Spring tooth pick-up device

A spring-tooth and elastic technology, applied in the field of nylon spring-tooth pick-up and conveying devices, can solve the problems of large impact of materials, high miss-picking rate, loss, etc., to avoid rigid impact, ensure normal operation, and reduce the effect of miss-checking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

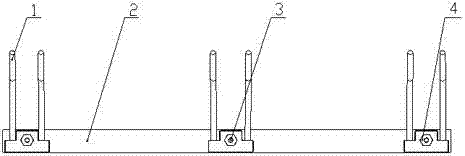

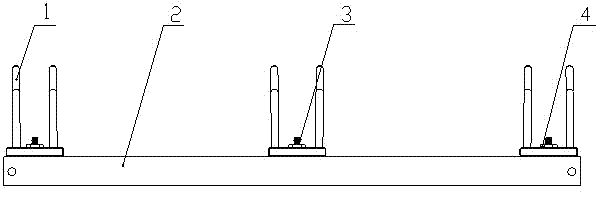

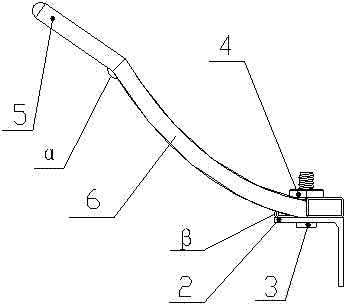

[0019] The spring tooth pick-up device includes a supporting plate 2 and three sets of finger rods 1 evenly distributed on the same surface of the supporting plate 2 , and the finger rods 1 are fixedly connected with the supporting plate 2 through screws 3 and nuts 4 . Each set of finger rods 1 includes two finger rods 1, the finger rods 1 are made of nylon material, and the angle β between the finger rods 1 and the supporting plate 2 is 20°. The finger bar 1 includes a finger bar end 5 and a finger bar root 6 connected as one, and the finger bar end 5 is fixed on the supporting plate 2 through the finger bar root 6; the finger bar end 5 and the finger bar The angle α between the roots 6 is 158°. The end portion 5 of the finger bar is linear, the root portion 6 of the finger bar is arc-shaped, and the arc of the root portion 6 of the finger bar is 0.7 rad.

[0020] When working, install the supporting plate 2 of the elastic tooth picking device on the conveying chain. When th...

Embodiment 2

[0022] The spring tooth pick-up device includes a supporting plate 2 and three sets of finger rods 1 evenly distributed on the same surface of the supporting plate 2 , and the finger rods 1 are fixedly connected with the supporting plate 2 through screws 3 and nuts 4 . Each set of finger rods 1 includes two finger rods 1, the finger rods 1 are made of nylon material, and the angle β between the finger rods 1 and the supporting plate 2 is 35°. The finger bar 1 includes a finger bar end 5 and a finger bar root 6 connected as one, and the finger bar end 5 is fixed on the supporting plate 2 through the finger bar root 6; the finger bar end 5 and the finger bar The angle α between the roots 6 is 172°. The end portion 5 of the finger bar is linear, the root portion 6 of the finger bar is arc-shaped, and the arc of the root portion 6 of the finger bar is 1.1 rad.

Embodiment 3

[0024] The spring tooth pick-up device includes a supporting plate 2 and three sets of finger rods 1 evenly distributed on the same surface of the supporting plate 2 , and the finger rods 1 are fixedly connected with the supporting plate 2 through screws 3 and nuts 4 . Each set of finger rods 1 includes two finger rods 1, the finger rods 1 are made of nylon material, and the angle β between the finger rods 1 and the supporting plate 2 is 30°. The finger bar 1 includes a finger bar end 5 and a finger bar root 6 connected as one, and the finger bar end 5 is fixed on the supporting plate 2 through the finger bar root 6; the finger bar end 5 and the finger bar The angle α between the roots 6 is 165°. The end portion 5 of the finger bar is linear, the root portion 6 of the finger bar is arc-shaped, and the arc of the root portion 6 of the finger bar is 0.9 rad.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com