Manufacturing method of shadow figure model based on common three-dimensional model

A shadow puppet model and three-dimensional model technology, applied in 3D modeling, image data processing, instruments, etc., can solve the problems of digitalization of shadow puppetry, research on the artistic value of shadow puppetry, and non-realistic rendering of traditional shadow puppetry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to illustrate the specific implementation manner of the present invention more vividly, this embodiment further elaborates the present invention by taking a figure model of a shadow puppet as an example.

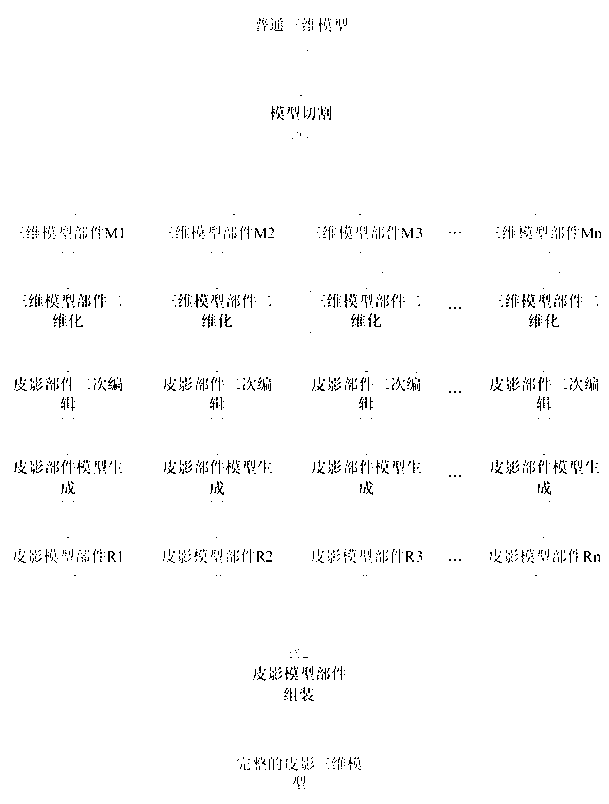

[0053] The steps of the shadow puppet model making method based on the common three-dimensional model are as follows: figure 1 As shown, the common 3D model is used as the input material, and the technology of model cutting (grid division), 3D model parts two-dimensionalization, shadow play part secondary editing, shadow play part model generation and shadow play model part assembly is used to make the specific performance for:

[0054] Step 1 Segmentation of 3D model

[0055] The segmentation part of the 3D model divides the original and complete 3D model material of a character into eleven parts: head, upper body, lower body, two legs, two upper arms, and two lower arms to reflect the composition characteristics of traditional shadow puppets.

[0056] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com