High-efficient process system for slime water through drifting separation

A coal slime water and high-efficiency technology, applied in water/sludge/sewage treatment, water/sewage multi-stage treatment, flotation water/sewage treatment, etc., can solve the problems of high cost of civil engineering, inability to remove ash, and large footprint And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

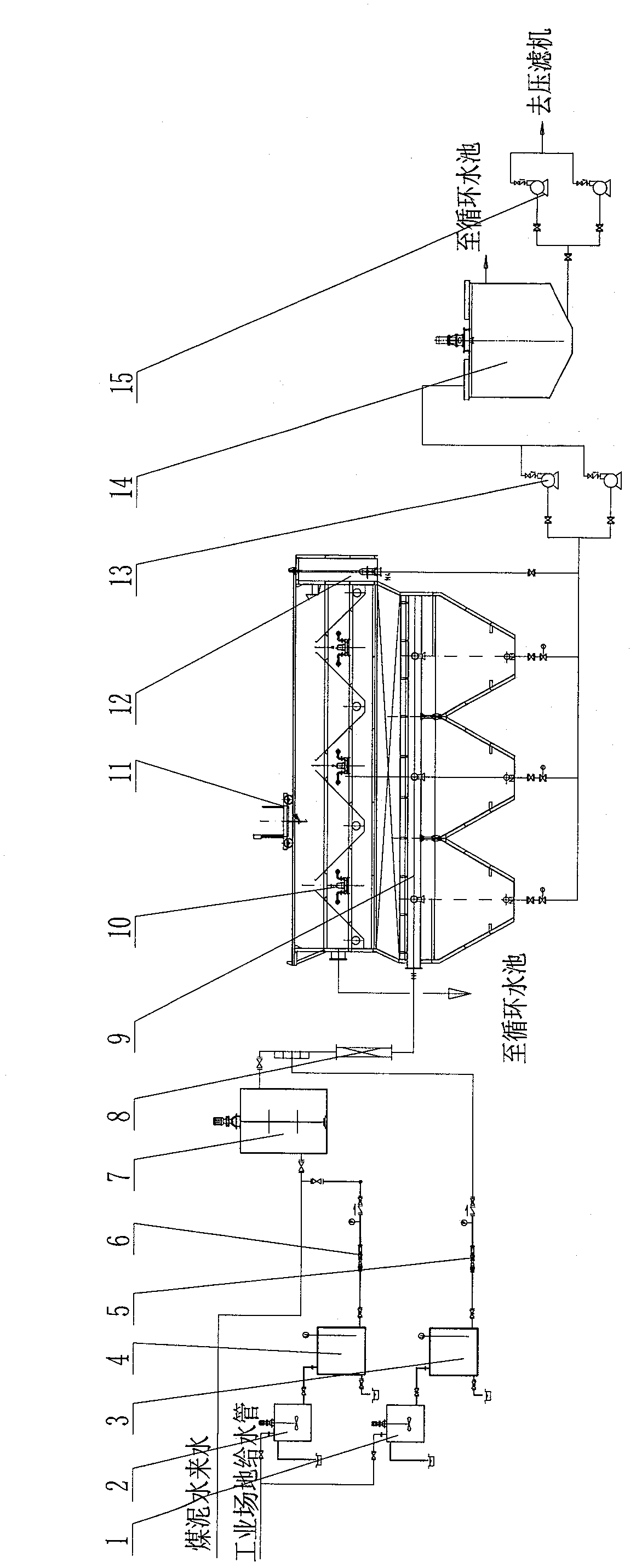

[0016] The fully automatic dosing equipment includes medicine storage barrels, medicine dissolving barrels, medicine delivery and dosing pumps, and the dosing system adds medicine, which is controlled by PLC

[0017] (1) Coal slime water mixing unit

[0018] The slime water mixing unit mainly includes two devices including 7 slime water mixing barrels and 8 static mixers. The main function of the coal slime water mixing tank is to fully mix the added chemicals, so that the particulate matter in the coal slime water can gather and condense into large alum flocs, so that the particulate matter in the water can naturally settle under the action of gravity and remove the particulate matter. , so as to achieve the purpose of mud-water separation. The mixing barrel is mainly composed of stirring motor, stirring barrel, stirring shaft, paddle leaves and other parts. The mixing barrel is welded by steel materials, lined with glass fiber reinforced plastic for anti-corrosion, and ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com