Simple and easy preparation method of ultra-micro electrode

An ultra-micro electrode and simple technology, applied in the field of electrochemistry, can solve the problems of decreased success rate, inability to use, and poor sealing of electrodes, and achieve the effect of high success rate and simple production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

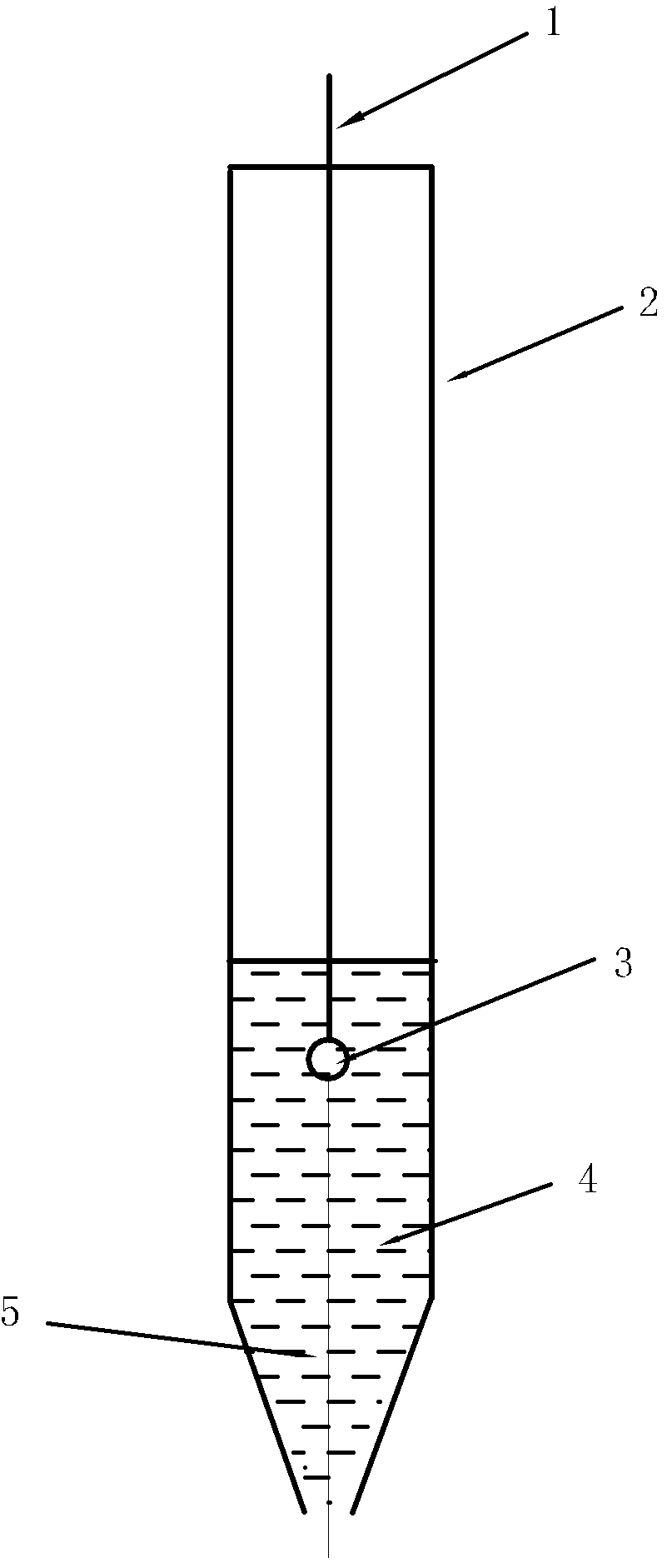

[0018] as attached figure 1 As shown, 1 is a current collector, 2 is a glass capillary, 3 is a conductive glue, 4 is an epoxy resin, and 5 is an electrode fiber. The simple preparation method of a kind of ultra-micro electrode of the present invention includes: connecting the electrode fiber and the current collector steps, removing impurities from electrode fibers, preparing epoxy resin, fixing electrode fibers with epoxy resin, and cleaning electrode fibers;

[0019] The steps of the simple preparation method of the described ultramicroelectrode are as follows: prepare a stable metal wire as a current collector, prepare an electrode fiber, and the electrode fiber material has the following characteristics: it is difficult to implement through the traditional heat-sealing preparation method Electrode materials, including combustible materials such as carbon fiber materials, easily meltable materials such as gold fiber materials, easily oxidizable materials such as nickel fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com