Power source power off maintaining circuit

A technology for maintaining circuit and power failure, applied in the field of avionics, can solve the problems of electronic equipment cost, volume, weight increase, the influence of capacitor storage energy, uncontrollable power failure maintenance time, etc., to achieve power failure maintenance time control, easy integration and modular production, and the effect of easy integration and modular production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing the present invention is described in further detail, please refer to Figure 1 to Figure 3 .

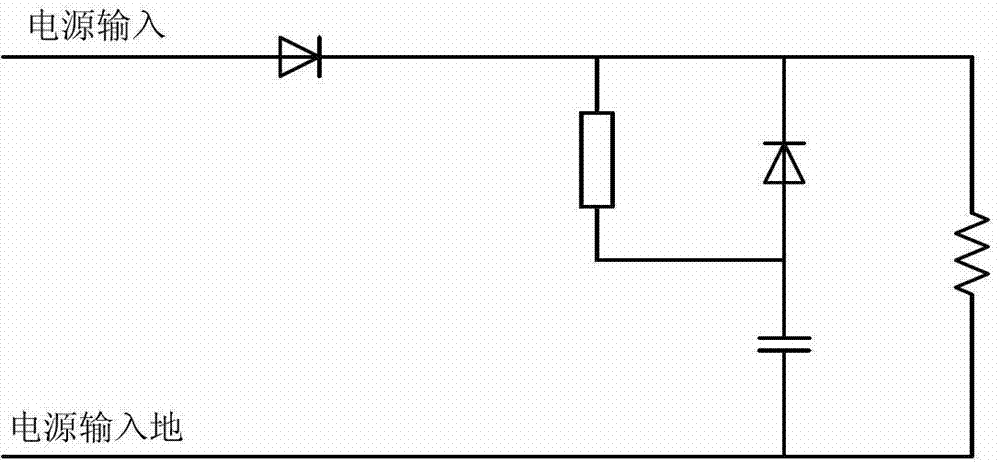

[0025] Such as figure 1 As shown, it is a traditional power supply maintenance circuit. The traditional power supply maintenance circuit is designed with a large-capacity energy storage capacitor, a current limiting resistor, a discharge diode, and an anti-capacitor power recharge diode. The basic principle is to use the energy storage of the capacitor characteristics, to achieve the purpose of capacitor discharge when the power supply is cut off, so as to maintain the continuous operation of electronic equipment.

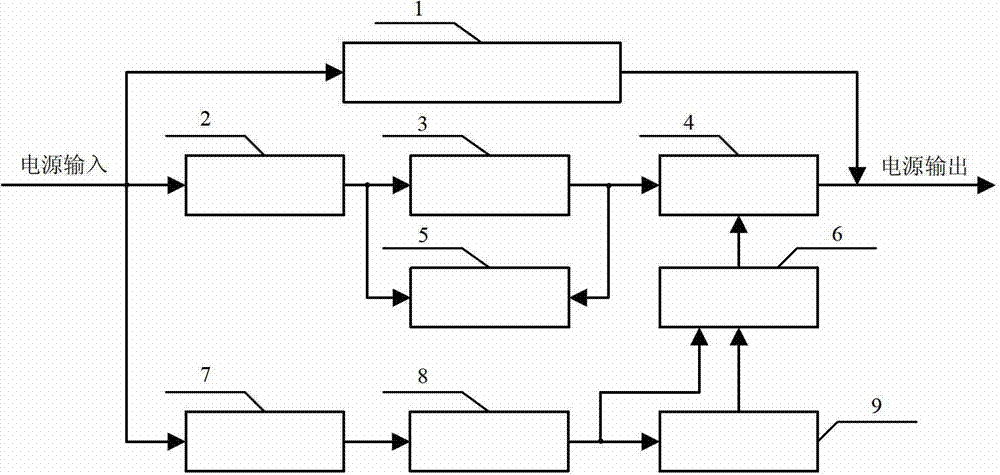

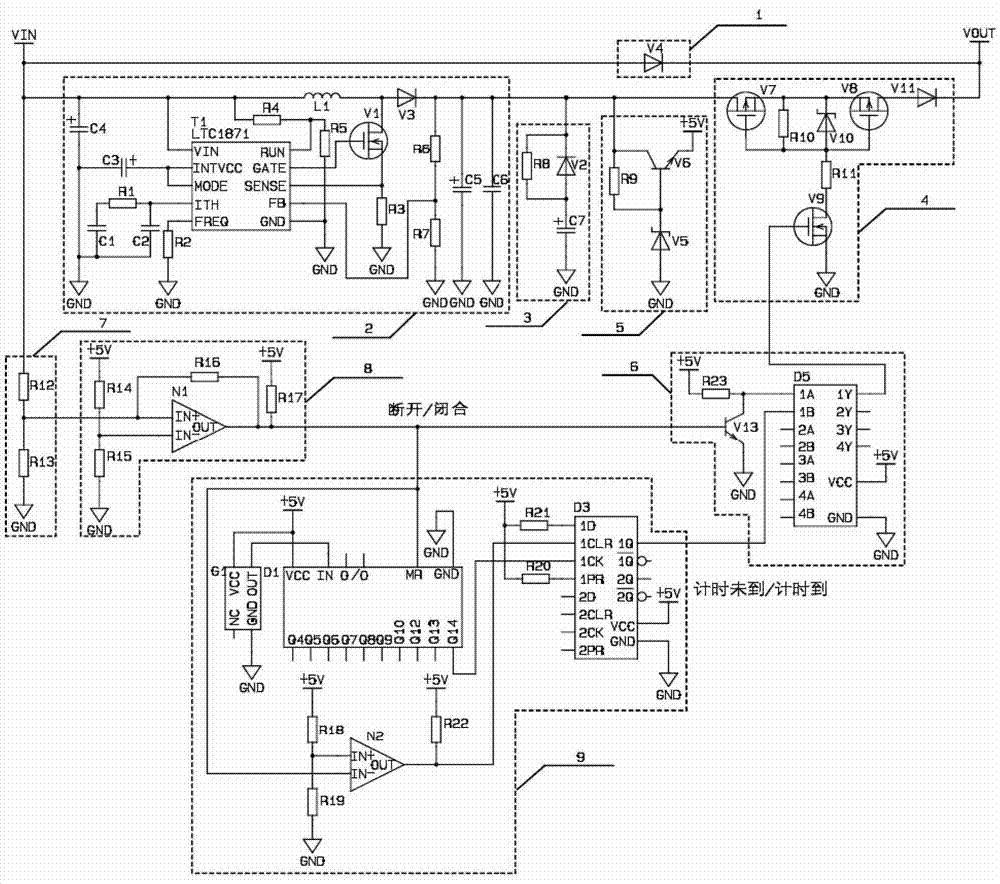

[0026] Such as figure 2 and image 3 Shown is the schematic block diagram and circuit diagram of the circuit of the present invention, a power supply maintenance circuit, including a main power supply input channel circuit 1, a boost circuit 2, and an energy storage capacitor charging circuit 3 between the power s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com