Taking-off and landing system of shipboard aircraft of aircraft carrier and taking-off and landing method thereof

A technology for aircraft carriers and carrier-based aircraft, which is applied to aircraft carriers, motor vehicles, parking devices, etc., and can solve the problems of occupying the space of the aircraft carrier, difficult to implement, difficult to maintain and use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

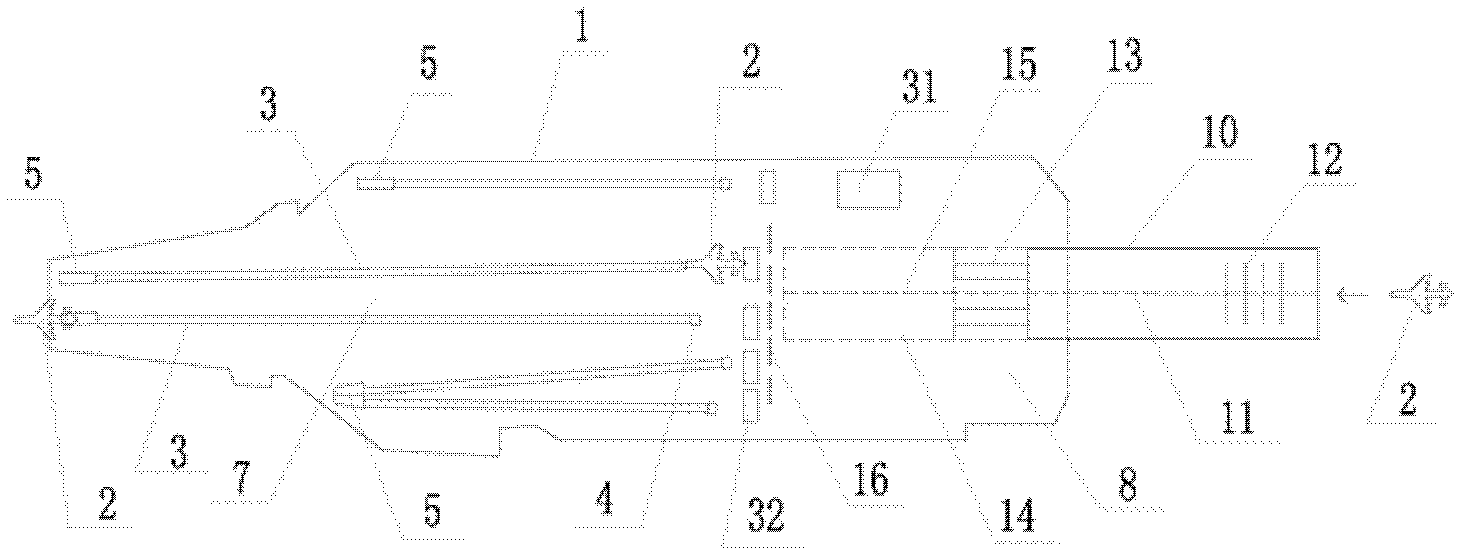

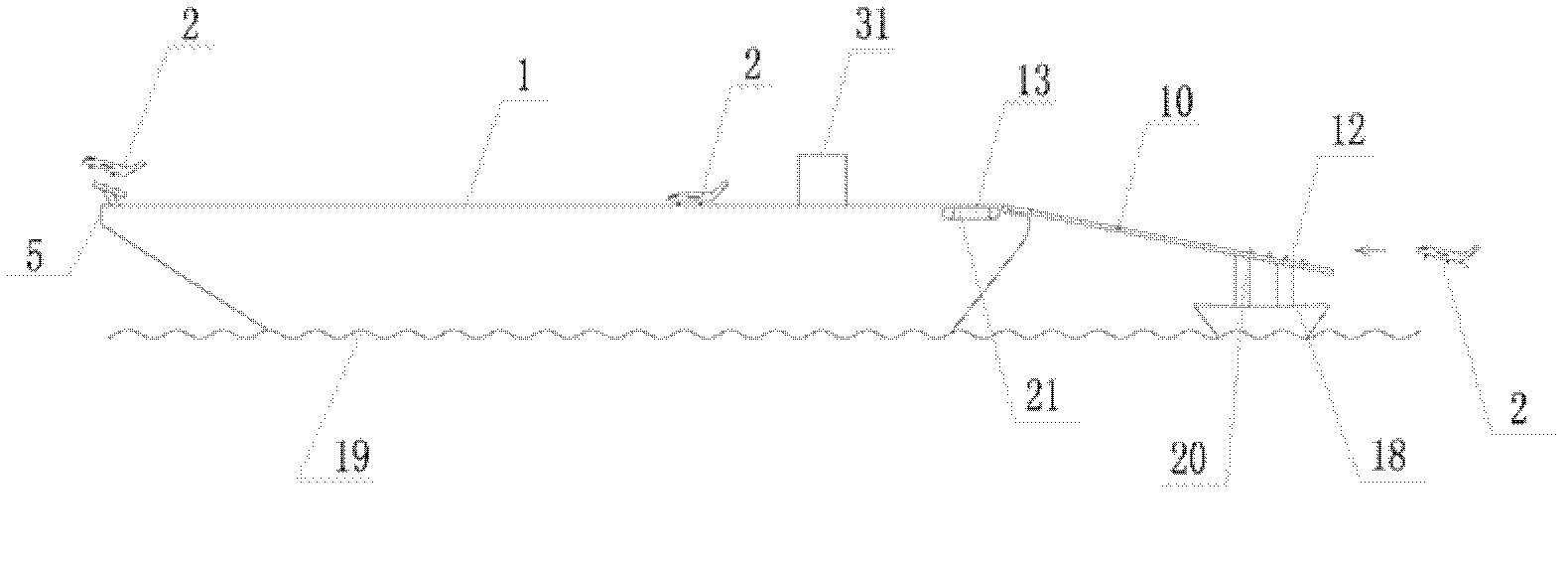

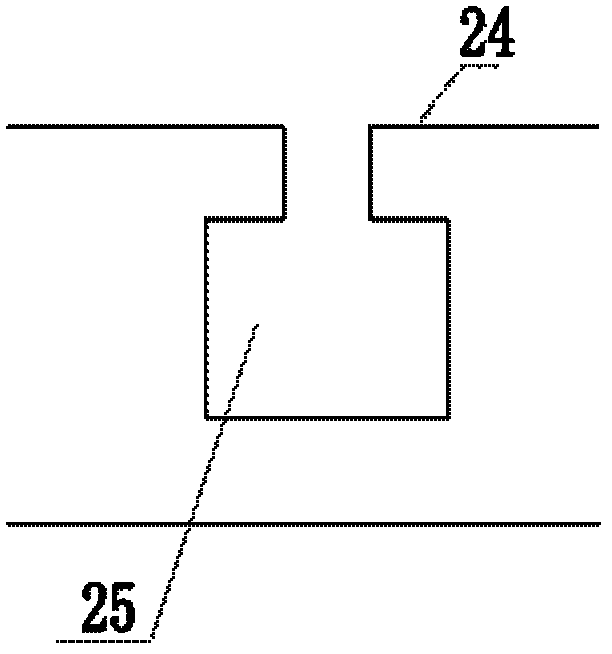

[0232] Such as Figure 1-6 As shown, the bow jump-up deck 5 is arranged on the bow of the aircraft carrier, and is a runway deck that can bounce up the carrier-based aircraft 2; the bow jump-up deck 5 is slightly longer than the distance between the front and rear wheels of the carrier-based aircraft 2 , slightly wider than the width between the left and right wheels of the carrier aircraft 2; the upward elastic force of the bow catapult deck 5 comes from electromagnetic catapult force, steam catapult force, or other such as hydraulic power, pneumatic power, mechanical force; The rear end of the bow lift deck 5 is continuous with the front end of the track groove 3; the track groove 3 is located at the take-off area 7 of the aircraft carrier 1, and the carrier aircraft from the take-off line 4 of the carrier aircraft 2 to the rear end of the bow lift deck 5 2 below the take-off runway deck; the track guide 26 is fitted in the track groove cavity 25, and the track guide 26 is a...

Embodiment 2

[0243] The take-off and landing use method of the carrier-based aircraft take-off and landing system of the aircraft carrier described in the present invention comprises the following steps:

[0244] Step 1: The carrier-based aircraft 2 parked on the deck of the aircraft carrier 1 arrives at the take-off line 4, and the connecting rod under the front landing gear of the carrier-based aircraft 2 is flexibly connected with the buckle mechanism 28 on the upper part of the track guide, and the guide at the rear of the take-off line 4 Flow plate 32 supports;

[0245] Step 2: After receiving the take-off preparation command, the engine of the carrier-based aircraft 2 is ignited. If the booster guide is used, the booster engine 30 connected to it is ignited in good time. After receiving the take-off command, the carrier-based aircraft 2 starts to roll;

[0246] Step 3: Limited and guided by the track guide, the carrier-based aircraft 2 accelerates and rolls forward along the track sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com