Condensation water circulating system of power station

A technology for condensed water and water circulation, applied in chemical instruments and methods, liquid degassing, separation methods, etc., can solve the problems of waste of manufacturing cost and operating cost, need to be optimized, poor speed regulation performance, etc., to reduce throttling loss, Best energy-saving effect, the effect of eliminating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

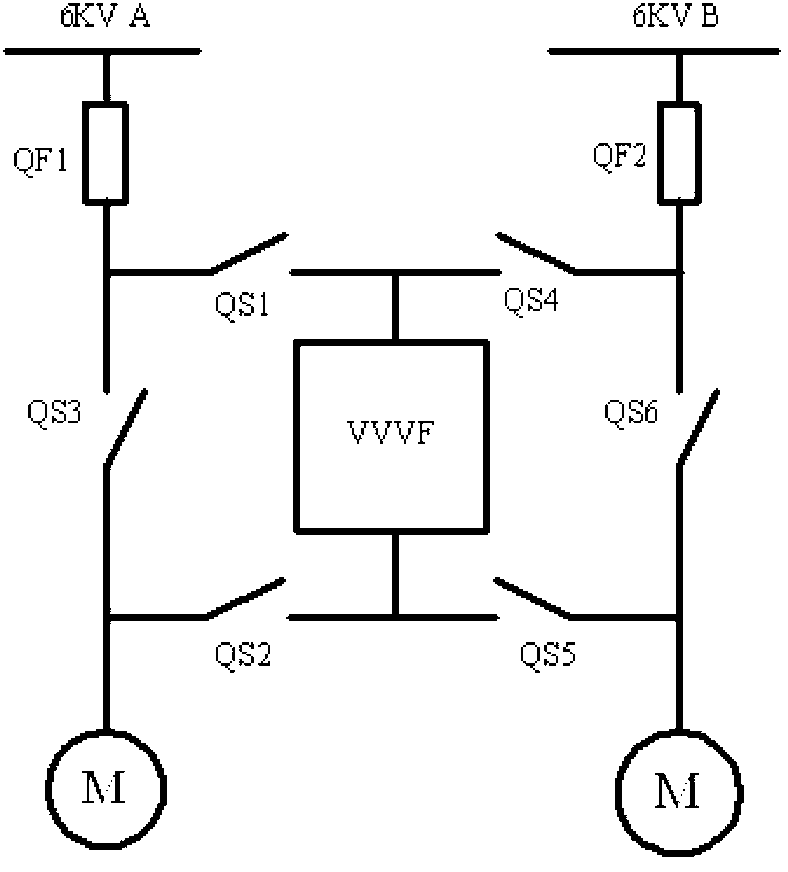

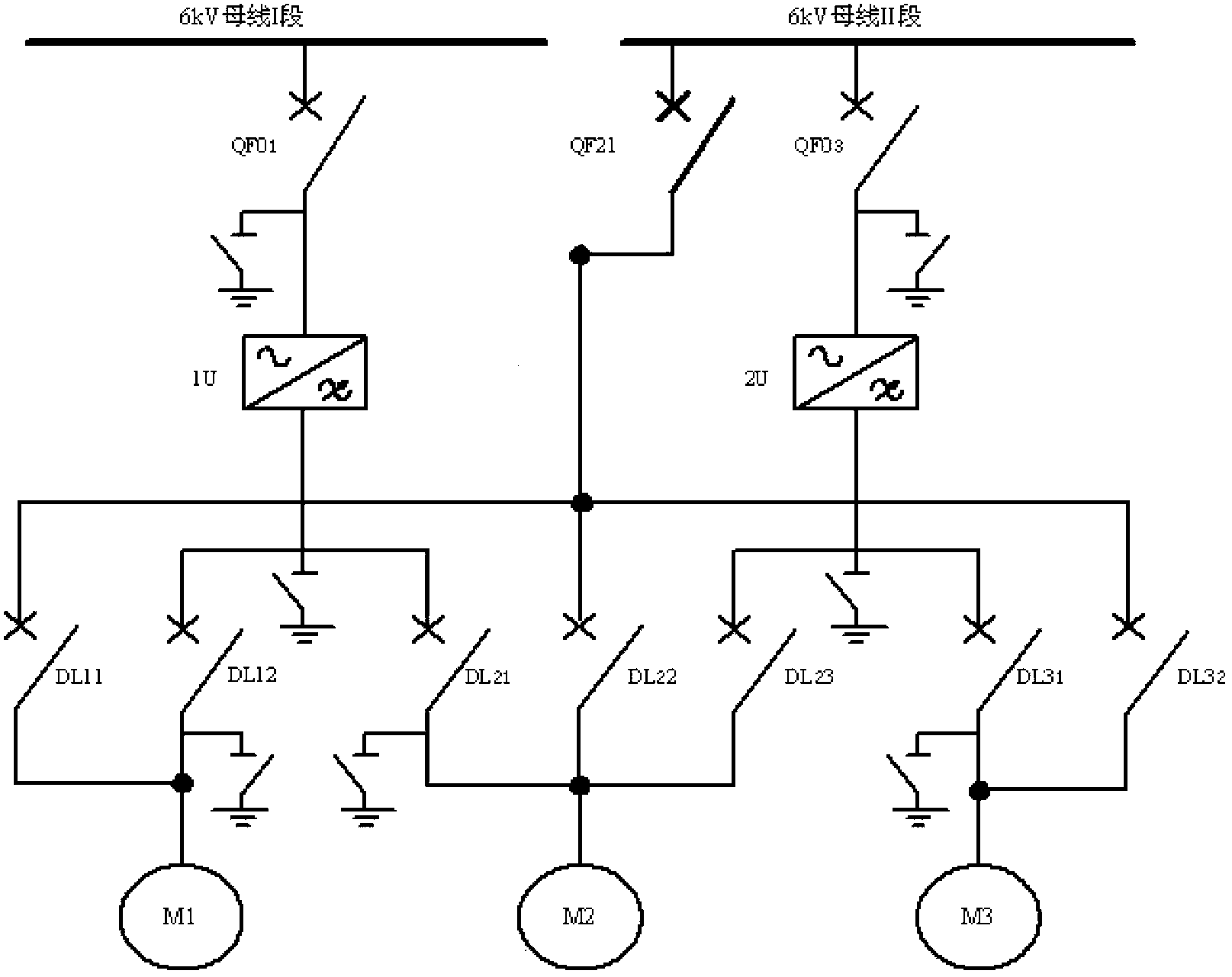

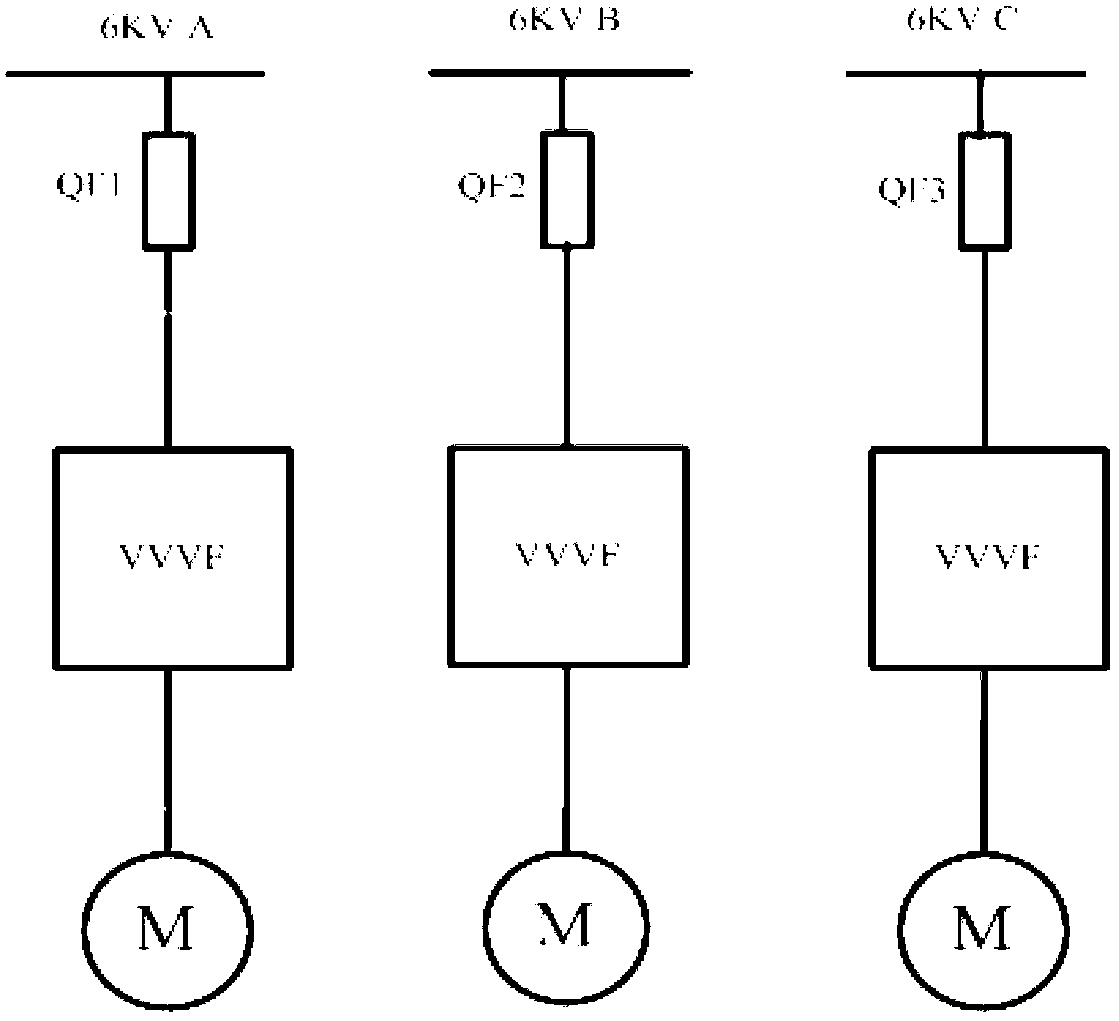

[0029] refer to Figure 5 and Figure 6 , The invention provides a condensed water circulation system of a power plant. The condensed water circulation system includes a condensed water pump unit 4 , and a condensed water pump 43 in the condensed water pump unit 4 drives the condensed water to flow to the low pressure heater unit 2 . The condensate is heated in the low pressure heater unit 2 and enters the subsequent deaerator. The water outlet of the low-pressure heater unit 2 is connected to the deaerator water tank 1, and the deaerator water tank 1 supplies water to the deaerator to remove oxidative gases in the condensed water and ensure the quality of boi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com