Solar cell rear panel, preparation method of solar cell rear panel and solar cell module

A solar cell and backplane technology, which is applied in the field of solar cells, can solve the problems that solar cell backplanes are difficult to ensure high insulation and weather resistance and low cost at the same time, and achieve the effects of protecting the internal structure, improving insulation and weather resistance, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

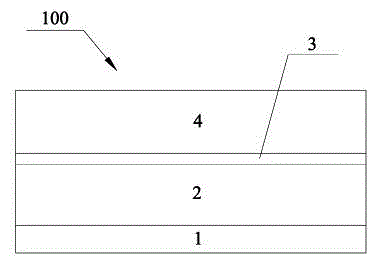

[0026] The present invention also provides a method for preparing the solar cell backsheet, comprising the following steps:

[0027] A. Carry out anodic oxidation on one surface of the metal aluminum layer, or, coat a fluorocarbon coating on one surface of the metal aluminum layer, and form a back protection layer on this surface of the metal aluminum layer;

[0028] B. Coating an adhesive on one side of the PET polyester film layer, and after drying, thermally pressing the side coated with the adhesive and the surface of the metal aluminum layer without the back protective layer to obtain the solar battery back sheet.

[0029] Preferably, in step B, the drying temperature is 70-100° C., and the drying time is 3-5 minutes. More preferably, the drying temperature is 80-90° C., and the drying time is 3-5 minutes. The temperature of thermoforming is 70-100°C, preferably 80-90°C.

[0030] As the common knowledge of those skilled in the art, before coating the adhesive on one sid...

Embodiment 1

[0038] (1) Mix PET resin 45kg, PVDF resin 35kg, PEN resin 18kg, TiO 2 Powder 1kg, antioxidant 168 1kg were mixed evenly, followed by drying, heating extrusion, forming, longitudinal stretching, transverse stretching, trimming and coiling to obtain the PET polyester film of this embodiment, with a film thickness of 150 μm;

[0039] (2) The PET polyester film obtained in step (1) is first degreased and corona treated, and then one side is coated with an adhesive (polyurethane-based heat-curing adhesive, polyurethane The mass ratio of isocyanic acid to isocyanic acid is 100:30), and dried at 90°C for 5 minutes, and the thickness of the adhesive layer formed after drying is 1 μm;

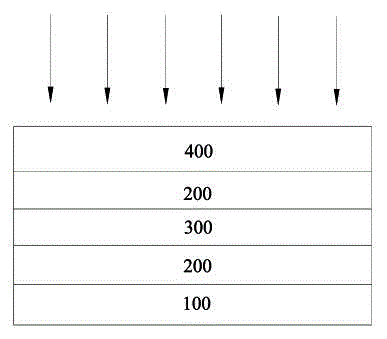

[0040] (3) The adhesive-coated side of the PET polyester film obtained in step (2) and the non-anodized side of the single-sided anodized aluminum foil (the thickness of the aluminum foil is 200 μm, and the thickness of the anodized layer is 20 μm) are press-molded at 90°C , to obtain the solar battery...

Embodiment 2

[0042] (1) Put 35kg of PET resin, 45kg of PTFE resin, 17kg of PEN resin, TiO 2 Powder 2kg, antioxidant 1010 1kg were mixed evenly, followed by drying, heating extrusion, forming, longitudinal stretching, transverse stretching, trimming and coiling to obtain the PET polyester film of this embodiment, with a film thickness of 200 μm;

[0043] (2) The PET polyester film obtained in step (1) is first degreased and corona treated, and then one side is coated with an adhesive (polyurethane-based heat-curing adhesive, polyurethane The mass ratio of isocyanic acid to isocyanic acid is 100:30), and dried at 80°C for 5 minutes, and the thickness of the adhesive layer formed after drying is 2 μm;

[0044] (3) The adhesive-coated side of the PET polyester film obtained in step (2) and the non-anodized side of the single-sided anodized aluminum foil (the thickness of the aluminum foil is 150 μm, and the thickness of the anodized layer is 15 μm) are press-molded at 80°C , to obtain the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com