Pipe excitation source identification and prediction method of vibration response to pipe excitation source

A technology of vibration response and prediction method, which is applied in the field of vibration reduction and noise reduction, can solve problems such as complex identification procedures, and achieve the effects of high prediction accuracy, simple prediction device, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in more detail below in conjunction with accompanying drawing example:

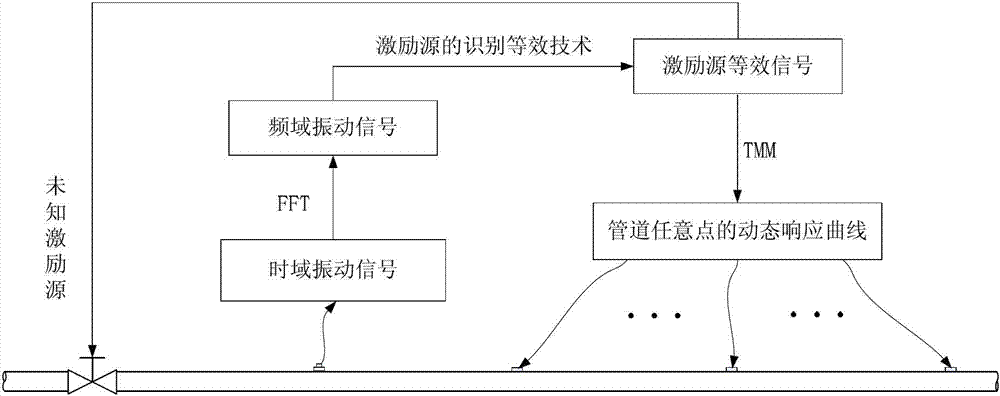

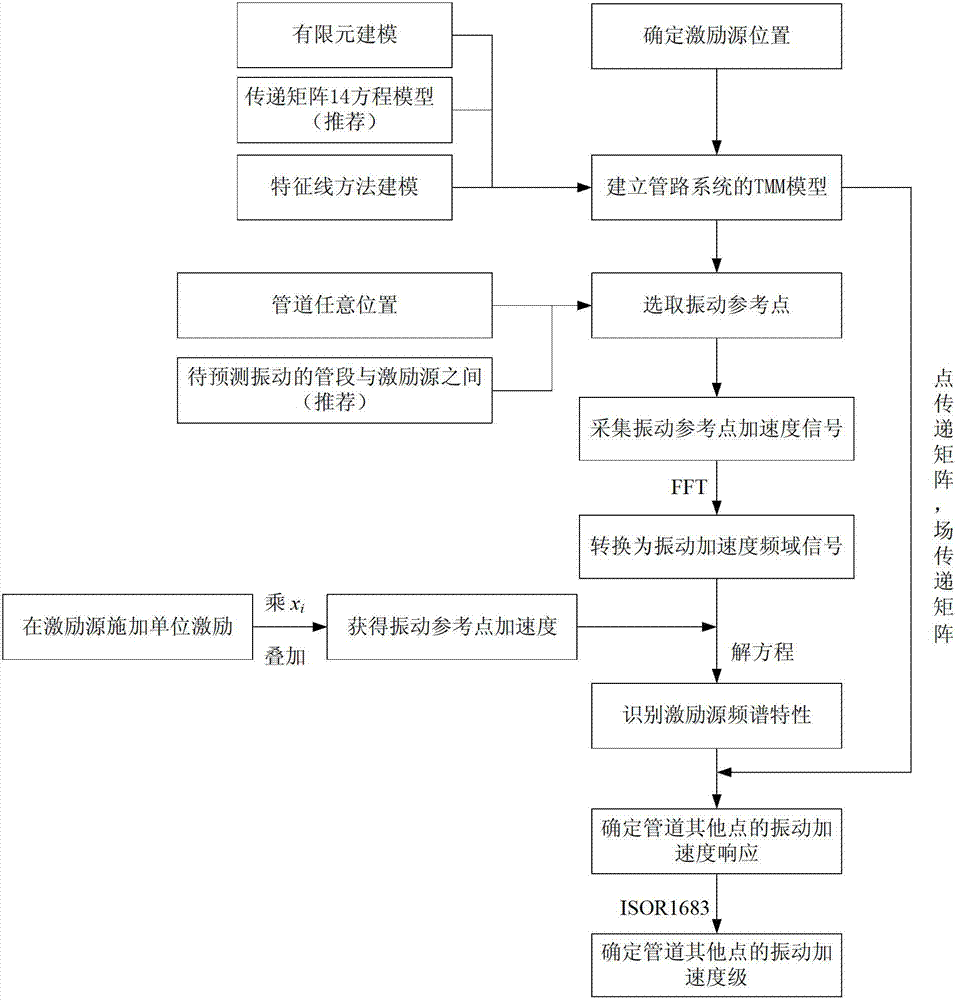

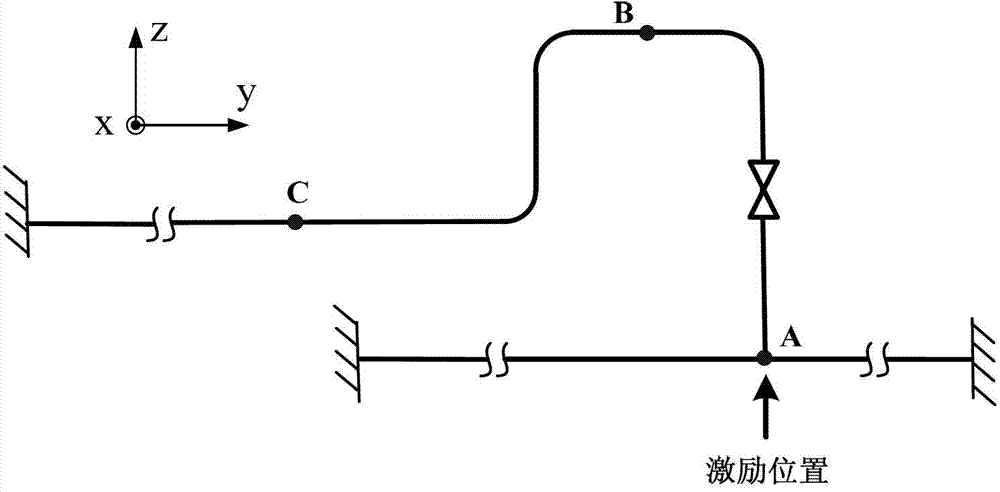

[0034] combine Figure 1~3 , the excitation source identification and vibration prediction method of the present invention comprises the following steps:

[0035] (1) Determine the position of the equivalent excitation source of the pipeline, and establish the frequency domain transfer matrix (TMM) model of the pipeline system (D tot ).

[0036] First, according to the arrangement of excitation sources such as valves, branch pipes and elbows in the pipeline system, determine the location and number n of excitation sources, and assume that the size of the i-th excitation source is equal to x i (i=1,2,...n). Then according to the motion equation of the piping system, the TMM model of the piping system is established.

[0037] as attached figure 2 As shown, in addition to the TMM model of the pipeline system, the finite element (FEM) model and the characteristi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com