Emulsion type metal cutting fluid

A metal cutting fluid, emulsified technology, applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of affecting service life, hardness and strength reduction, etc., to improve tool durability, reduce cutting temperature, and suppress chip accumulation tumor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

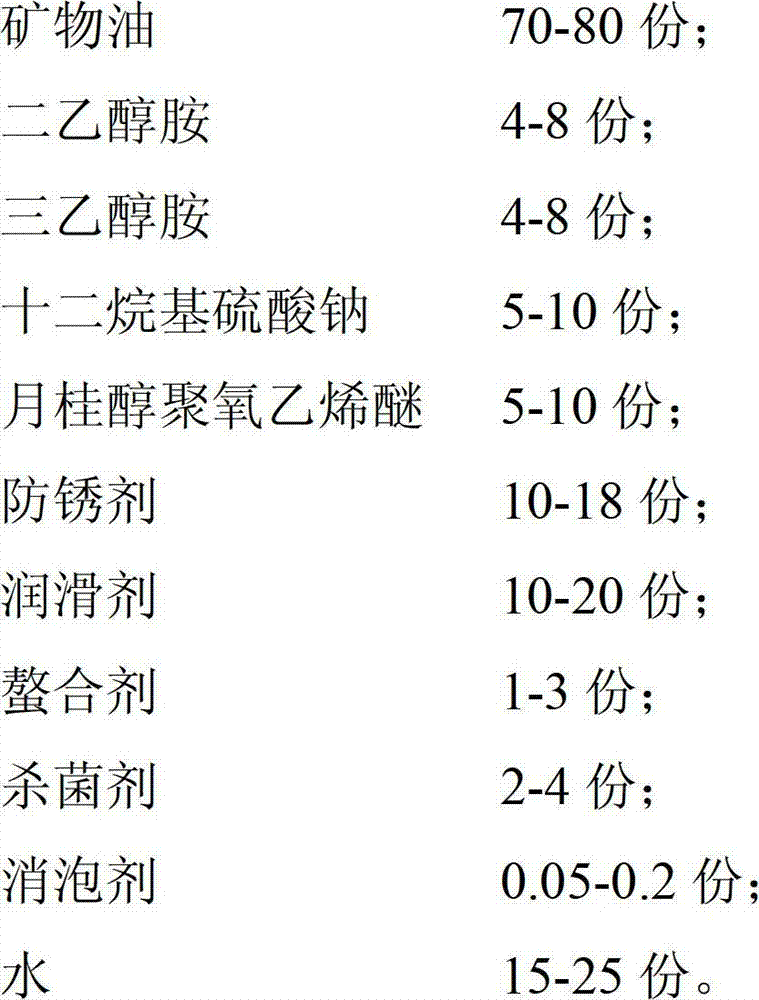

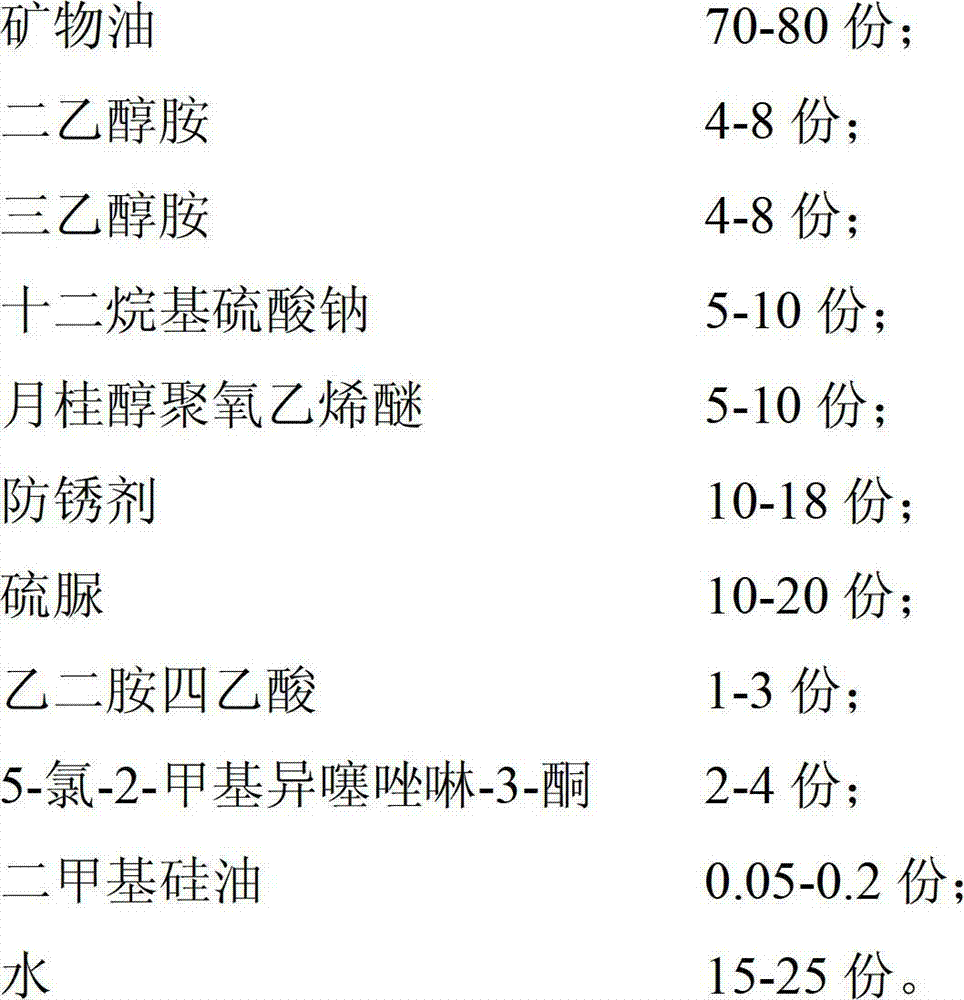

Method used

Image

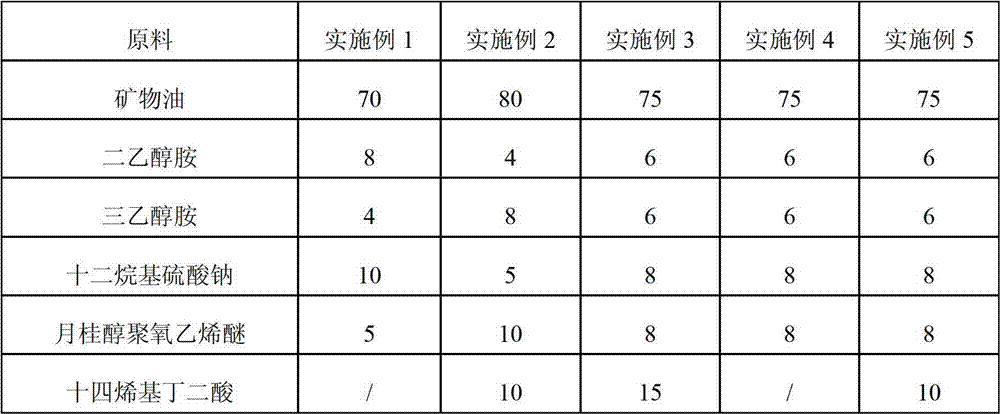

Examples

Embodiment 1

[0023] According to the data of Example 1 corresponding to Table 1, each raw material was weighed to prepare the emulsified metal cutting fluid.

Embodiment 2

[0025] According to the data of Example 2 corresponding to Table 1, each raw material was weighed to prepare the emulsified metal cutting fluid of the present invention.

Embodiment 3

[0027] According to the data of Example 3 corresponding to Table 1, each raw material was weighed to prepare the emulsified metal cutting fluid of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com