Method for improving low-temperature combustion soot emission and fuel economy of diesel engine

A fuel economy and low-temperature combustion technology, applied in mechanical equipment, engine control, machine/engine, etc., can solve problems such as fuel economy deterioration, soot emission increase, and increase the difficulty of combustion control, achieving combustion rate and Effects of shortening combustion duration, reducing heat transfer loss and exhaust loss, and improving control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) The control unit reads the speed signal of the sensor installed on the engine crankshaft and the engine load signal of the sensor installed on the accelerator pedal respectively, and judges the load and speed condition of the engine according to the speed signal and engine load signal ; The compression ratio of the engine cylinder is controlled at 16, and the height of the piston ring groove from the top surface is 4mm. The diameter of the piston of the engine cylinder is 65.6mm, the depth of the piston pit is 18.8mm, the radius of the arc of the piston pit is 6mm, the ratio of the shrinkage diameter to the cylinder diameter is 62.5%, and the ratio of the pit depth to the cylinder diameter is 17.9 %.

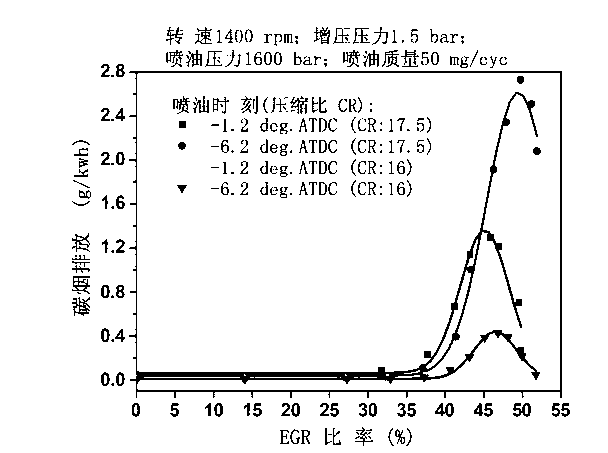

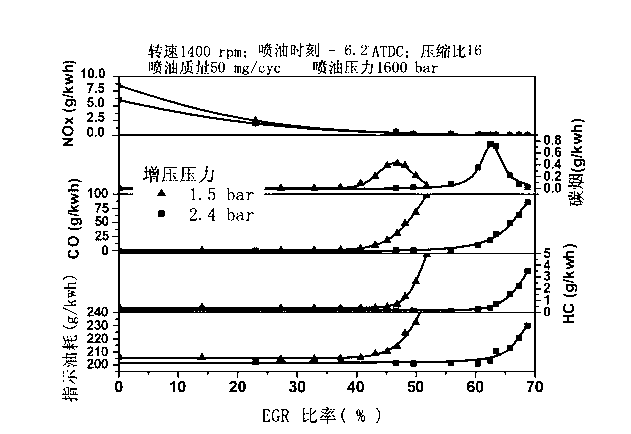

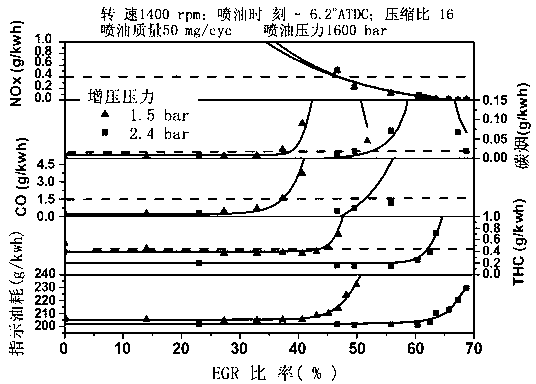

[0035] (2) If the judgment result in step (1) is the low-medium load condition, the intake air condition controller outputs a control signal according to the read intake air temperature parameter, and the control method is as follows: reduce the exhaust gas recirculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com