Illegal cooking oil lubricant and preparation method thereof

A technology of waste oil and lubricants, applied in the direction of chemical instruments and methods, drilling compositions, etc., to achieve significant economic benefits, obvious effects, and reduced lubrication coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

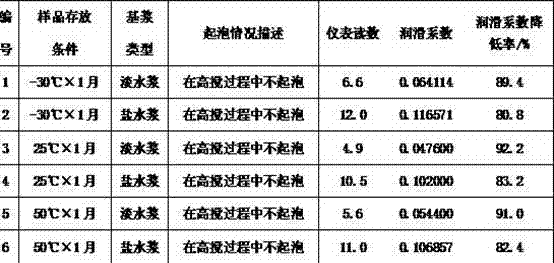

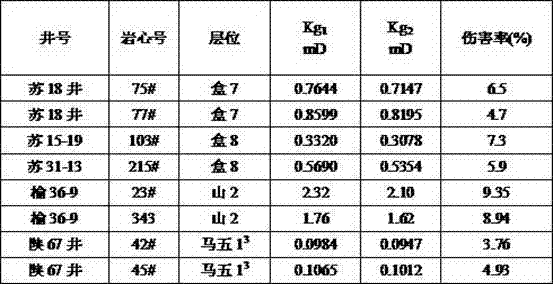

Examples

Embodiment 1

[0027] A gutter oil lubricant, comprising the following components in weight percent: 45% to 55% of gutter oil, 0.8% to 1.2% of sodium sulfite, 1.5% to 2.5% of sorbitan oleate, and 0.025% to 0.035% of antioxidant , extreme pressure antiwear agent 0.22%~0.28%, formaldehyde 0.07%~0.09%, caustic soda 1.0%~1.2%, and the balance is water.

[0028] A preferred embodiment of the present invention is that, in the waste oil, the vegetable oil content is 40%-70%, and the animal oil content is 30%-60%. Waste oil in the prior art is applicable, and this is a preferred embodiment, but not limited thereto.

[0029] Another preferred embodiment of the present invention is that the sodium sulfite is 2.0% of the weight of waste oil, which is preferred, but not limited thereto.

[0030] In the present invention, the sorbitan oleate is preferably sorbitan oleate Span-80, and other types of sorbitan oleate can also be selected.

[0031] In the present invention, the antioxidant is preferably an...

Embodiment 2

[0038] This embodiment is basically the same as the above-mentioned embodiment, the main difference is:

[0039] A waste oil lubricant, comprising the following components in percentage by weight: waste oil 40%, sodium sulfite 0.5%, sorbitan oleate 1%, antioxidant 0.02%, extreme pressure antiwear agent 0.2%, formaldehyde 0.05% %, caustic soda 1.0%, and the balance is water.

[0040] A preparation method of waste oil lubricant, comprising the steps of:

[0041] a. Add waste oil into the closed reaction kettle and start stirring. When the temperature of the reaction kettle reaches 50°C, stir and slowly and evenly add sodium sulfite to react for 90 minutes;

[0042] b. Add sorbitan oleate, stir and react for 20 minutes, add water, then adjust the pH value to 8, stir and react for 8 minutes;

[0043] c. Add extreme pressure anti-wear agent, antioxidant and formaldehyde respectively and stir for 8 minutes to prepare waste oil lubricant for water-based drilling fluid.

[0044] In...

Embodiment 3

[0046] The embodiment is basically the same as the above-mentioned embodiment, the main differences are:

[0047] A waste oil lubricant, comprising the following components in percentage by weight: waste oil 60%, sodium sulfite 1.5%, sorbitan oleate 3%, antioxidant 0.04%, extreme pressure antiwear agent 0.3%, formaldehyde 0.1 %, caustic soda 1.2%, and the balance is water.

[0048] A preparation method of waste oil lubricant, comprising the steps of:

[0049] a. Add waste oil into the closed reaction kettle and start stirring. When the temperature of the reaction kettle reaches 45°C, stir and slowly and evenly add sodium sulfite to react for 70 minutes;

[0050]b. Add sorbitan oleate, stir and react for 15 minutes, add water, then adjust the pH value to 7.5, stir and react for 5 minutes;

[0051] c. Add extreme pressure anti-wear agent, antioxidant and formaldehyde respectively and stir for 5 minutes to prepare waste oil lubricant for water-based drilling fluid.

[0052] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com