Diesel oil pour point depressant and preparation method thereof

A diesel pour point depressant and catalyst technology, applied in the field of pour point depressant, can solve the problems of poor quality of catalytic cracking diesel, inability to achieve pour point depressant effect, inappropriate diesel susceptibility, etc., and achieve good universality, lower freezing point, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

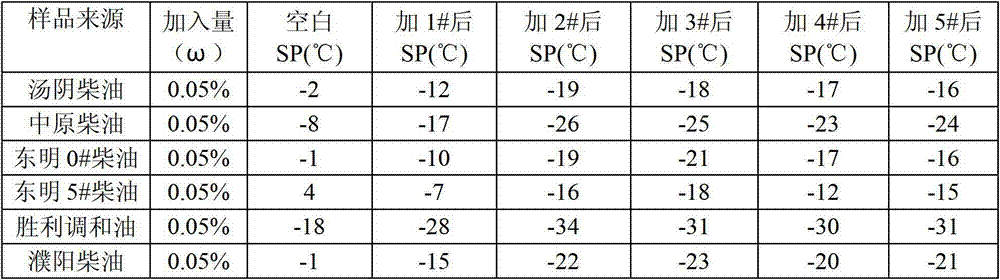

Examples

Embodiment 1

[0022] A preparation method of diesel oil pour point depressant, comprising the steps of:

[0023] Step 1, mixing and stirring acrylic acid, higher alcohols and sulfonic acid catalysts to react to obtain acrylate;

[0024] Step 2: Add acrylate to the reaction vessel, raise the temperature in a water bath to T75°C-85°C, then add the initiator, and keep the constant temperature reaction time at T for t9h-11h to obtain the diesel pour point depressant solution;

[0025] Step 3, crystallizing the diesel pour point depressant solution, suction filtering, and vacuum drying to obtain the finished diesel pour point depressant.

[0026] The specific operation steps of step 1 are: add acrylic acid, C8-C18 monohydric alcohol, diesel oil, catalyst and polymerization inhibitor into a three-necked flask with an electric stirrer in sequence, heat up to the reflux temperature of 80°C under stirring, and maintain the reflux reaction for 10h, When the amount of water generated by the separatio...

Embodiment 2

[0036] Same as Example 1, the difference is:

[0037] The mass percent of acrylic acid is 70%, the mass percent of C8~C18 monohydric alcohol is 20%, the mass percent of p-benzenesulfonic acid is 3%, the mass percent of hydroquinone is 1%, the mass percent of azobisisobutyronitrile The percentage is 3%.

Embodiment 3

[0039] Same as Example 1, the difference is:

[0040] The mass percentage of acrylic acid is 80%, the mass percentage of C8~C18 monohydric alcohol is 15%, the mass percentage of p-benzenesulfonic acid is 2%, the mass percentage of hydroquinone is 0.75%, the mass percentage of azobisisobutyronitrile The percentage is 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com