Polymerizable organic strong acid / sulfuric acid composite curing agent and foamable phenolic resin combination thereof

A technology of composite curing agent and strong organic acid, which is applied in the field of polymerizable organic strong acid/sulfuric acid composite curing agent and its foamable phenolic resin composition, can solve the problem of slow reaction, increased apparent density of phenolic foam, safety and thermal insulation. Performance reduction and other problems, to achieve the effect of fast foaming speed, low apparent density and low corrosiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

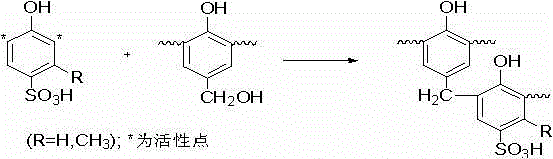

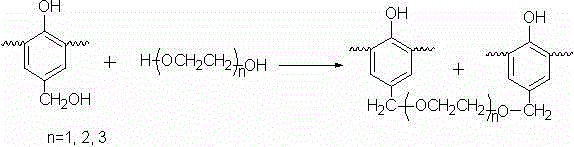

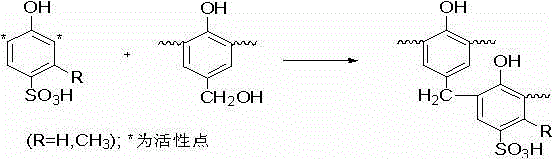

Method used

Image

Examples

Embodiment 1

[0039] 1. Add 141g of phenol into the reactor and preheat to 80°C; 165g (98%) concentrated sulfuric acid was slowly added to the reaction vessel within 1 hour under stirring, and continued to react for 3 hours after adding; Add 116g of ethylene glycol, stir evenly, then cool and discharge to obtain curing agent C-1.

[0040] 2. Weigh 90g of liquid resole phenolic resin, 2.7g of DC-193, 8.1g of methylene chloride, 7.2g of curing agent C-1 in a plastic beaker. In a 200*200*40 steel mould, put the mold into a 60-75°C oven to foam for 20 minutes, cool and demould, and obtain a uniform cell structure and an apparent density of 0.043g / cm 3 The high-quality phenolic foam has a closed cell rate greater than 92% and a pH value of 5.8.

Embodiment 2

[0042] 1. Add 141g of phenol into the reactor and preheat to 80°C; Slowly add 180g (98%) concentrated sulfuric acid to the reaction vessel under stirring within 1 hour, and continue to react for 3 hours after adding; Add 80g of diethylene glycol, stir evenly, then cool and discharge to obtain curing agent C-2.

[0043] 2. Weigh 90g of liquid resole phenolic resin, 2.7g of DC-193, 8.1g of methylene chloride, 6.3g of curing agent C-2 in a plastic beaker. In a 200*200*40 steel mould, put the mold into a 60-75°C oven to foam for 20 minutes, cool and demould, and obtain a uniform cell structure and an apparent density of 0.041g / cm 3 The high-quality phenolic foam has a closed cell rate of more than 92% and a pH value of 5.6.

Embodiment 3

[0045] 1. Add 162g m-cresol into the reactor and preheat to 80°C; 172.5g (98%) concentrated sulfuric acid was slowly added to the reaction vessel within 1 hour under stirring, and the reaction was continued for 3 hours after adding; Add 175 g of triethylene glycol compound, stir evenly, then cool and discharge to obtain curing agent C-3.

[0046] 2. Weigh 90g of liquid resole phenolic resin, 3.6g of Tween-80, 6.3g of n-pentane, 7.8g of curing agent C-3 in a plastic beaker. Put the mold into a 200*200*40 steel mould, put the mold into a 60-75°C oven for foaming for 20 minutes, cool and demould, and obtain a uniform cell structure and an apparent density of 0.045g / cm 3 The phenolic foam has a closed cell rate of 93% and a pH value of 5.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com