Three-dimensional laser washing device

A cleaning device, laser three-dimensional technology, applied in the field of laser cleaning, to achieve the effect of simple structure, good stability, and easy debugging

Inactive Publication Date: 2013-04-24

JIANGSU UNIV

View PDF7 Cites 42 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in practical applications, the surface of the material to be cleaned is not a plane in many cases, but has a certain changing curve. Therefore, this two-dimensional optical scanning galvanometer cannot fully meet the actual needs. It is necessary to scan the laser on the two-dimensional galvanometer. Design a three-dimensional scanning laser cleaning device based on the cleaning device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

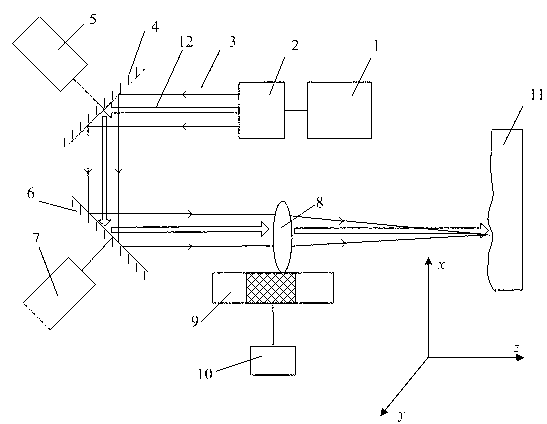

[0018] Using 1064nm solid-state laser with a frequency of 5Hz, SamLight two-dimensional optical scanning galvanometer and 254nm focal length cleaning, the filter only allows 632.8nm light to pass through, and the imaging lens is also selected to be 254nm, θ=15°, using industrial area array CCD to collect images .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

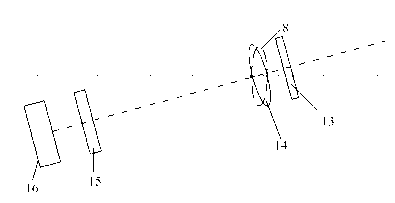

The utility model discloses a three-dimensional laser washing device. The three-dimensional laser washing device comprises a pulsed laser with indicating red light and a control system of the same pulsed laser, a beam spread collimation optical system, a two-dimensional optical scanning galvanometer and a controller of the same two-dimensional optical scanning galvanometer, a focusing position regulator and a displacement controller. The focusing position regulator consists of a focusing lens, a filter, a microscopic imaging lens, a CCD (Charge Coupled Device) and a processor, wherein the focusing lens is fixed with the microscopic imaging lens, the indicating red light of the pulsed laser reflects on the sample and images on the CCD (Charge Coupled Device), the microscopic imaging lens moves longitudinally to find a position where the contrast ratio is the highest and the image edge is the clearest, the position is a focus position of the focusing lens, and the three-dimensional laser washing device consists of the two-dimensional scanning galvanometer and the focusing lens. The three-dimensional laser washing device makes full use of the two-dimensional laser washing device which is based on the optical galvanometer scanning system, presetting the surface shape of the washing material is not required before cleaning, thereby having the advantages of being wide in application, simple in structure, good in stability, easy to debug, and the like.

Description

technical field [0001] The invention belongs to the field of laser cleaning, and in particular relates to a three-dimensional laser cleaning device based on an optical two-dimensional scanning vibrating mirror and which can be automatically adjusted according to the surface shape of a material to be cleaned. technical background [0002] Laser cleaning is a new type of green cleaning method, which can clean various types of pollutants on the surface of various materials. It has the advantages of convenient long-distance and automatic operation. At present, laser cleaning devices are basically aimed at planar structures, using optical galvanometer scanning systems to achieve two-dimensional cleaning. The working principle of the optical galvanometer scanning system is to collimate the laser output from the laser and then control the movement in the x-axis and y-axis directions by two scanning galvanometers, and then converge to the material surface by the focusing lens. This...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K26/04B08B7/00B23K26/046

Inventor 佟艳群沈全邵祥松宣婷张罗王浩

Owner JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com