Corrosion inhibitor for oil wells and preparation method

A corrosion inhibitor and oil well technology, applied in the field of oil drilling, can solve the problems of increased cost, complex corrosion medium, limited effect of corrosion inhibitor, etc., and achieve the effect of reducing contact and inhibiting corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

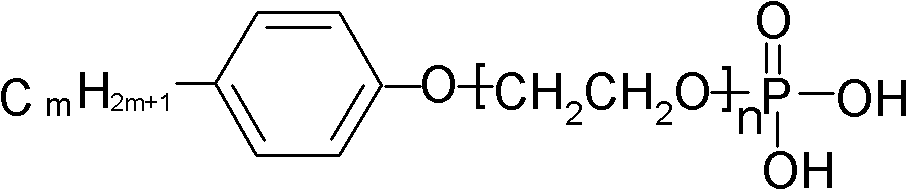

Method used

Image

Examples

preparation example Construction

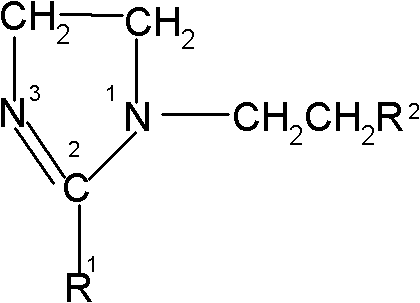

[0034] Preparation of imidazoline derivatives

[0035] (1) Put 0.15mol of oleic acid and 0.16mol of diethylenetriamine into a three-necked flask, add 30mL of xylene as a water-carrying agent, heat and stir, and raise the temperature to 180°C for 5 hours, and judge the reaction by taking liquid and measuring infrared spectrum Whether end; After the reaction finishes, use rotary evaporator to steam excess solvent, obtain imidazoline intermediate (R 1 is C 17 h 33 , R 2 is amino). Equimolar imidazoline intermediates and glacial acetic acid were put into a three-necked flask, and reacted at 120° C. for 2 hours to obtain imidazoline derivative 1#.

[0036] (2) Put 0.15mol oleic acid and 0.16mol hydroxyethylethylenediamine into a three-necked flask, add 30mL xylene as a water-carrying agent, heat and stir, heat up to 180°C for 5 hours, and measure the infrared spectrum by taking the liquid Judging whether the reaction ends; after the reaction ends, steam the excess solvent with...

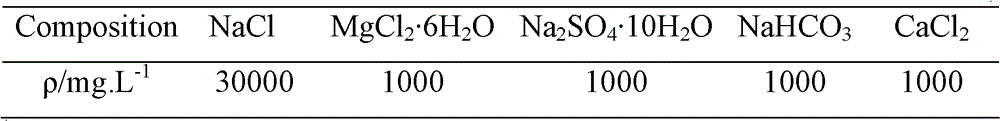

Embodiment 1

[0046] Take 25g of imidazoline derivative 1#, 30g of alkyl phosphate ester 1#, 0.5g of thiourea, add water to 100g, and stir well to prepare corrosion inhibitor A.

[0047] The evaluation results of corrosion inhibitor A are shown in Table 2:

[0048] Table 2 Static hanging test results

[0049]

Embodiment 2

[0051] Take 20g of imidazoline derivative 1#, 25g of alkyl phosphate 1# and 1g of thiourea prepared above, add water to 100g, stir well, and prepare corrosion inhibitor B. The corrosion inhibition performance was evaluated by the static coupon method, and the evaluation medium was simulated brine saturated with carbon dioxide. When the dosage was 50mg / L, the corrosion rate was 0.02548mm / a, and the corrosion inhibition rate was 95.12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion rate | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com