Anti-icing single-component fluorosilicone rubber coating material and preparation method thereof

A technology of fluorosilicone rubber and coating materials, applied in the direction of coating, etc., can solve the problems of short action time of deicing agents, environmental pollution, increased energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

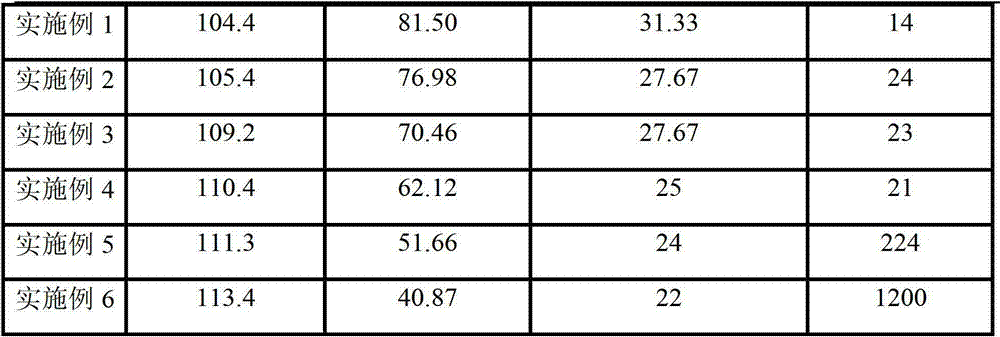

Examples

Embodiment 1

[0024] (1) Step 1, take 100g of α, ω-dihydroxy polydimethylsiloxane in a beaker, add 10g of filler silica, stir well and add 2g of whitening agent TiO 2 , stir evenly;

[0025] (2) Step 2, add 0.25 g of dodecafluoroheptylpropyltrimethoxysilane and 1 g of methyltrimethoxysilane to the uniformly stirred system in step 1, and add the silane coupling agent γ-glycidyl ether after stirring well Oxypropyltrimethoxysilane 1g, stir well;

[0026] (3) In step 3, add 0.2 g of catalyst dibutyltin dilaurate to the uniformly stirred system in step 2, and then add 30 g of solvent xylene, and stir evenly to obtain a one-component fluorosilicone rubber anti-icing coating material.

Embodiment 2

[0028] (1) Step 1, take 100g of α, ω-dihydroxy polydimethylsiloxane in a beaker, add 40g of filler silica, stir well and add 5g of whitening agent TiO 2 , stir evenly;

[0029] (2) Step 2, add 2 g of tridecafluorooctyltrimethoxysilane and 1 g of methyltriethoxysilane to the uniformly stirred system in step 1, and add the silane coupling agent γ-aminopropyltrimethoxy after stirring well base silane 0.5g, stir evenly;

[0030] (3) In step 3, add 0.1 g of catalyst stannous octoate to the uniformly stirred system in step 2, and then add 10 g of solvent toluene, and stir evenly to obtain a one-component fluorosilicone rubber anti-icing coating material.

Embodiment 3

[0032] (1) Step 1, take 100g of α, ω-dihydroxy polydimethylsiloxane in a beaker, add 5g of filler silica, stir well and add 1g of whitening agent TiO 2 , stir evenly;

[0033] (2) Step 2, add 4-methyl-(perfluorohexylethyl)propyltrimethoxysilane 4g and methyltriacetoxysilane 1g to the uniformly stirred system in step 1, stir well and add silane Coupling agent γ-aminopropyltriethoxysilane 2g, stir well;

[0034] (3) In step 3, add 0.5 g of catalyst dibutyltin dilaurate to the uniformly stirred system in step 2, and then add 40 g of solvent ethyl acetate, and stir evenly to obtain a one-component fluorosilicone rubber anti-icing coating material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com