Bimetal composite pipe and production method thereof

A bimetallic composite pipe and production method technology, applied to pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of reduced service life of pipes, short length of composite pipes, high probability of damage, etc., and achieve cost saving The effect of material reduction, cost reduction, and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

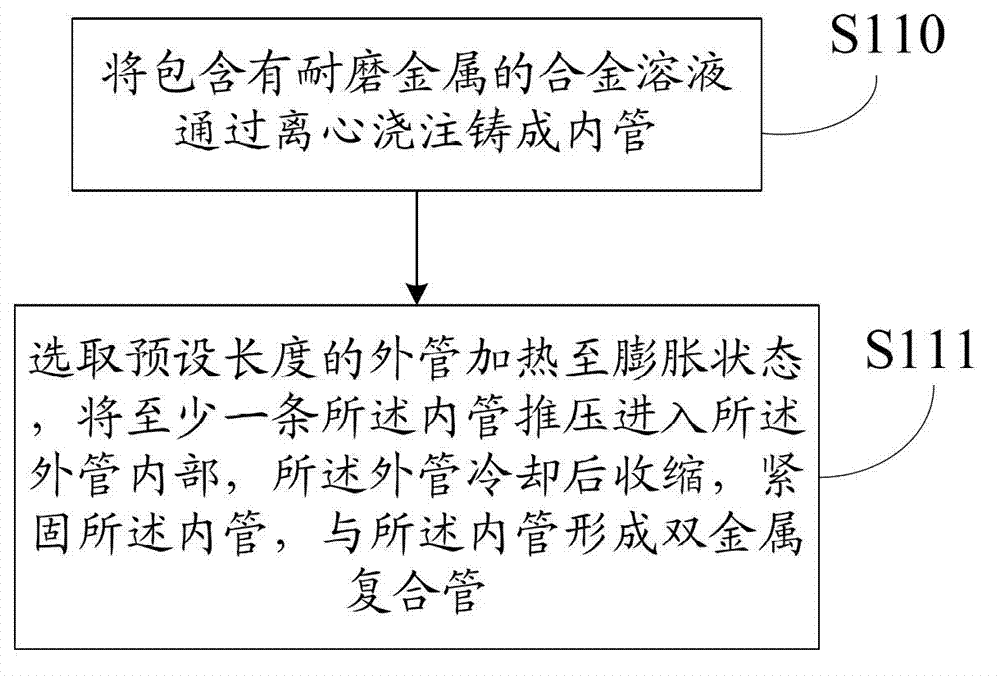

[0044] Embodiment 1 of the present invention provides a production method of bimetal composite pipe, see figure 1 shown, including steps:

[0045] Step S110: casting the alloy solution containing the wear-resistant metal into the inner tube by centrifugal casting.

[0046] In the embodiment of the present invention, the inner tube is cast by centrifugal casting, but different from the prior art, when performing centrifugal casting, the alloy solution containing wear-resistant metal is injected into the inner tube mold, and the centrifugal casting is formed Finally, the inner tube is separated from the mold to form a separate inner tube, that is, the inner tube is first cast and then assembled with the outer tube. It is not that the inner tube is centrifugally cast and formed and combined with the outer tube to form a bimetallic composite tube, so the length of the outer tube is not limited by the length of the inner tube, and multiple inner tubes can be pushed into an outer t...

Embodiment 2

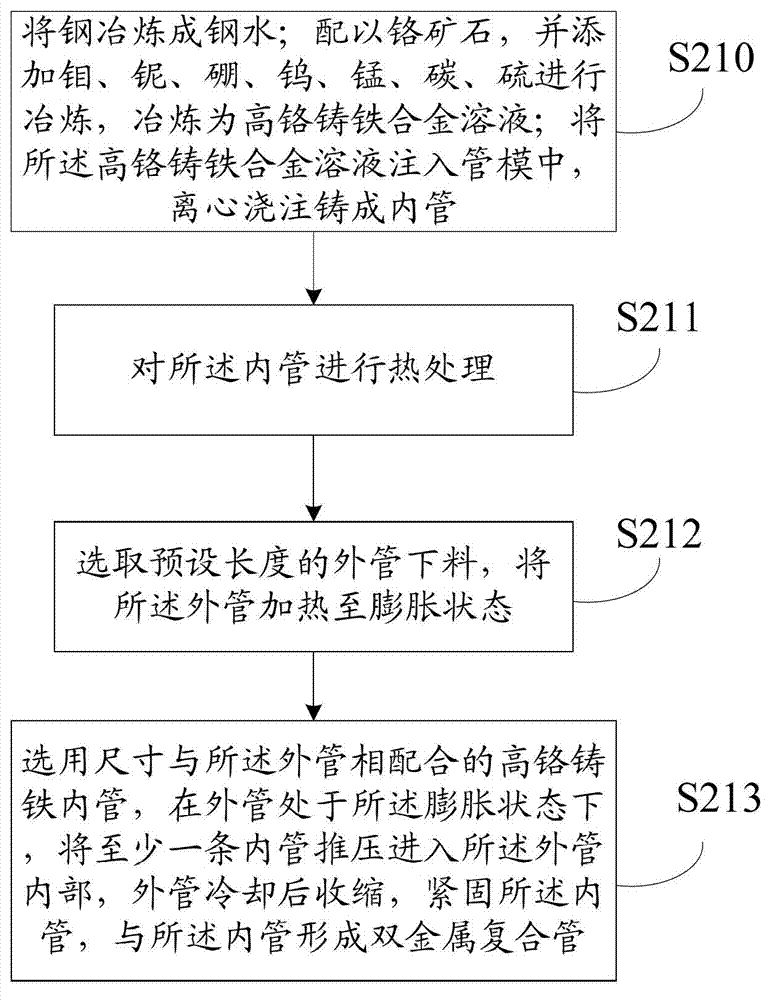

[0064] Embodiment 2 of the present invention provides a kind of bimetal composite pipe production method, see image 3 shown, including steps:

[0065] Step S210: Smelting steel into molten steel; adding chromium ore according to the chromium content of 10-30%, and adding molybdenum, niobium, boron, tungsten, manganese, carbon, and sulfur for smelting, and smelting into a high-chromium cast iron alloy solution; The high chromium cast iron alloy solution is poured into the pipe mold, and the inner pipe is cast by centrifugal casting.

[0066] In this embodiment, the wear-resistant metal is also chromium, and the alloy solution is a high-chromium cast iron solution with a chromium content of 10%-30% by mass percentage.

[0067] Preferably, steel materials below No. 20 are selected as raw materials for smelting, and more preferably, scrap steel can be selected to reduce production costs.

[0068] Those skilled in the art know that the 20 in the No. 20 steel here refers to the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com