Praziquantel preparation process

A production process and technology of praziquantel, which is applied in the field of preparation of synthetic praziquantel intermediates, can solve the problems of a large amount of halogen-containing organic solvents, complex process operation, and high energy consumption, and achieve improved yield and purity, and process operation Simple, waste reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

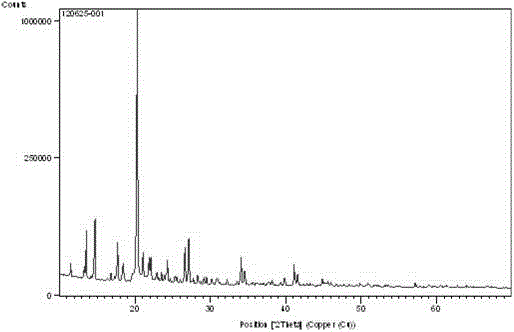

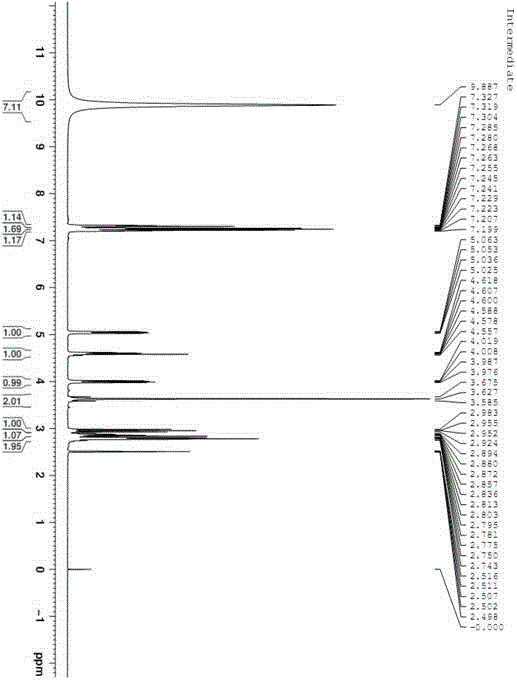

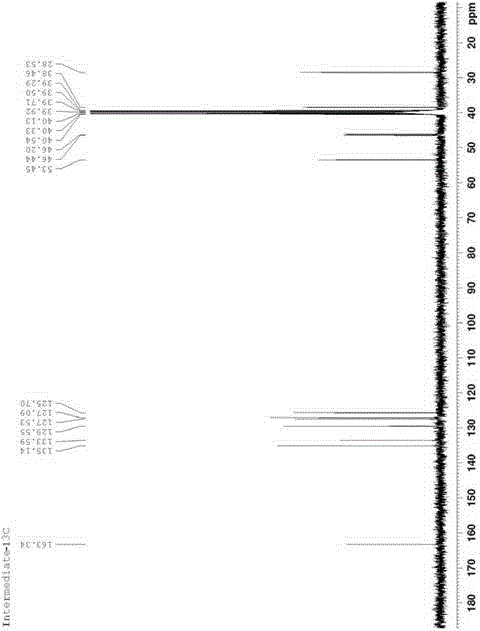

Image

Examples

Embodiment 1

[0034] Embodiment 1: The preparation method of a kind of praziquantel of the present embodiment is carried out according to the following steps:

[0035] (1) Add 136 g of 85% phosphoric acid and 120 g of compound I in sequence to a 500 mL three-neck flask equipped with a reflux condenser, a thermometer, and a magnetic stirring device, and turn on mechanical stirring for about ten minutes. Turn on the condensate, turn off the mechanical stirring, and turn on the heating to 150°C. After 2 hours of heat preservation, turn on mechanical stirring and continue heat preservation for 5 hours;

[0036] (2), change reaction device into decompression device, open vacuum pump; Under heat preservation, decompression removes the benzoic acid that reaction generates, and pressure is at 5-20mbar, collects benzoic acid 40g. Slowly add 85 g of deionized water at 80°C to the reaction solution, reflux for 30 minutes, turn off the heating, cool down to room temperature, cool to 0°C and continue s...

Embodiment 2

[0048] Embodiment 2: the preparation method of a kind of praziquantel of the present embodiment, other steps are identical with embodiment 1, just the phosphoric acid consumption of step 1 and the deionized water consumption of step 2 are as follows:

[0049] In a 500mL three-neck flask equipped with a reflux condenser, a thermometer, and a magnetic stirring device, add 400g of 85% phosphoric acid and 120g of compound I in sequence, and start mechanical stirring for about ten minutes. Turn on the condensate, turn off the mechanical stirring, and turn on the heating to 150°C. After 2 hours of heat preservation, turn on mechanical stirring and continue heat preservation for 5 hours. After removing benzoic acid under reduced pressure, 200 g of deionized water at 80° C. was slowly added to the reaction liquid. 103 g of crude praziquantel was prepared, and 83 g of praziquantel was obtained by recrystallization.

Embodiment 3

[0050] Embodiment 3: the preparation method of a kind of praziquantel of the present embodiment, other steps are identical with embodiment 1, just the phosphoric acid consumption of step 1 and the deionized water consumption of step 2 are as follows:

[0051] In a 500mL three-neck flask equipped with a reflux condenser, a thermometer, and a magnetic stirring device, add 220g of 85% phosphoric acid and 120g of compound I in sequence, and start mechanical stirring for about ten minutes. Turn on the condensate, turn off the mechanical stirring, and turn on the heating to 150°C. After 2 hours of heat preservation, turn on mechanical stirring and continue heat preservation for 5 hours. After removing benzoic acid under reduced pressure, 200 g of deionized water at 80° C. was slowly added to the reaction liquid. 100 g of crude praziquantel was prepared, and 80 g of praziquantel was obtained by recrystallization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com