Heat dissipation frame manufacturing method and products thereof

A heat dissipation frame and manufacturing method technology, applied in the field of heat dissipation frame manufacturing and its products, can solve the problems of high production cost, limited heat conduction efficiency of heat dissipation structure, etc., achieve the effects of reducing the consumption of man-hours, saving processing steps, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

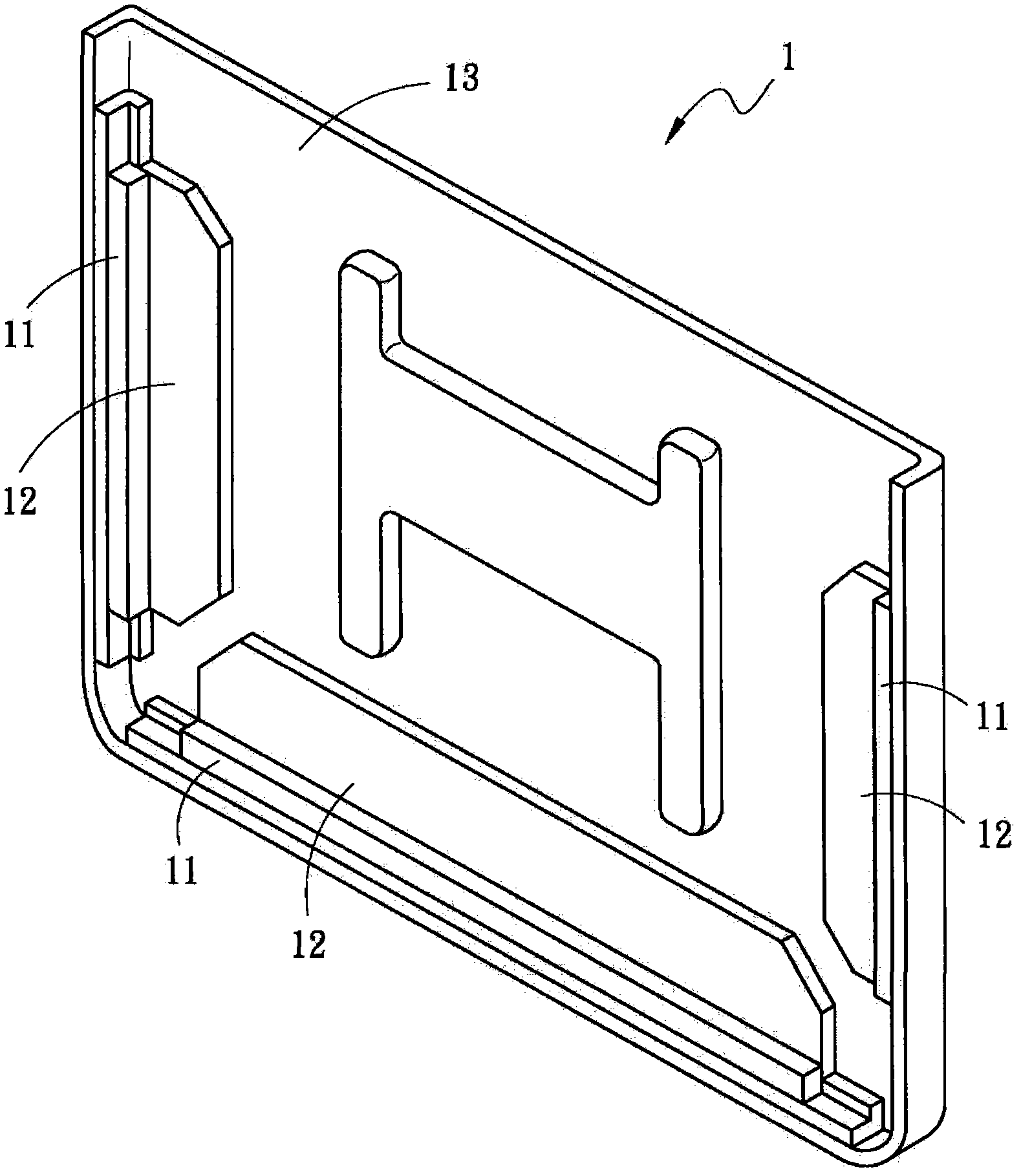

[0025] Relevant detailed description and technical content of the present invention, now just explain as follows with respect to matching drawing:

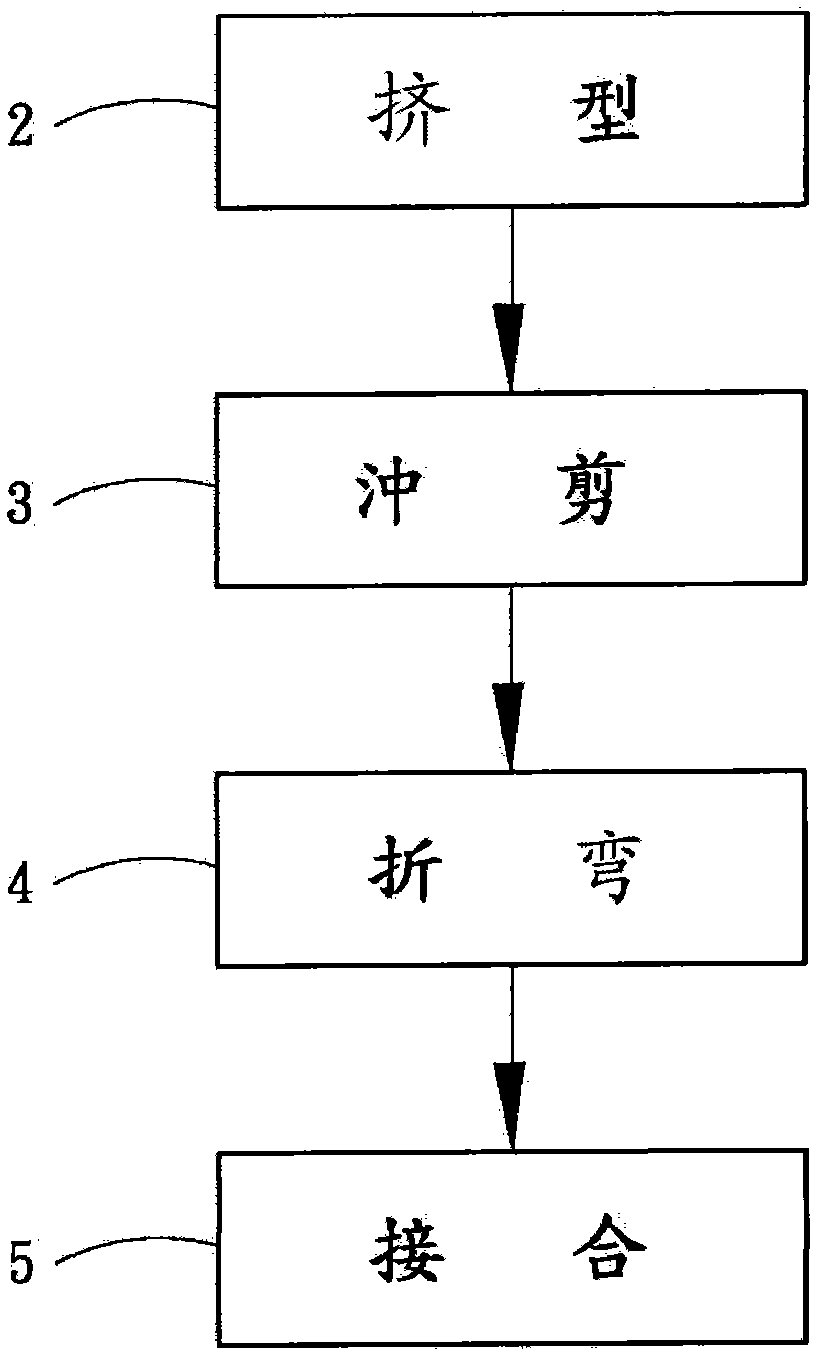

[0026] see figure 2 As shown, the present invention provides a method for manufacturing a heat dissipation frame, which includes the following steps:

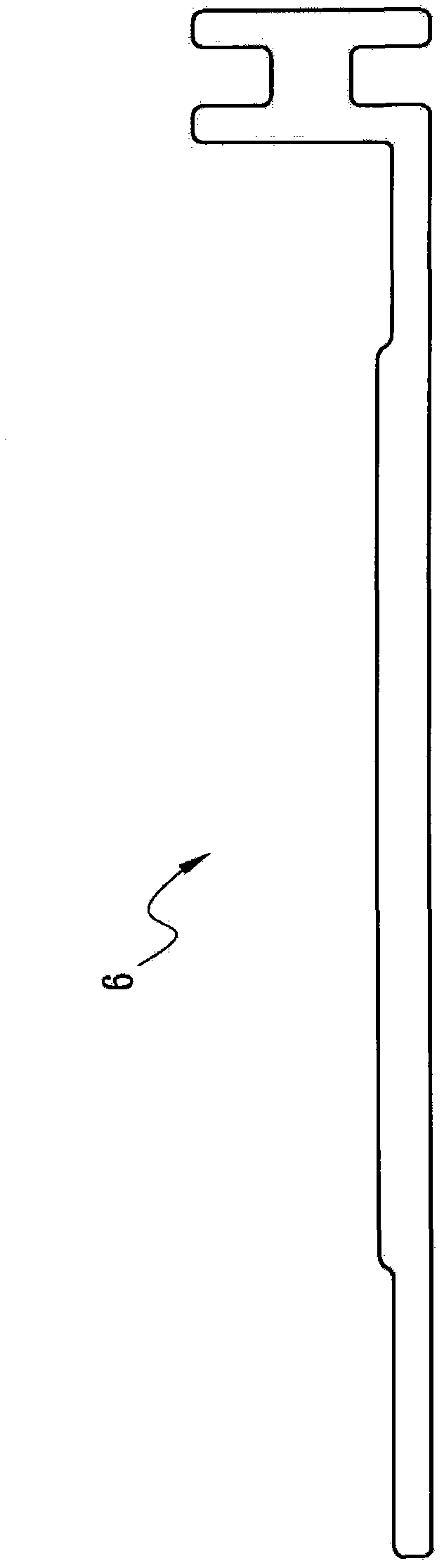

[0027] a. Extrusion Step 2: Extrude the aluminum material into the initial shape of the heat sink.

[0028] b. Punching and shearing step 3: After measuring according to the required size specifications, perform partial punching and shearing at the place where the long side of the heat sink prototype is to be bent to form multiple punching and shearing gaps.

[0029] c. Bending step 4: Bending the initial form of the heat sink at the punching and shearing gap and butting with each other to form multiple bending angles.

[0030] d. Joining step 5: Joining and fixing the butt joints of the punching and shearing notches and the joints of the head and tail joints of the bent heat si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com