Hot vulcanization adhesive

A technology of adhesives and thermal vulcanization, which is applied in the direction of adhesives, halogen rubber derivative adhesives, adhesive types, etc., and can solve problems such as endangering workers' health and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The foregoing description and the following examples are intended to disclose and illustrate the present invention, and the specific amounts and combinations of the ingredients described herein are not intended to limit the scope of the present invention defined by the claims.

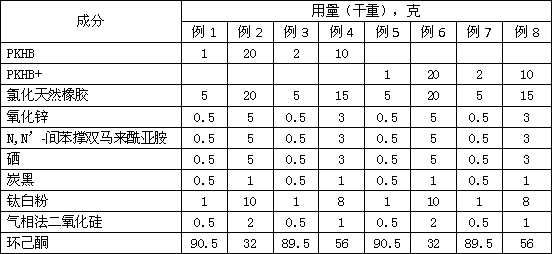

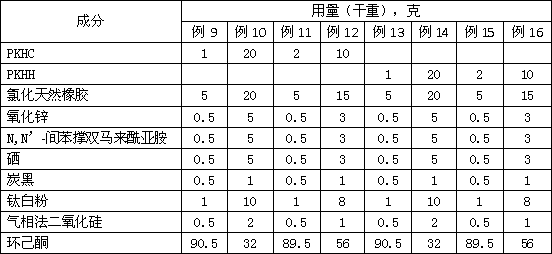

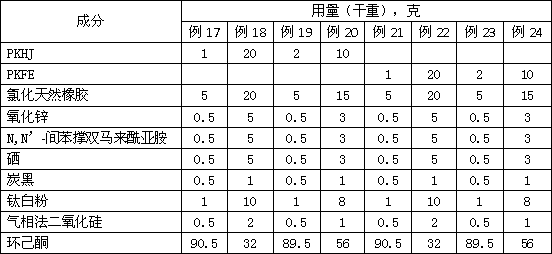

[0039] The heat vulcanizable adhesives of the present invention were prepared as follows:

[0040]

[0041]

[0042]

[0043]

[0044]

[0045] To prepare test specimens, grit-blasted steel sheets were degreased with perchlorethylene vapor and dried. The steel sheet is prepared according to the requirements of GB / T 7760-2003, with a thickness of 1.5mm±0.1mm. If plastic sheets or other sheets are used, the thickness is appropriately increased. The width of the steel sheet is 25mm±0.1mm, and the length is 60mm±1mm. Before the adhesive is applied, 17.5 mm and 17.5 mm at the ends of the steel sheet test piece are masked to prevent this area from being available for bonding to the rubb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com