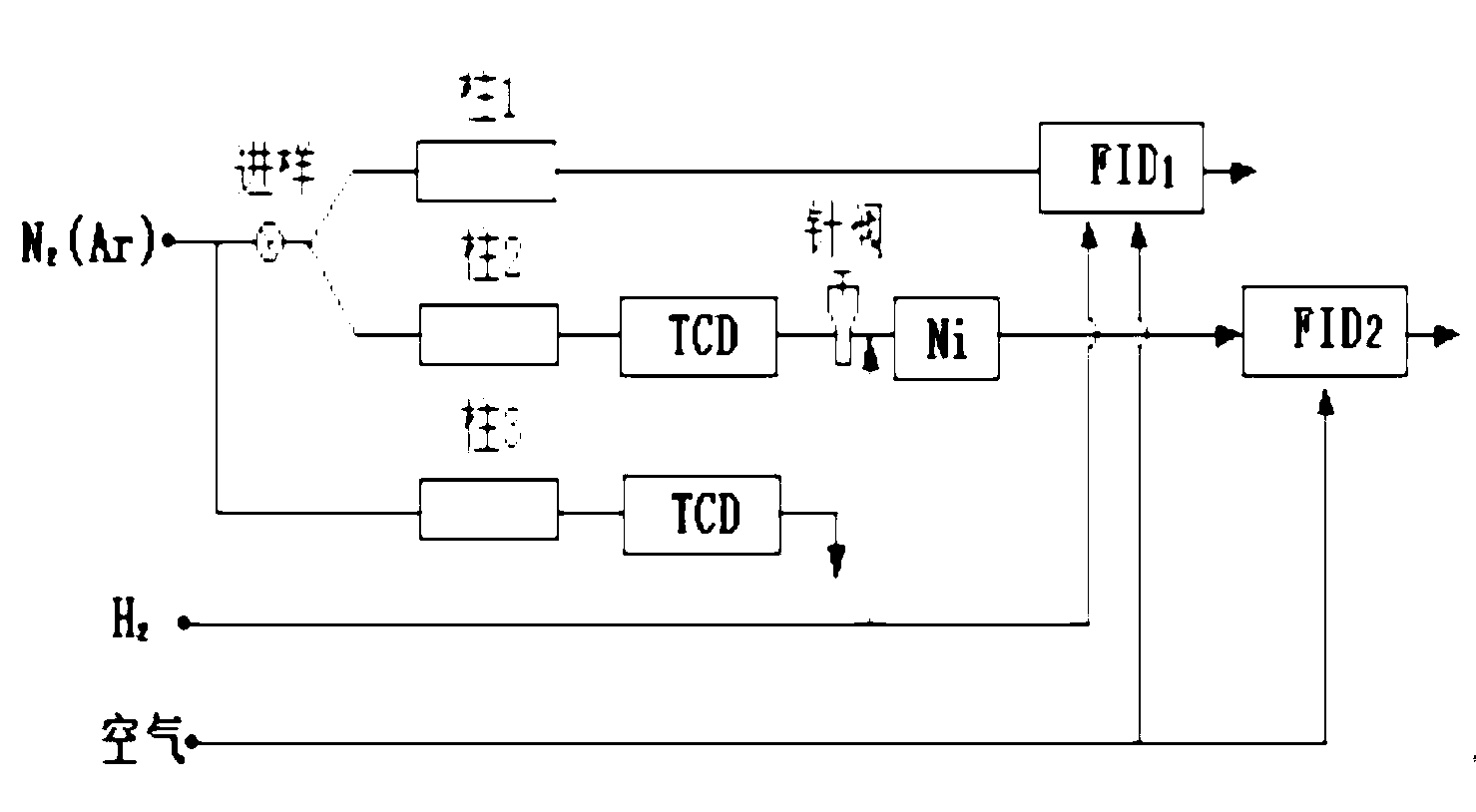

Process of one-sample introduction dual-detector gas chromatography and transformer oil analysis gas chromatography

A gas chromatography and dual detector technology, applied in the field of gas chromatography analysis, can solve the problems of high operational quality requirements of test personnel, unstable baseline jumping, high instrument requirements, etc., so as to reduce the cost of gas source, reduce difficulty and reduce cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

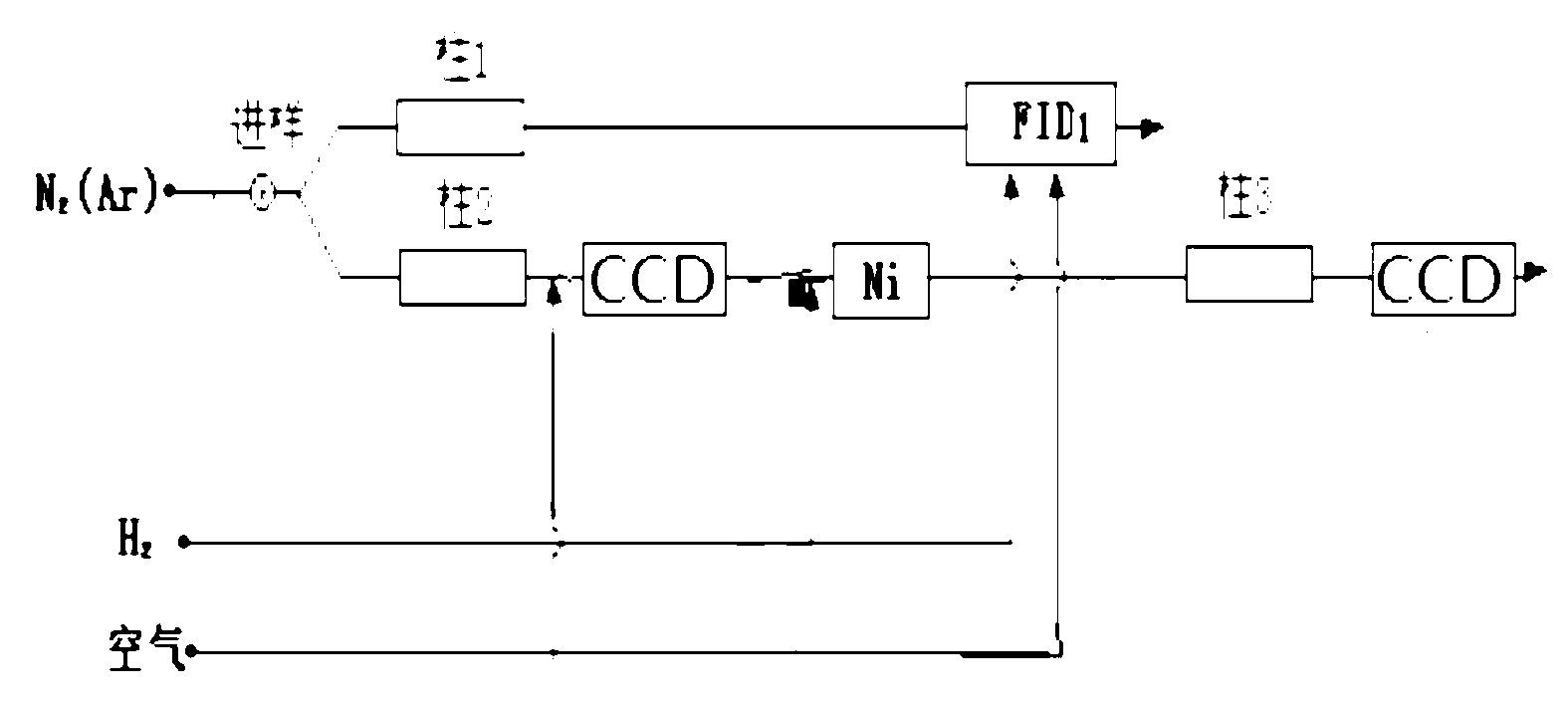

Embodiment 1

[0024] Example 1 A gas chromatograph with dual detectors for one injection, see figure 2 , including a sample inlet, three chromatographic columns A, B, C, a dual-arm catalytic combustion detector, a hydrogen flame detector, nickel catalytic converter and carrier gas system, and the chromatographic columns A and B are connected in parallel to the The position behind the inlet, where the chromatographic column A is connected in series with the hydrogen flame detector to form the first detection gas path, and the chromatographic column B is connected in series with the first arm of the catalytic combustion detector, the nickel catalytic converter, the chromatographic Column C and the second arm of the catalytic combustion detector form the second detection gas path; the chromatographic column A can at least separate methane (CH 4 ), ethane (C 2 h 6 ), ethylene (C 2 h 4 ), acetylene (C 2 h 2 ); the chromatographic column B can at least separate hydrogen (H 2 ), carbon mon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com