Multifunctional on-site mixed loading explosive truck

A multi-functional technology for mixing explosives on site, applied in explosives, explosives processing equipment, offensive equipment, etc., can solve the problem of exposed pipelines, hydraulic pipelines and control cables, and the small range of emulsified granular ammonium oil explosives, which cannot be realized Problems such as mixed loading of multiple types of explosives to achieve the effect of improving charge efficiency, wide charge range and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

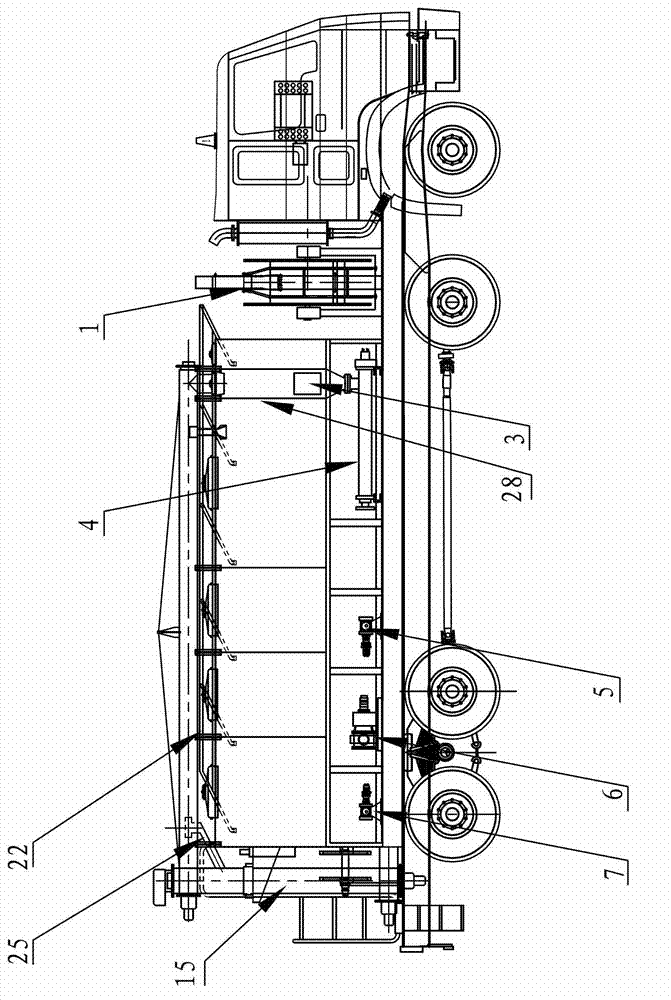

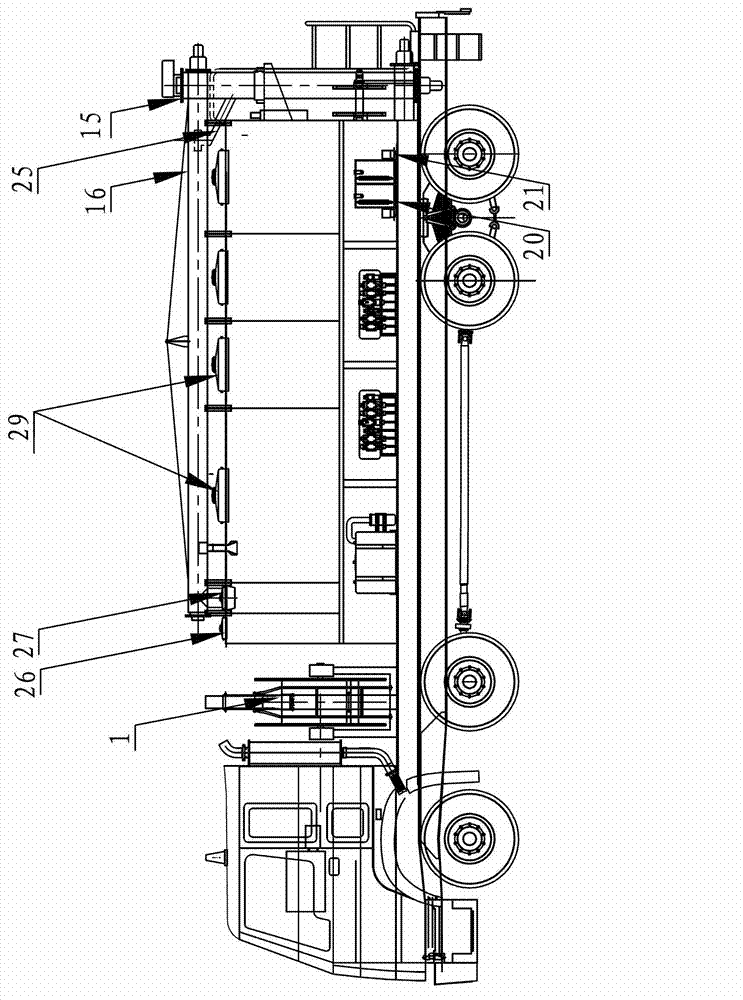

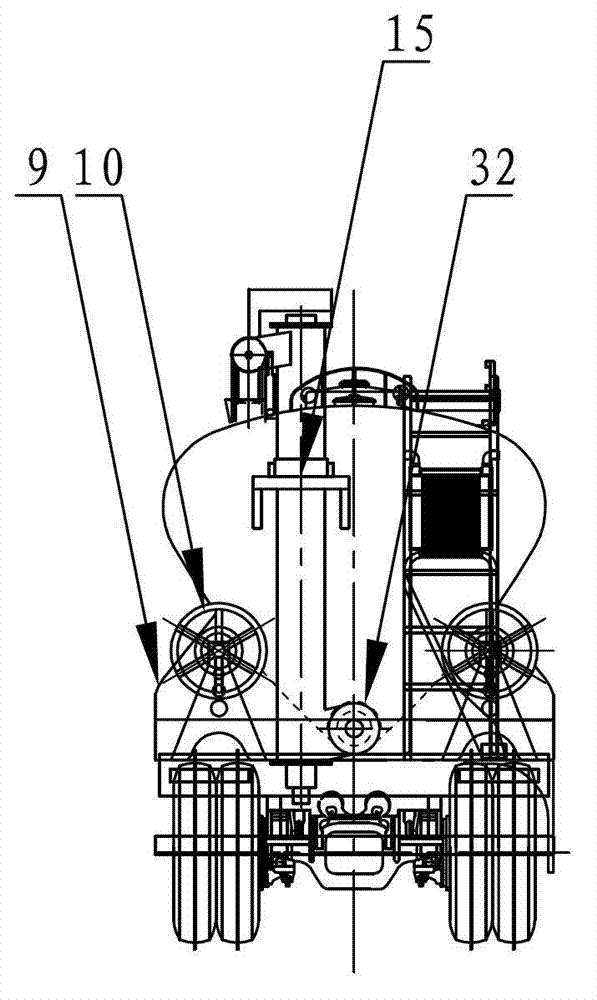

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a multifunctional on-site mixed explosives vehicle is composed of a chassis part and an upper plate part. The key lies in that the upper plate is equipped with a large-diameter hose delivery mechanism 1, a material box, a drug delivery pump 4, and a substrate pump 6. , a diesel pump 7 and a small-diameter hose delivery mechanism 10, the feed box is divided into a diesel bin 26, a water bin 27, a hopper bin 28 and at least four raw material bins 29 by a partition, and the bottom of the bin is provided with a bottom screw 32, the bottom screw 32 is separated from each raw material bin 29 through the bottom cover, the bottom screw 32 communicates with the top screw 16 on the top of the material box through the vertical screw 15, and the outlet of the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com