Method for strip testing of mems devices, testing strip of mems devices and mems device thereof

A device and strip technology, applied in the field of MEMS device, its strip test and its test strip field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

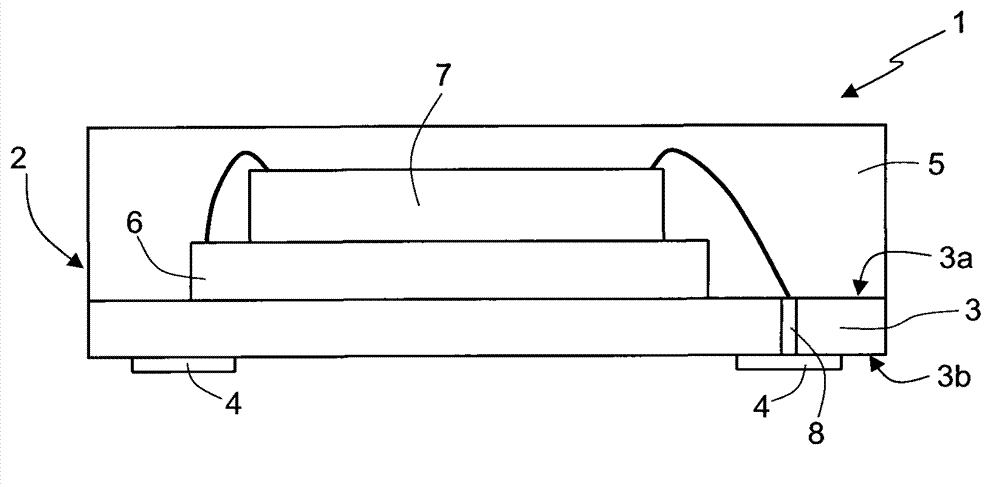

[0035] The present inventors have recognized that the co-mold compound surrounding the various MEMS devices in the test strip is responsible for residual stress acting on the same devices and skewing the testing process.

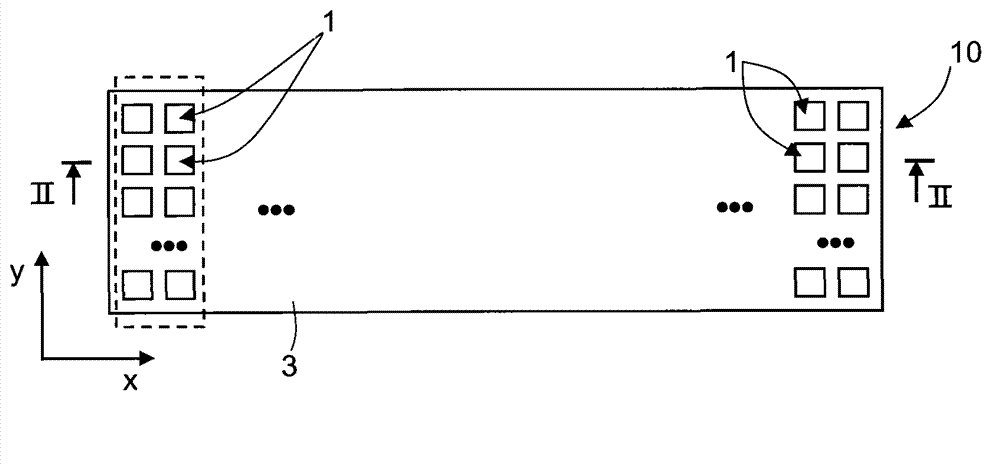

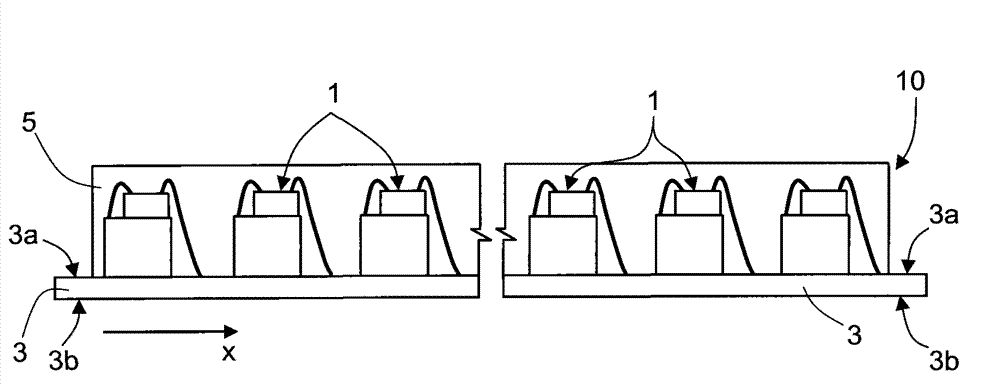

[0036] Therefore, if Figure 4 (where the same numerals denote the same elements as disclosed above, which will not be described hereinafter), a first aspect of the invention contemplates removing the surrounding strip, for example via a cutting or excision operation, prior to performing the test operation. 10 of the molding compound 5 for the entire thickness of the MEMS device 1 . The cutting performed also extends through the inner surface part of the substrate 3 (starting from the inner surface 3a on which the die of the MEMS device 1 is arranged), which part is removed so as to leave only a gap between the adjoining MEMS devices 1 between the remaining substrate portions indicated by 12. These remaining substrate portions 12 (consisting of the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com