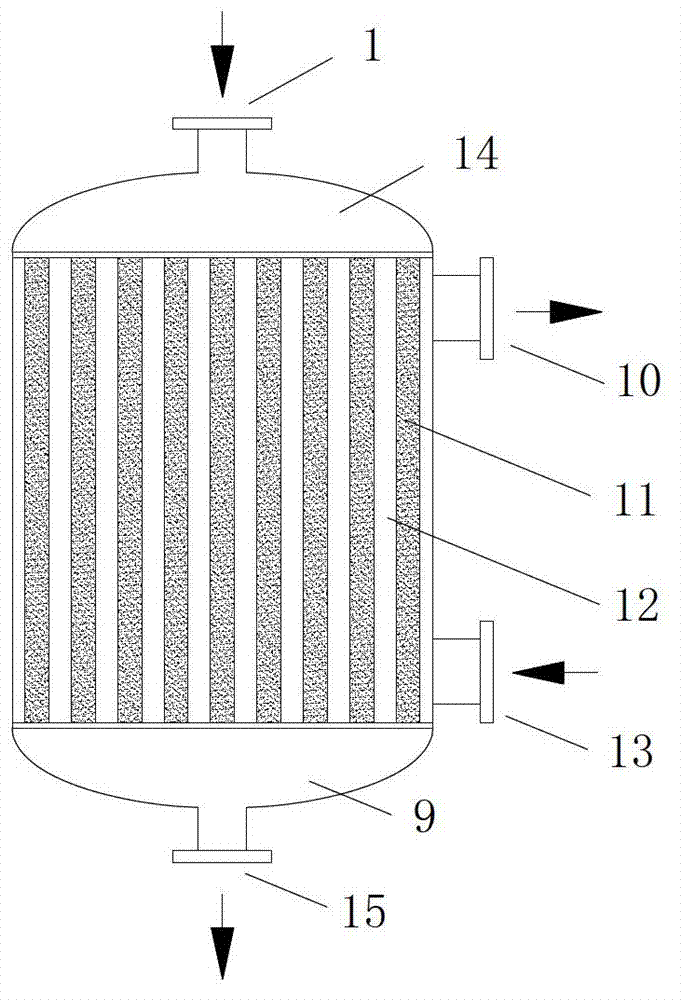

Fixed bed reactor and method for preparing maleic anhydride by virtue of normal butane oxidation

A fixed bed reactor, n-butane technology, applied in chemical instruments and methods, organic chemistry, chemical/physical processes, etc., can solve the problem of uneven distribution of reactant gas flow, catalyst can not be used uniformly, n-butane conversion rate It can improve the utilization rate of catalyst, improve the influence of uneven local impact, and improve the conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

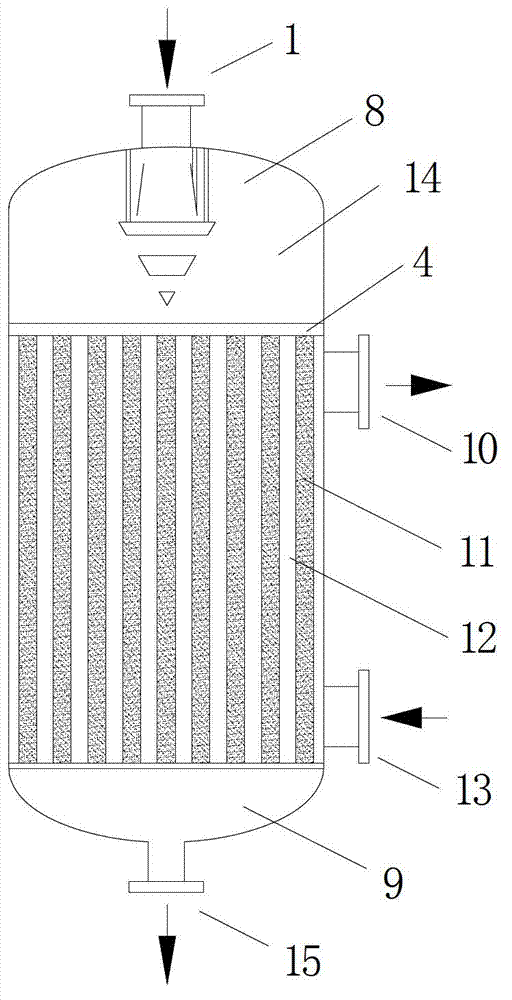

[0054] like image 3 , Figure 4 As shown, it is the gas pre-distributor of the fixed bed reactor of the present invention, including the flow deflector 2 arranged above the gas inlet 1 of the fixed bed reactor, the top of the flow deflector 2 is provided with a gas distribution plate 4, and the flow deflector The deflector 2 is supported in the direction of the gas outlet of the gas inlet 1 of the fixed bed reactor through four deflector support rods 5. The deflector 2 is a conical deflector. Of course, the deflector 2 can also choose a hemispherical deflector. The wall surface of the deflector 2 is provided with a hollow part, and the hollow part of the wall surface of the deflector 2 is a first annular slit distributed along the radial direction of the deflector 2 . The first annular slit distributed along the radial direction of the deflector 2, the deflector 2 after the slit uses three straight rods 6 as a supporting framework, which is shaped like a cone and cuts out se...

Embodiment 2

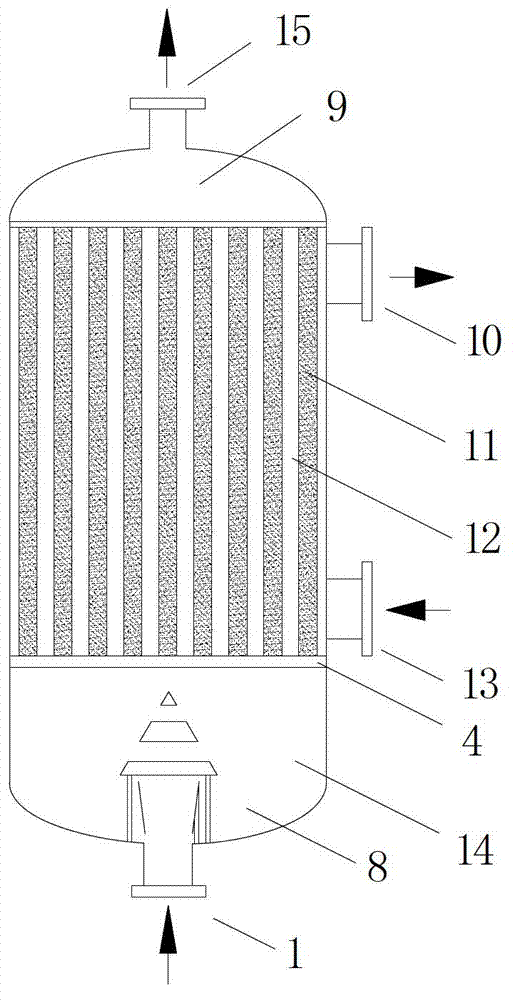

[0059] like Figure 5 As shown, it is the gas pre-distributor of the fixed bed reactor of the present invention, including the flow deflector 2 arranged above the gas inlet 1 of the fixed bed reactor, the top of the flow deflector 2 is provided with a gas distribution plate 4, and the flow deflector The deflector 2 is supported in the direction of the gas outlet of the gas inlet 1 of the fixed bed reactor through four deflector support rods 5. The deflector 2 is a hemispherical deflector. Of course, the deflector 2 can also choose a conical deflector. The wall surface of the deflector 2 is provided with a hollow part, and the hollow part of the wall surface of the deflector 2 is a first annular slit distributed along the radial direction of the deflector 2 . The distance between the deflector 2 and the wall surface where the gas inlet 1 of the fixed bed reactor is located is 100 mm to 400 mm. The number of first annular slits distributed along the radial direction of the defl...

Embodiment 3

[0066] like Image 6 As shown, it is the gas pre-distributor of the fixed bed reactor of the present invention, including the flow deflector 2 arranged above the gas inlet 1 of the fixed bed reactor, the top of the flow deflector 2 is provided with a gas distribution plate 4, and the flow deflector The deflector 2 is supported in the direction of the gas outlet of the gas inlet 1 of the fixed bed reactor through four deflector support rods 5. The deflector 2 is a conical deflector. Of course, the deflector 2 can also choose a hemispherical deflector. The wall surface of the deflector 2 is provided with a hollow part, and the hollow part of the wall surface of the deflector 2 is a first annular slit distributed along the radial direction of the deflector 2 . The distance between the deflector 2 and the wall surface where the gas inlet 1 of the fixed bed reactor is located is 100 mm to 400 mm. The deflector 2 is a conical deflector, the number of the first annular slits distrib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com