Vacuum pressure swing adsorption oxygen generation system and control method thereof

A vacuum pressure swing adsorption and control method technology, which is applied in separation methods, chemical instruments and methods, oxygen preparation, etc., can solve the problems of reducing oxygen recovery rate, waste of product body, loss of product gas, etc., so as to improve utilization efficiency and improve The effect of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

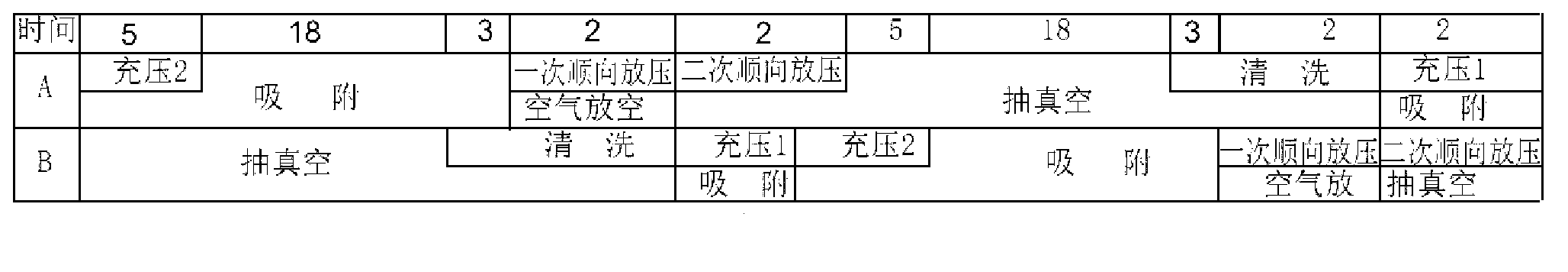

Embodiment 1

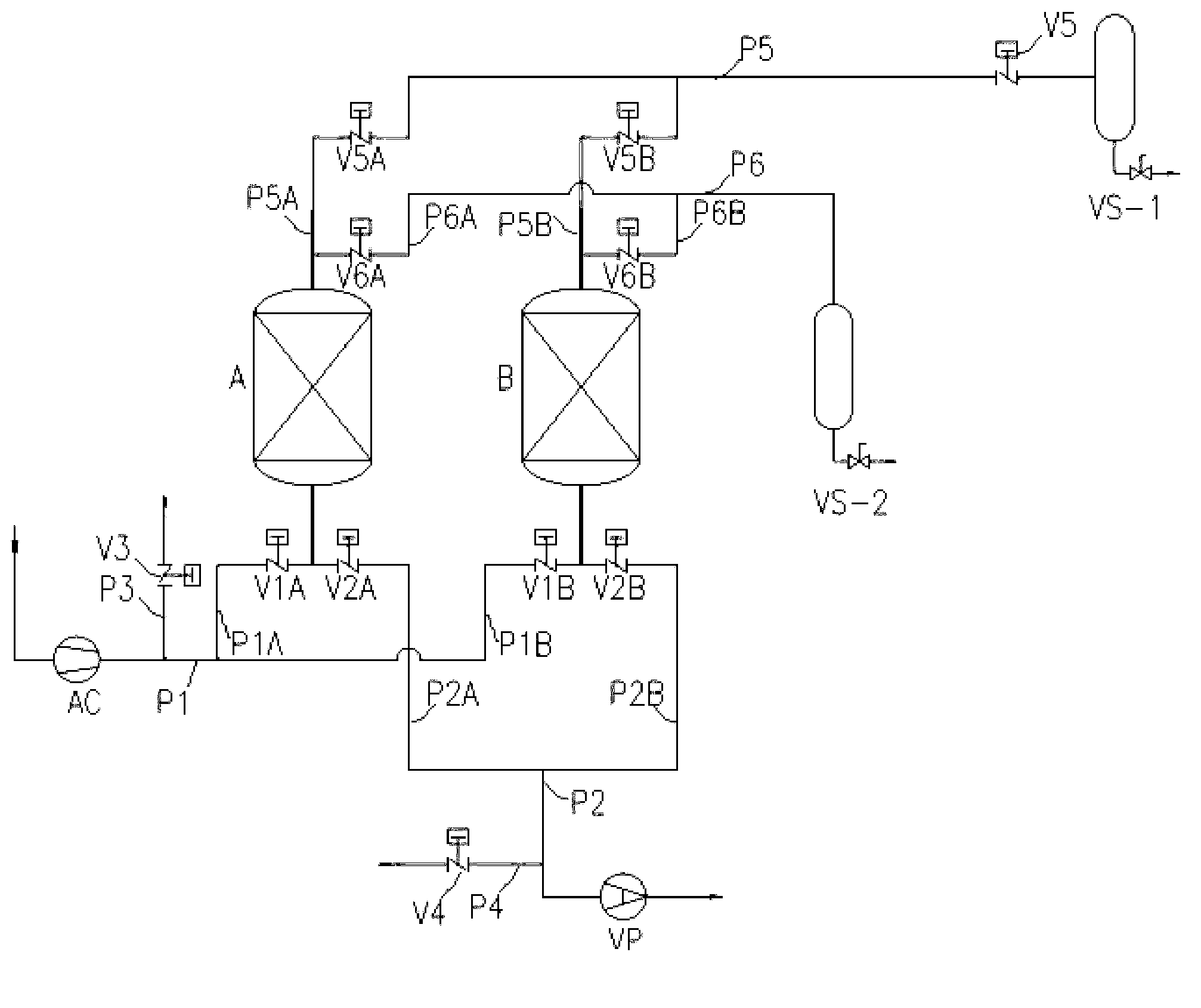

[0036] The vacuum pressure swing adsorption oxygen generating device in this embodiment includes: a first adsorber A, a second adsorber B, a blower AC, a vacuum pump VP, a buffer tank VS-1 and a first pressure equalization tank VS-2; wherein,

[0037] The blower AC is connected to the inlet ports of the first adsorber A and the second adsorber B respectively through the air main pipe P1, the first air branch pipe P1A and the first air branch pipe P1B;

[0038] The blower AC is also communicated with the atmosphere through the first vent pipe P3;

[0039] The vacuum pump VP is connected to the inlet ports of the first adsorber A and the second adsorber B respectively through the vacuum main pipe P2, the first vacuum branch pipe P2A and the second vacuum branch pipe P2B;

[0040] The vacuum pump VP is also communicated with the atmosphere through the second vent pipe P4;

[0041] The outlet ports of the first adsorber A and the second adsorber B are respectively connected to th...

Embodiment 2

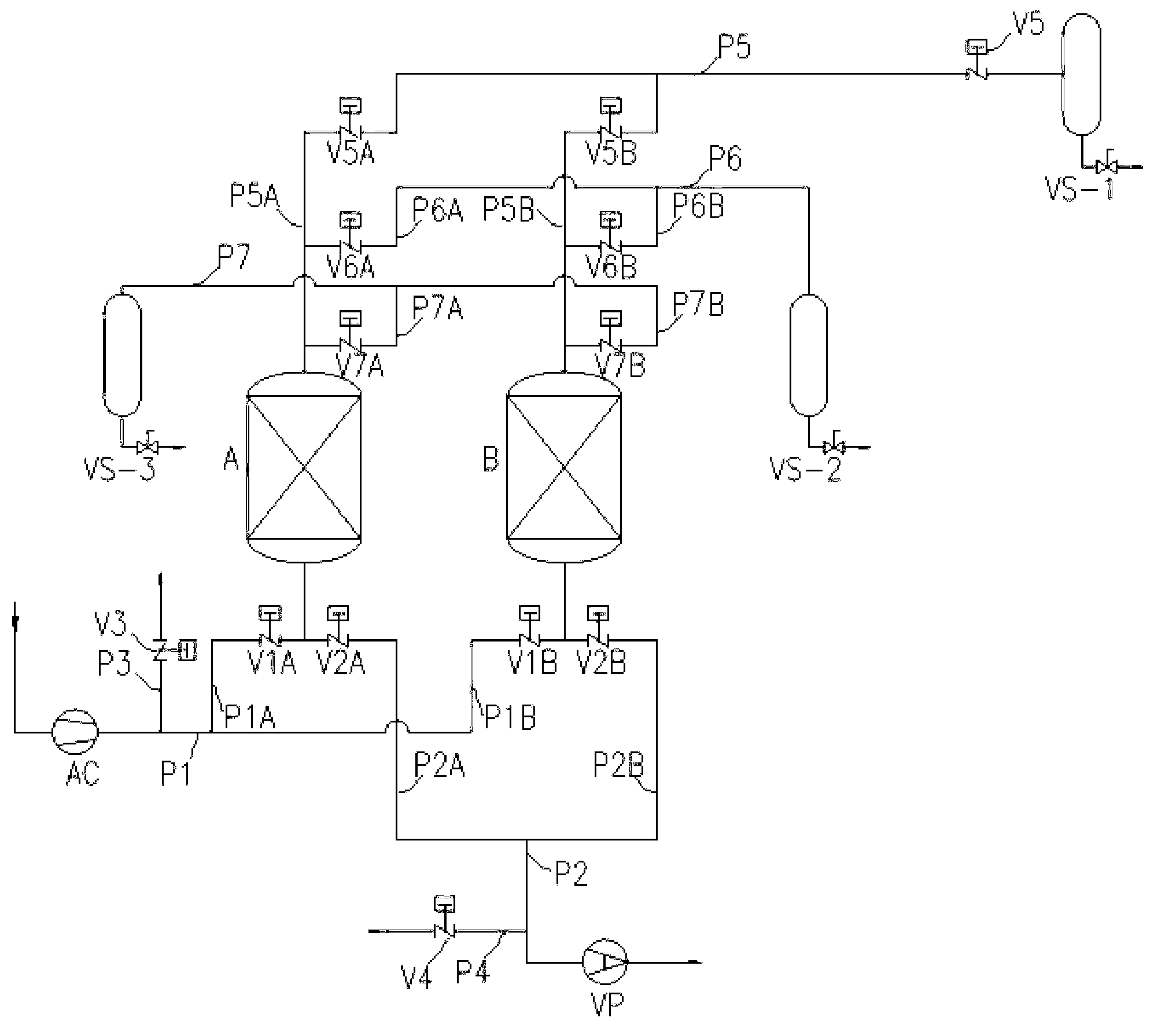

[0051] The vacuum pressure swing adsorption oxygen generating device in this embodiment includes: a first adsorber A, a second adsorber B, a blower AC, a vacuum pump VP, a buffer tank VS-1, a first equalizing tank VS-2 and a second equalizing tank Pressure tank VS-3; among them,

[0052] The blower AC is connected to the inlet ports of the first adsorber A and the second adsorber B respectively through the air main pipe P1, the first air branch pipe P1A and the first air branch pipe P1B;

[0053] The blower AC is also communicated with the atmosphere through the first vent pipe P3;

[0054] The vacuum pump VP is connected to the inlet ports of the first adsorber A and the second adsorber B respectively through the vacuum main pipe P2, the first vacuum branch pipe P2A and the second vacuum branch pipe P2B;

[0055] The vacuum pump VP is also communicated with the atmosphere through the second vent pipe P4;

[0056] The outlet ports of the first adsorber A and the second adsor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com