Novel transmission mechanism for single-cylinder engine

A technology of transmission mechanism and single-cylinder engine, applied in the field of gear transmission, can solve the problems of poor mechanism adjustment ability, high exhaust gas pressure of the whole machine, easy splashing of oil, etc., so as to reduce the height of the whole machine, improve the utilization rate, and avoid oil splashing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

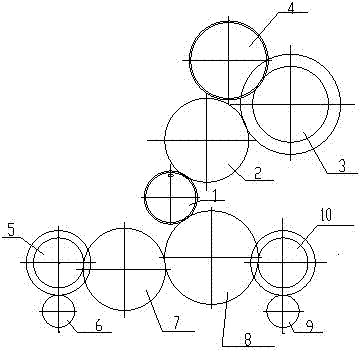

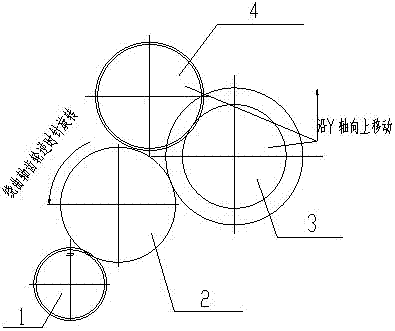

[0010] Such as figure 1 As shown, a new single-cylinder engine transmission mechanism, the fixed crankshaft gear 1 transmits the torque to the fixed high-pressure pump gear train 3 and the fixed gas distribution gear train 4 through the first idler gear 2 upwards, and the fixed crankshaft gear 1 passes through the second idler gear train downwards. The idler gear 8 and the third idler gear 7 transmit the torque to the second balance gear train 5, the second balance gear train 6, the first balance gear train 10, and the first balance gear train 9 to realize the fuel of the single-cylinder engine and the valve cam The shaft rotates, and the balance gear train drives the balance shaft to rotate to eliminate the unbalance of the whole machine.

[0011] Wherein the high-pressure pump gear train 3 is composed of two separate gears. The first balance gear train 10 and the second balance gear train 5 are combined by 4 gears to form a pinch wheel structure which is a first-order balan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com