Ultrafine dry powder extinguishing method for high-rack stereoscopic warehouse

A technology of ultra-fine dry powder and three-dimensional storage, which is applied in fire rescue and other fields, and can solve problems such as the inability to ensure that protective materials will not be affected by water stains, the lack of fire-fighting methods for elevated three-dimensional warehouses, and the impact of special-shaped devices on fire-extinguishing capabilities, and achieve a simple and practical structure. , short fire extinguishing time and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

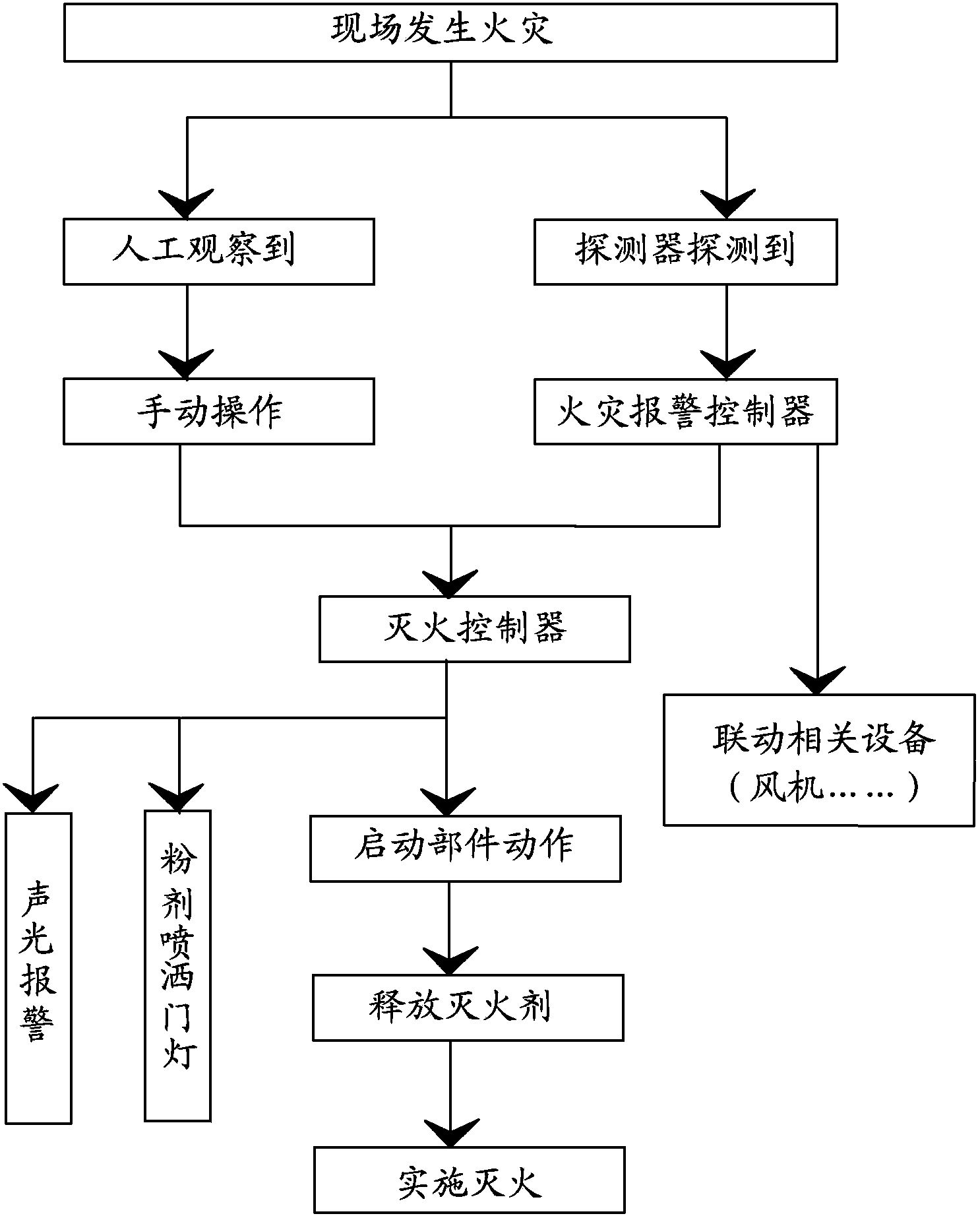

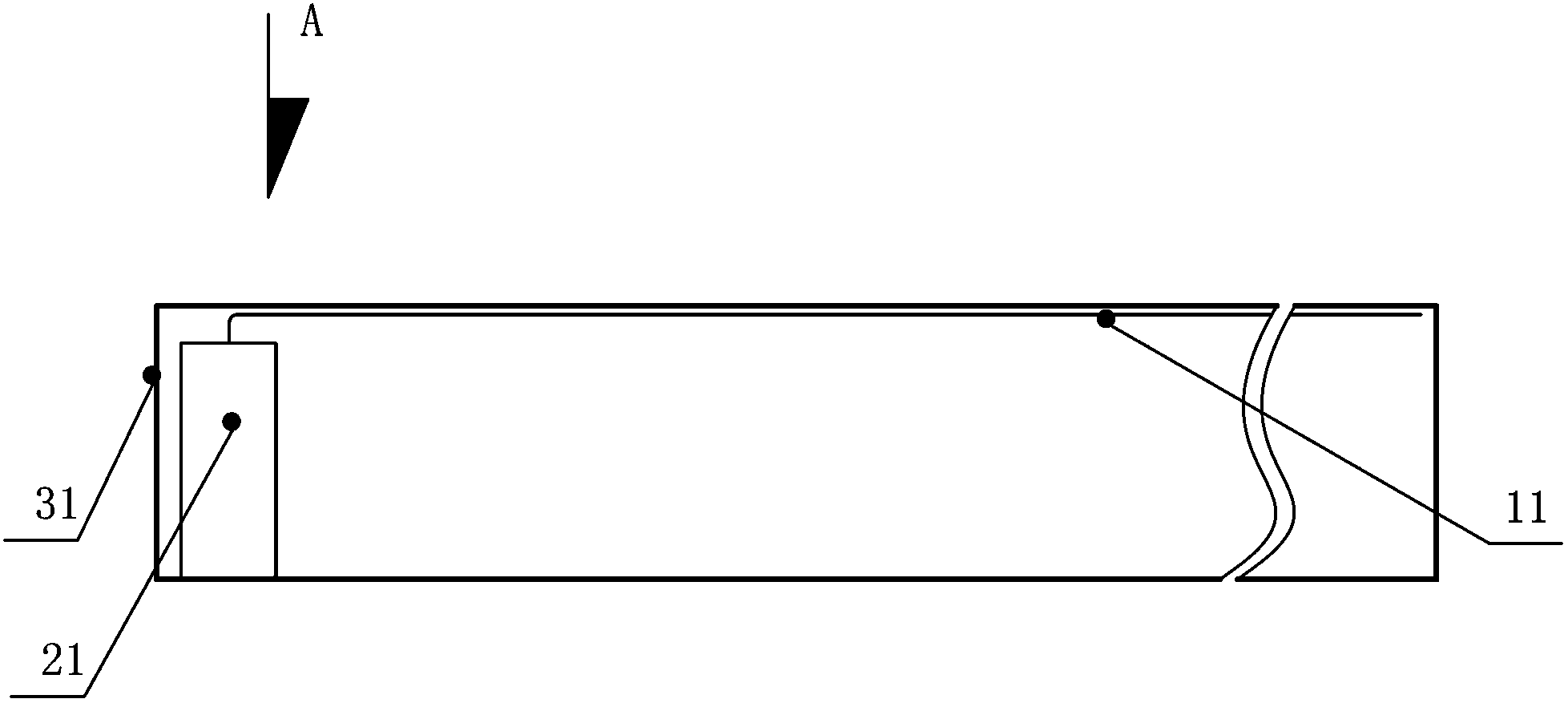

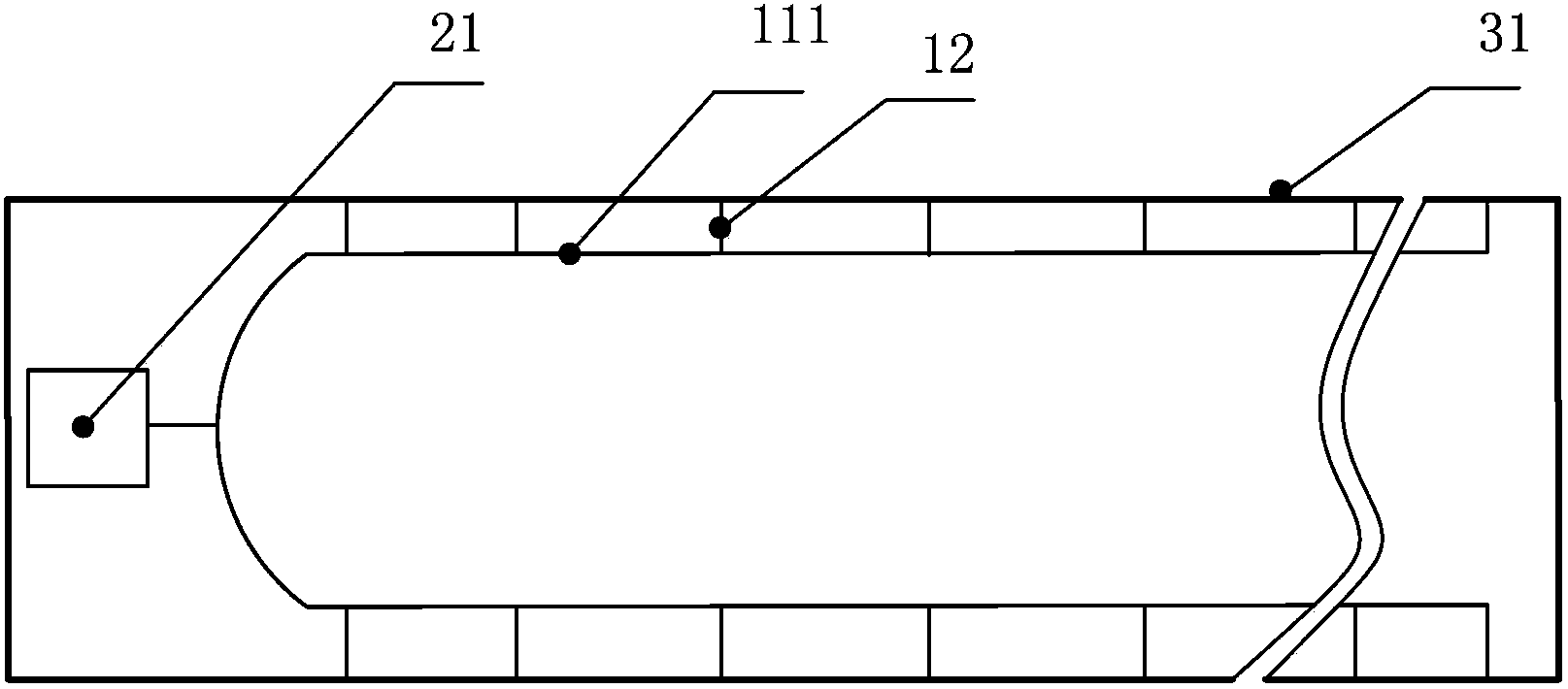

[0061] A communications equipment warehouse of the People’s Liberation Army is 95m long, 32.4m wide, and 22m high. There are 14 rows of shelves inside, one row of single-row shelves on each side, and six rows of back-to-back shelves in the middle. Each row is 76.8m long, 1.1m wide, and 20.45m high. Each row of shelves is divided into 11 layers, the height of the bottom two layers of shelves is 1.875m, the height of the remaining nine layers is 1.575m, and the length of each shelf is 2.4m.

[0062] According to the method described in the present invention, each row of shelves is used as a fire extinguishing partition, and a total of 14 fire protection partitions are established; each row of shelves is separated from the middle position, and every three floors are used as a fire extinguishing unit module, which is divided into six fire extinguishing unit modules. The unit module is equipped with a set of gas-powder mixed fire extinguishing device with a filling pressure of 1.4MP...

Embodiment 2

[0066] Example 2 An electronic product logistics warehouse is 106.9m long, 53.4m wide, and 14.5m high. There are 40 rows of shelves inside, each row is 43.2m long, 1.1m wide, and 11.8m high. Each row of shelves is divided into 7 floors. The height of the shelves on the third floor is 1.8m, and the height of the other four floors is 1.6m. All of them are back-to-back shelves. The distance between the shelves is 0.25m, and the width of the forklift aisle is 1.72m. Each compartment is 2.4m long.

[0067] According to the method of the present invention, each row of shelves is used as a fire extinguishing partition, and there are 40 fire protection partitions in total; the lower three floors of each row of shelves are used as a fire extinguishing unit, and the upper four floors are used as a fire extinguishing unit, and a fire extinguishing unit is equipped with a set of gas storage Bottle-type fire extinguishing device, two sets of ultra-fine dry powder fire extinguishing devices...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com