Composite thrust bearing set for novel screw drill

A technology of thrust bearing group and screw drilling tool, which is applied in the direction of bearings, shafts and bearings, rolling contact bearings, etc., which can solve the problems of high drilling pressure, complicated ball force, and large contact pressure, so as to reduce friction and wear, The effect of simple and compact structure and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

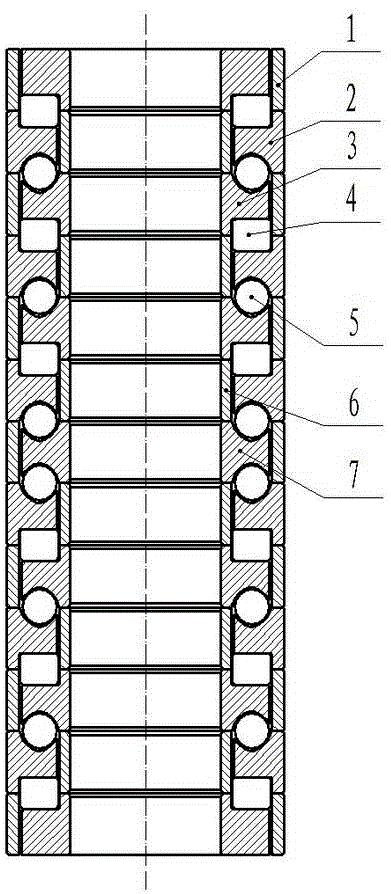

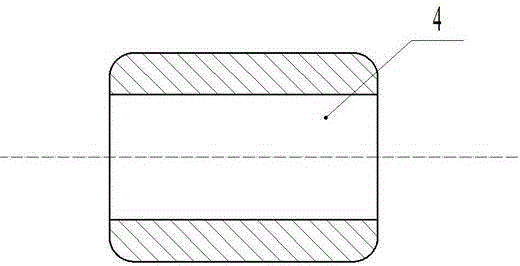

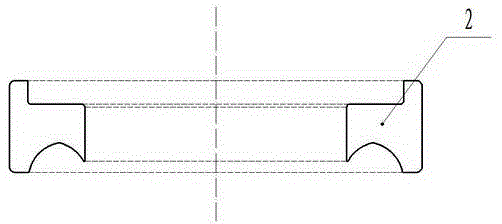

[0021] according to figure 1 As shown, the structure of the first embodiment of the composite thrust bearing for the novel screw drilling tool of the present invention is composed of six sets of four-point thrust ball bearings and six sets of hollow cylindrical roller thrust bearings, including outer spacer 1, inner spacer 6, Ball 5, hollow cylindrical roller 4, bearing inner ring 3, bearing inner ring 7, bearing outer ring 2, etc. The hollowness of the cylindrical roller is 50% to 65%, and both ends of the hollow cylindrical roller adopt rounded corner structure.

[0022] according to Figure 5 As shown, the structure of the second embodiment of the composite thrust bearing for the novel screw drilling tool of the present invention is composed of six sets of four-point thrust ball bearings and six sets of hollow tapered roller thrust bearings, including outer spacer 1, inner spacer 6, Ball 5, hollow tapered roller 10, bearing inner ring 9, bearing inner ring 7, bearing oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com