Flexible mechanical arm vibration reduction device and method based on magneto-rheological technology

A technology of flexible manipulators and vibration damping devices, which is applied in the direction of manipulators, claw arms, manufacturing tools, etc., can solve the problem of difficult implementation of large-scale vibration control of flexible manipulators. Reduces the effect of large vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

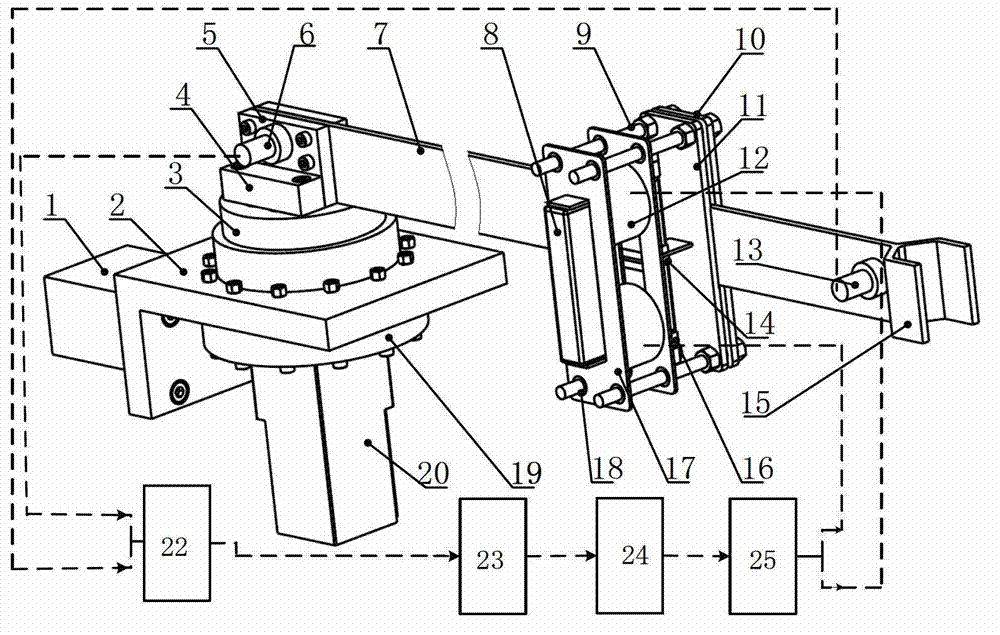

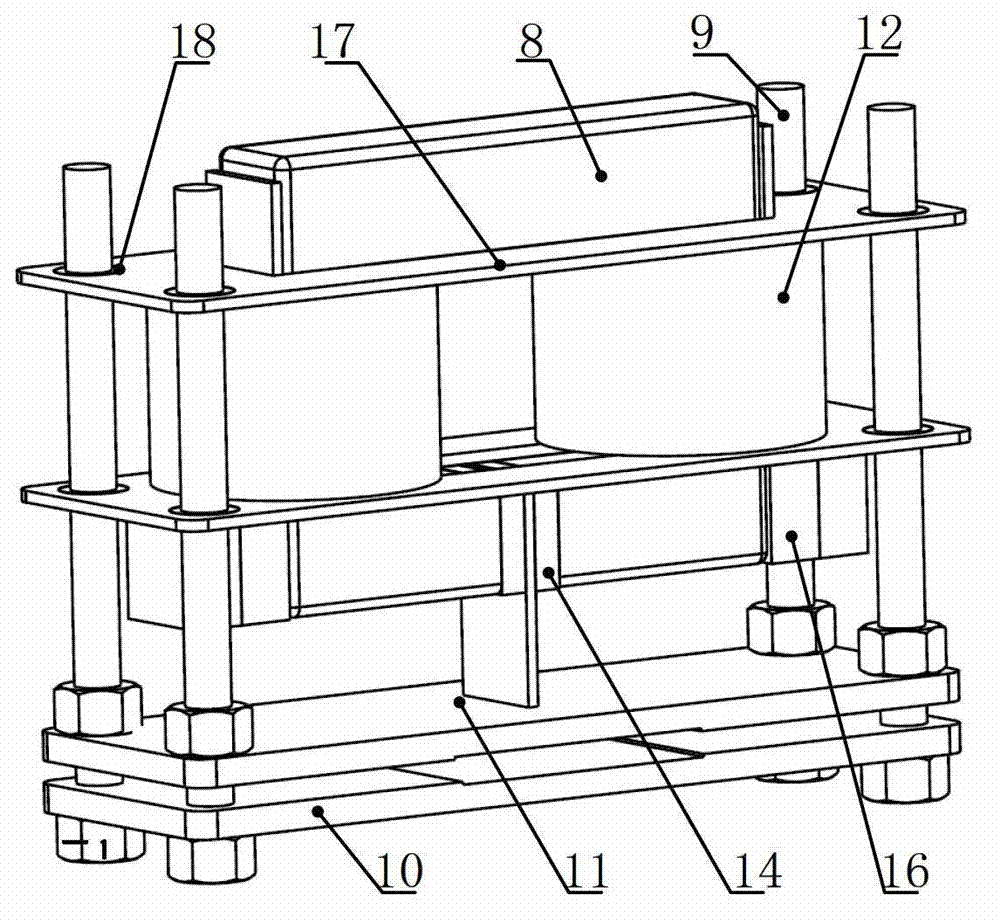

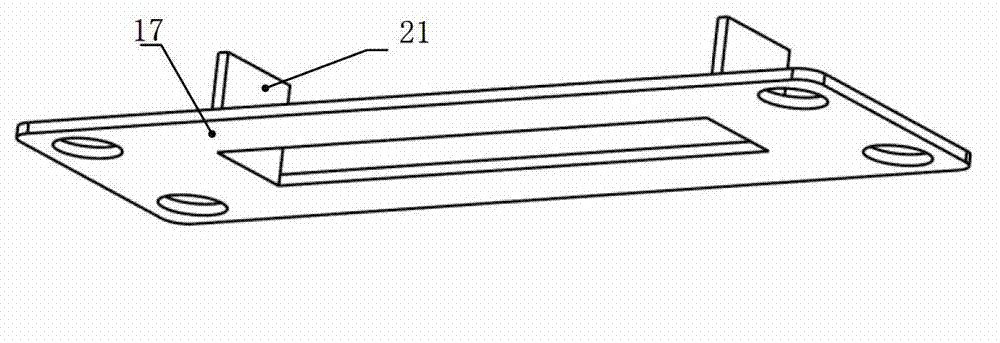

[0037] Such as figure 1 As shown, a flexible manipulator damping device based on magnetorheological technology in the present invention includes a rigid-flexible coupling manipulator, a magnetorheological elastomer damping device installed on the flexible manipulator and a feedback control loop, wherein:

[0038] Rigid-flexible coupled manipulator consists of rigid manipulator 1, motor mounting plate 2, flange plate 3, flexible manipulator mounting base 4, flexible manipulator mounting plate 5, flexible manipulator 7, harmonic reducer 19 and servo motor 20 ;M8 threaded holes are processed on the end surface of the rigid mechanical arm 1, and M8 countersunk holes are processed on the side of the motor mounting plate 2, and the rigid mechanical arm 1 and the motor mounting plate 2 are fixedly connected by M8×16 hexagon socket screws; Harmonic reducer 19 and servo motor 20 are installed on the motor mounting plate 2 through flanges using M5×40 hexagon socket head bolts and M5 nut...

Embodiment 2

[0052] Such as Figure 4 As shown, in the rigid-flexible coupling manipulator, the motor mounting plate 2 can also be designed as a plane "convex" shape, the rigid manipulator 1 is made of rectangular steel, the large end of the plane of the motor mounting plate 2 is used to install the motor, and the small end of the plane is through the M8 The ×70 bolts and M8 nuts are connected to the rigid mechanical arm 1. The other end of the rigid mechanical arm 1 is mounted on the flange through M8×65 screws, and the flange is connected to the servo motor and harmonic reducer fixed on the base through M8×16 screws, thus forming a A 2R robotic arm system. The two servo motors 26 are respectively driven by two supporting drivers 27, and the drivers 27 are controlled by the PC upper computer 24 through the PMAC lower computer 28. Affected by the nominal motion of the manipulator, the natural frequency of the flexible manipulator 7 will change as the motion state of the rigid manipulator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com