Comprehensive utilization method of lignocellulose biomass

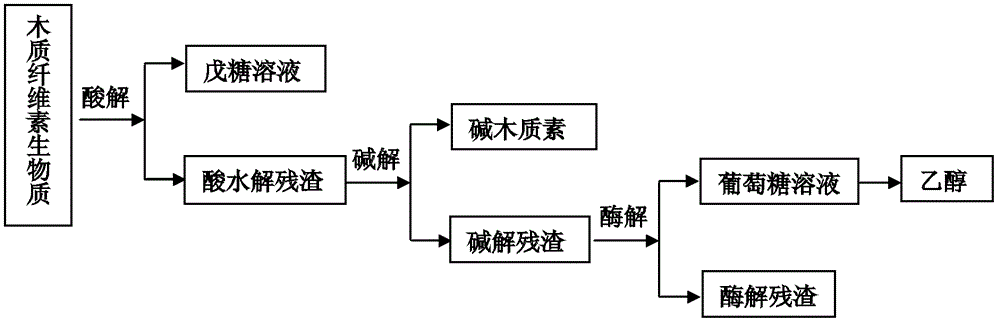

A technology of lignocellulose and biomass, which is applied in the field of comprehensive utilization of cellulose, hemicellulose and lignin in lignocellulosic biomass, can solve the problems of low conversion rate of cellulose enzymatic hydrolysis, and achieve improved extraction rate and equipment Simple maintenance and the effect of eliminating space obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) acid hydrolysis

[0047] 10.6kg corn cobs (mass composition: moisture 6.12%, cellulose 35.19%, hemicellulose 32.1%, lignin 23.7%, other 2.95%, the same below) are broken, washed with water to remove dust, and then processed with 80kg phosphoric acid solution Hydrolysis, the mass concentration of phosphoric acid solution is 15%, the temperature of acid hydrolysis is 140 ℃, the time is 0.5 hour, the acid hydrolysis residue and the pentose sugar solution obtained after hydrolysis are separated, wash described acid hydrolysis residue with 10kg water, cleaning solution Merge with described pentose solution, finally obtain 17.9kg acid hydrolysis residue (moisture content is about 65%, the absolute dry content of hemicellulose is 13.03%, the absolute dry content of lignin is 32.67%, the absolute dry content of cellulose 49.27%) and 82.07kg pentose solution, the concentration of pentose solution is 3.16%. Then the extraction rate of hemicellulose is 76%.

[0048] The calc...

Embodiment 2

[0060] (1) acid hydrolysis

[0061] Break 10.6kg of corncobs, wash with water to remove dust, and then hydrolyze with 80kg of phosphoric acid solution, the mass concentration of phosphoric acid solution is 20%, the temperature of acid hydrolysis is 100°C, and the time is 2 hours. After the hydrolysis is completed, the separated acid hydrolysis Residue and pentose solution, wash described acid hydrolysis residue with 10kg water, and cleaning solution merges with described pentose solution, finally obtain 16.42kg acid hydrolysis residue (moisture content is about 65%, and the absolute dry content of hemicellulose is 11.86 %, the absolute dry content of lignin is 32.72%, the absolute dry content of cellulose is 49.95%) and 83.56kg pentose sugar solution, and the concentration of pentose sugar solution is 3.26%. Then the extraction rate of hemicellulose is 80%.

[0062] (2) Extraction of alkali lignin with alkaline solution

[0063] Mix all acid hydrolysis residues obtained in s...

Embodiment 3

[0067] (1) acid hydrolysis

[0068] Break 10.6kg of corncobs, wash with water to remove dust, and then use 80kg of phosphoric acid solution for hydrolysis, the mass concentration of phosphoric acid solution is 5%, the temperature of acid hydrolysis is 150 ° C, and the time is 3 hours. Residue and pentose solution, clean described acid hydrolysis residue with 10kg water, and cleaning solution merges with described pentose solution, finally obtains 18.01kg acid hydrolysis residue (water content is about 65%, and the dry content of hemicellulose is 13.52 %, the dry content of lignin is 32.495%, the dry content of cellulose is 49%) and 81.98kg pentose solution, and the concentration of pentose solution is 3.12%. Then the extraction rate of hemicellulose is 75%.

[0069] (2) Extraction of alkali lignin with alkaline solution

[0070] All acid hydrolysis residues obtained in step (1) of this embodiment were processed according to the process method of step (2) of embodiment 1. Ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com