Method for reducing content of ammonia nitrogen in urea process condensate

A technology of ammonia nitrogen content and condensate, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, degassed water/sewage treatment, etc. The effect of system water balance optimization and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

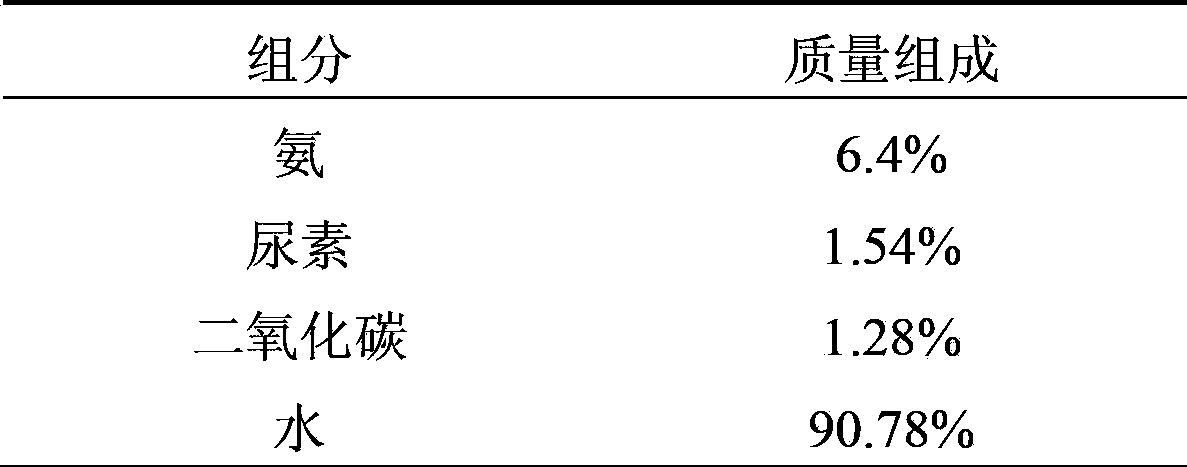

[0028] Embodiment 1, use the method of the present invention to process urea process condensate

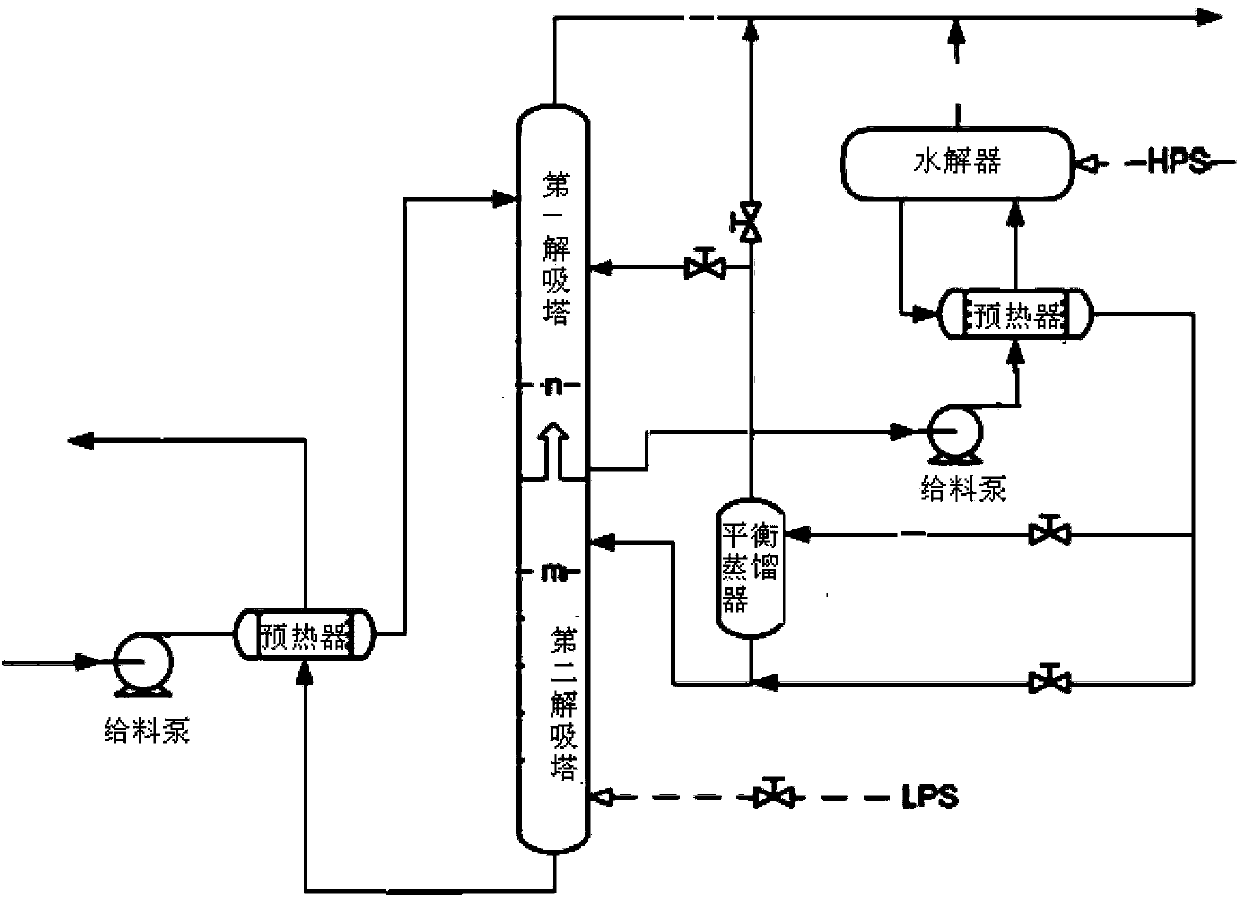

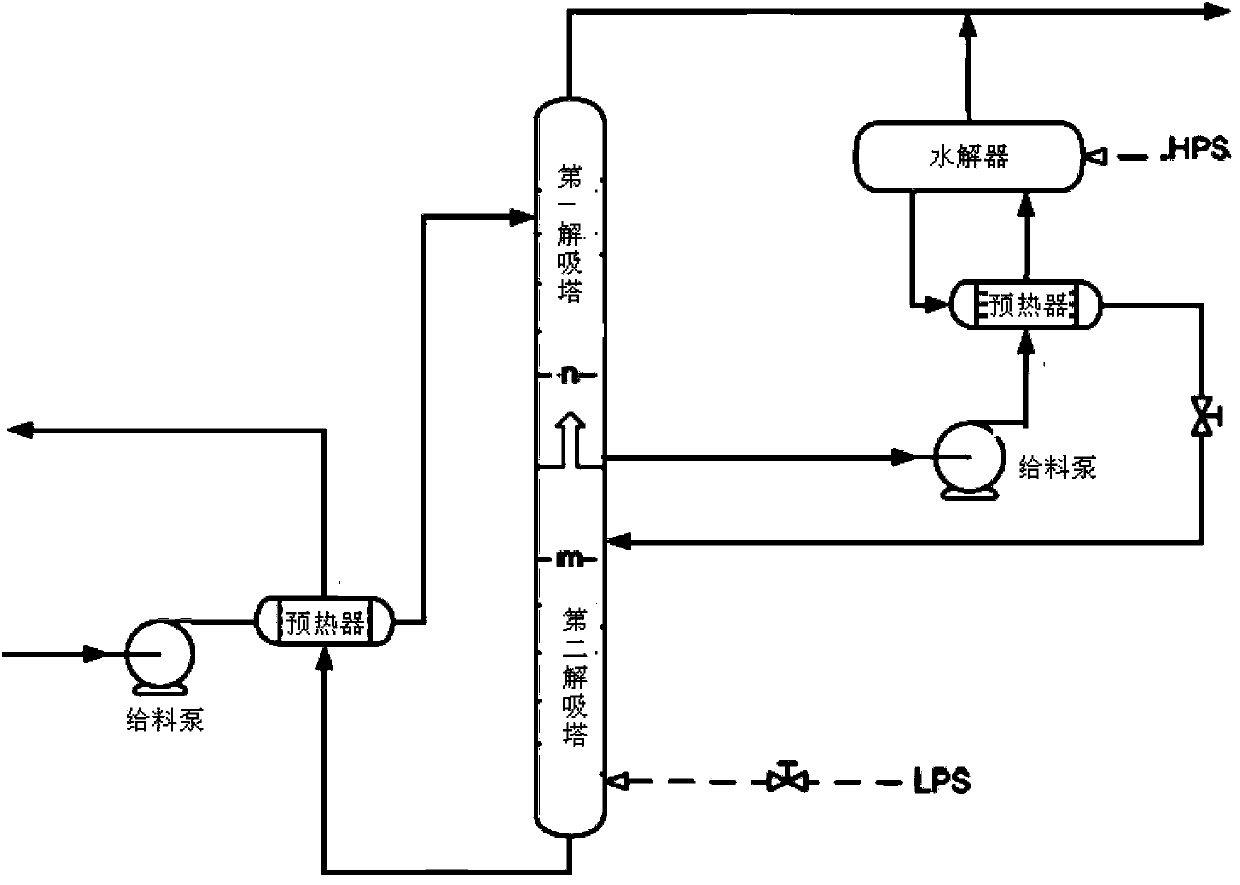

[0029] The process flow chart of present embodiment processing is as figure 1 shown.

[0030] (1) The above-mentioned urea process condensate is sent to the horizontal hydrolyzer after the first-stage desorption pretreatment on the upper part of the upper tower of the desorption tower, where it is completed by injecting high-pressure steam (4.3Mpa, 387°C) Urea hydrolysis reaction, wherein the operating pressure of the hydrolyzer is controlled to be 3.43Mpa, the temperature is 232°C, and the residence time in the hydrolyzer is 30 minutes.

[0031] (2) The liquid phase in the hydrolyzer enters two series-connected equilibrium stills for equilibrium distillation, and the pressures of the equilibrium distillation are 0.64Mpa and 0.52Mpa respectively. The gas phase generated during the equilibrium distillation process is reinjected into the upper section of the upper column of the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com