Analysis method for polyether polyol hydroxyl value

A technology of polyether polyol and analysis method, which is applied in the direction of material analysis through observation of the influence of chemical indicators, and analysis through chemical reaction of materials, etc., which can solve the problems of complex analysis steps, long detection cycle, and high cost , to achieve the effect of simple analysis steps, reduced experiment cost and good accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the protection scope of the present invention can be more clearly defined.

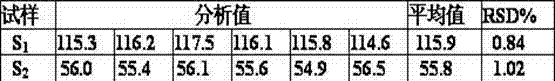

[0024] This embodiment respectively carries out 6 times of hydroxyl value analysis to two groups of samples S1 and S2 according to the following steps:

[0025] A. Weigh the sample m of polyether polyol in a 250ml ground conical flask, and take another empty conical flask;

[0026] B. Pipette 25ml of the pyridine solution of phthalic anhydride into the conical flask and the empty conical flask containing the sample respectively, and place the two conical flasks in a shaking oil bath at 120±3°C, then connect the Put on a 30mm air condenser and react for 1 hour;

[0027] C, until the end of the reaction, the two conical flasks are taken out from the oil bath, and placed in a room tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com