Controllable oiling device for roadside wheel track of railway

A technology of oiling and railway, which is applied in the direction of railway car body parts, railway auxiliary equipment, track lubrication, etc. It can solve the problems of affecting service life, polluting the environment, and large waste of lubricating oil, so as to achieve no waste of lubricating grease and prolong service life , good lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

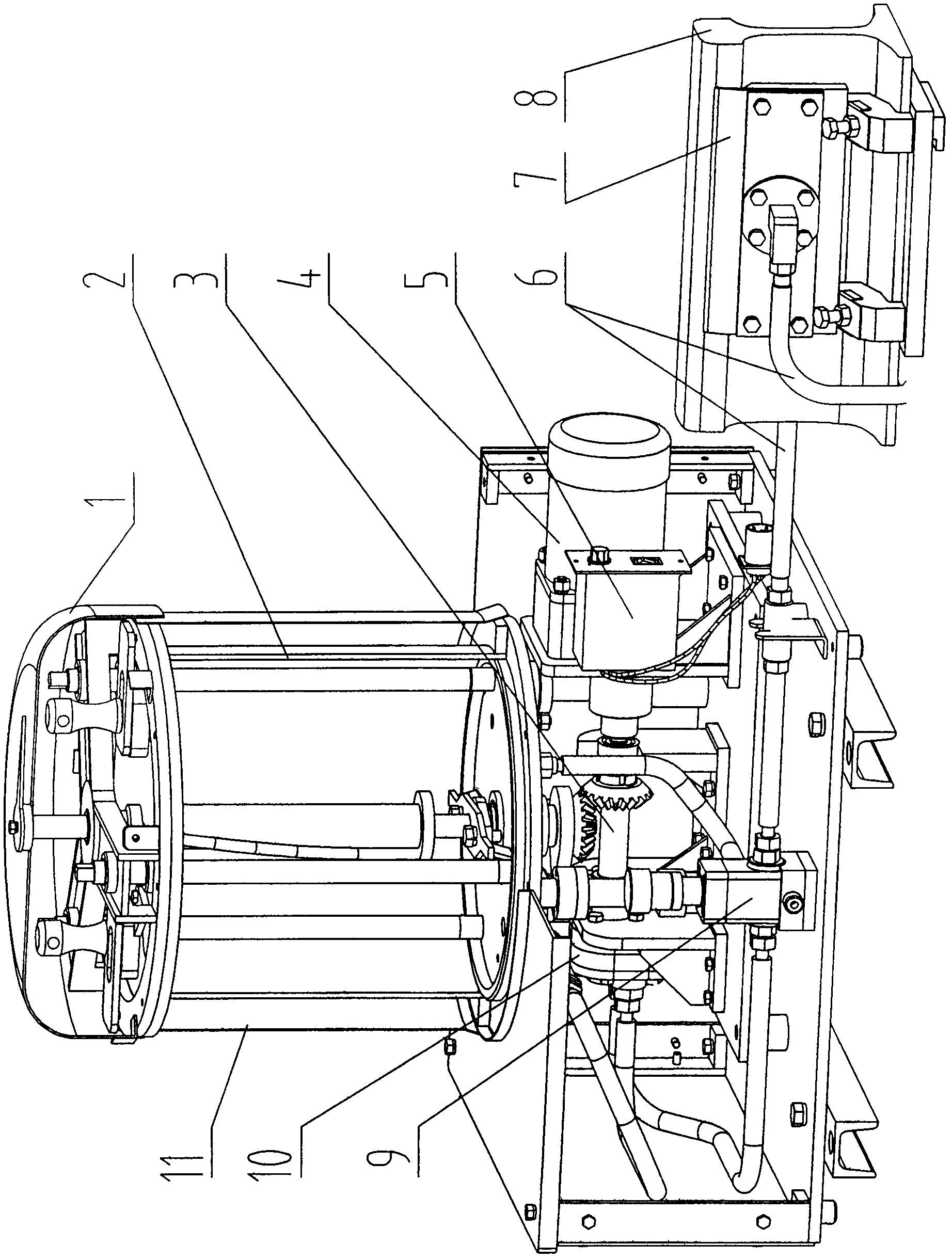

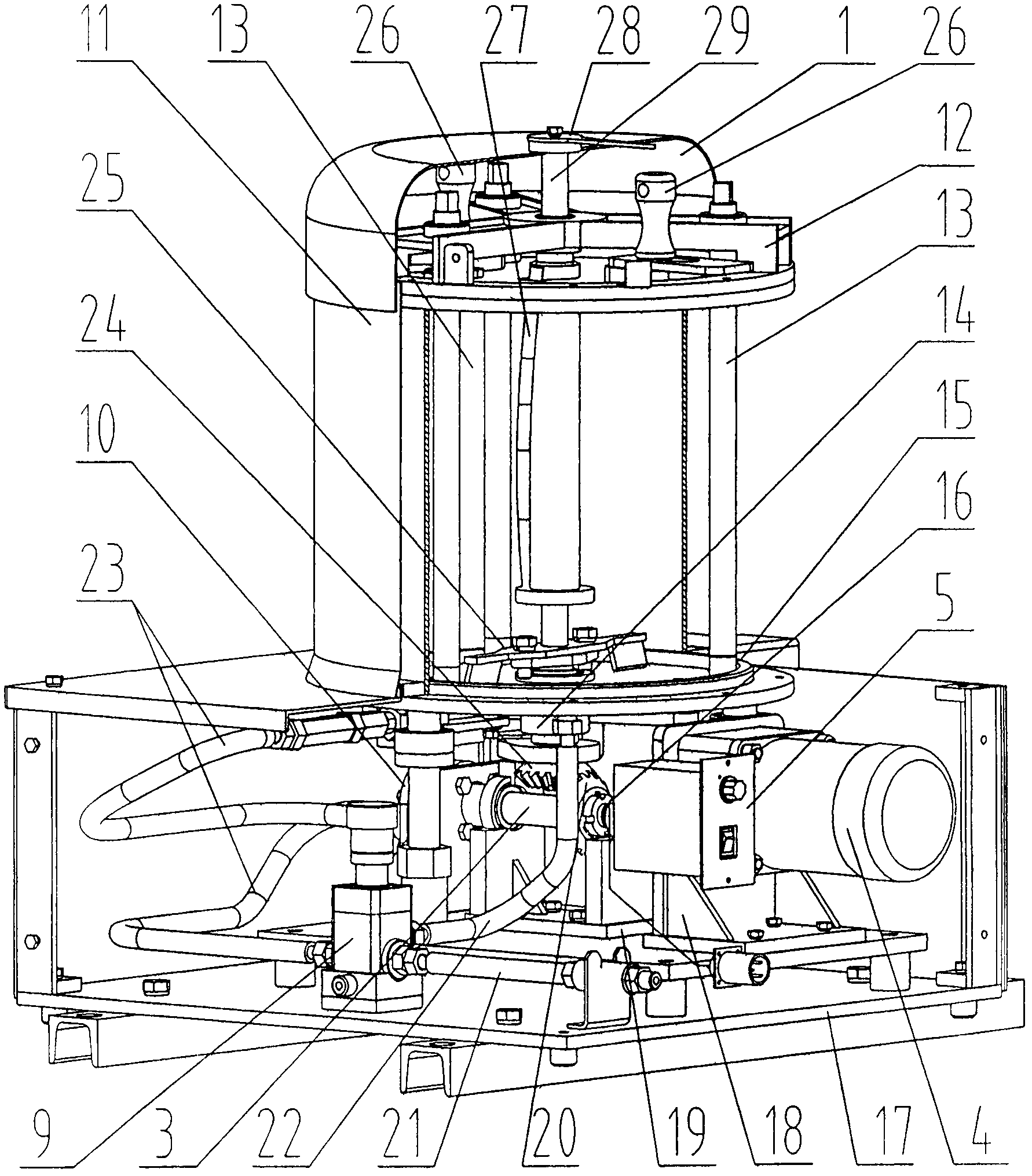

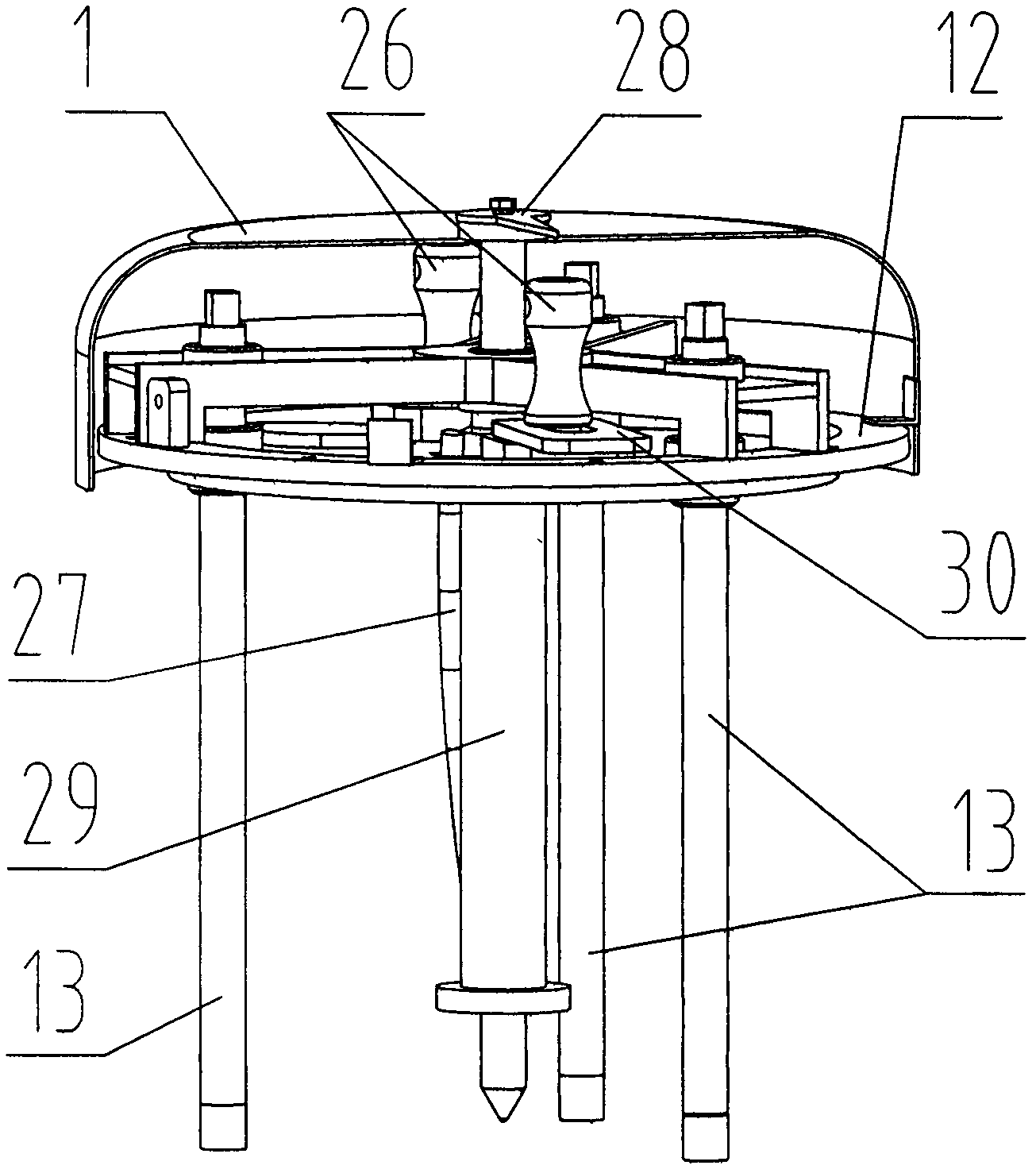

[0013] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 It is shown that a specific embodiment of the present invention is: a controllable lubricator for railway trackside wheels and rails, comprising an oiling plate, an oiling plate fixing plate, a motor, an oil pump, an oil storage tank, and pipelines. Its structural features are: the motor 4 is fixed on the support 18, the power of the motor 4 is transmitted to the oil pump input shaft 3 through the coupling 16 on the one hand; on the other hand, it is transmitted to the blade shaft through the bevel gear 20 on the oil pump input shaft 3 The bevel gear 24 of 14 ends. The oil pump input shaft 3 is supported on the support 19, the stirring blade 25 is fixed on the other end of the blade shaft 14, the blade shaft 14 is fixed on the bottom plate 15 of the oil storage tank, and one end of the pointer shaft 29 is loosely supported on the blade shaft 14. In the central hole, the other end passes through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com