Prefabricated substation

A prefabricated substation and installation hole technology, which is applied in the direction of cooling/ventilation of power distribution substation, substation/switchgear, etc., can solve the problems of affecting work stability, shortening service life, deformation of door panels, etc., and achieves good protection and support effect , to ensure the stability of work, to enhance the effect of heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

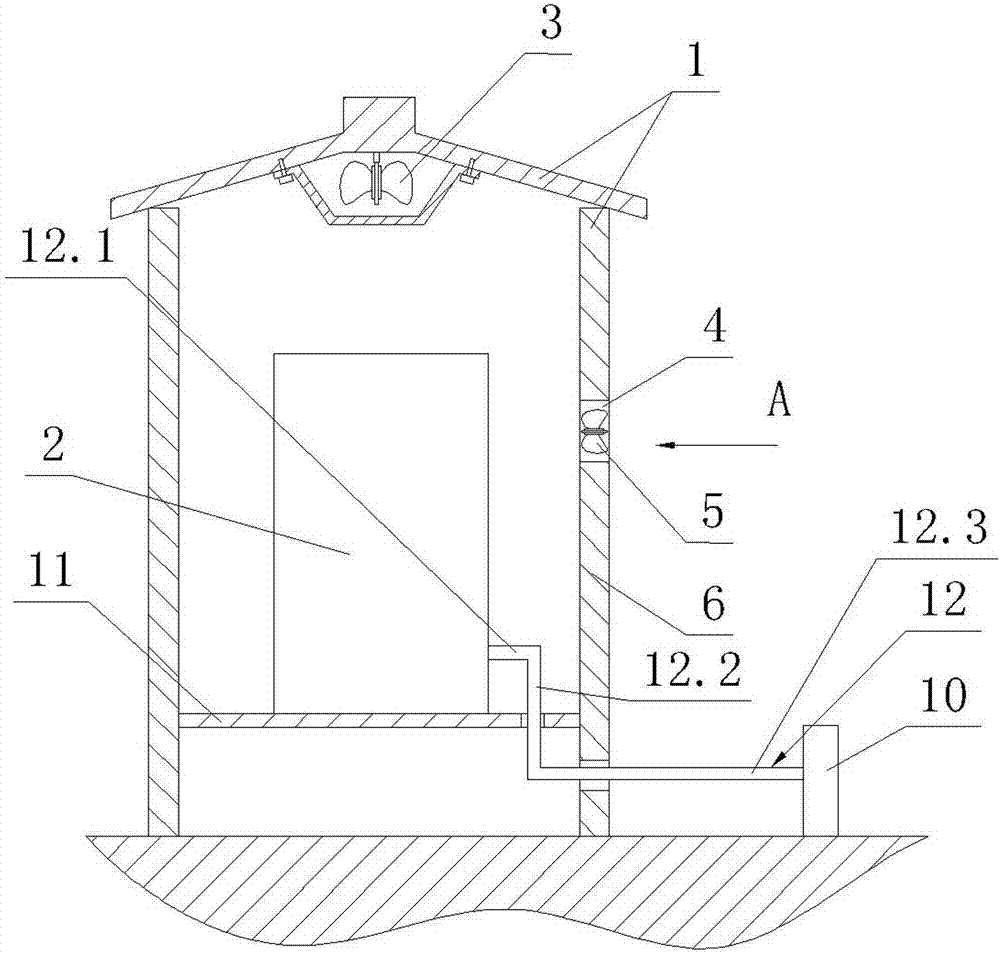

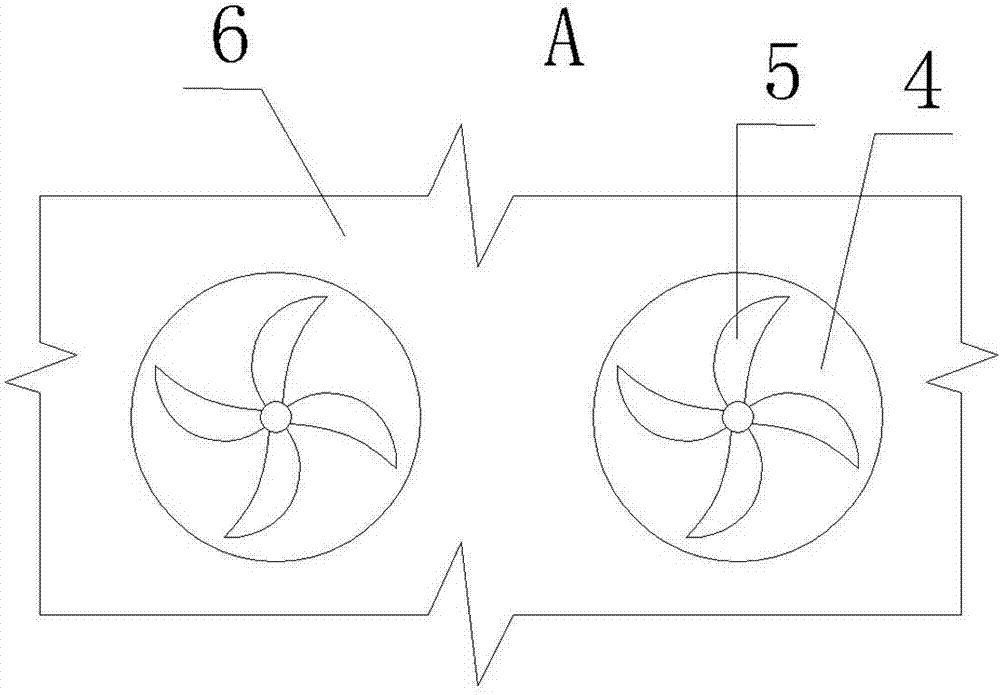

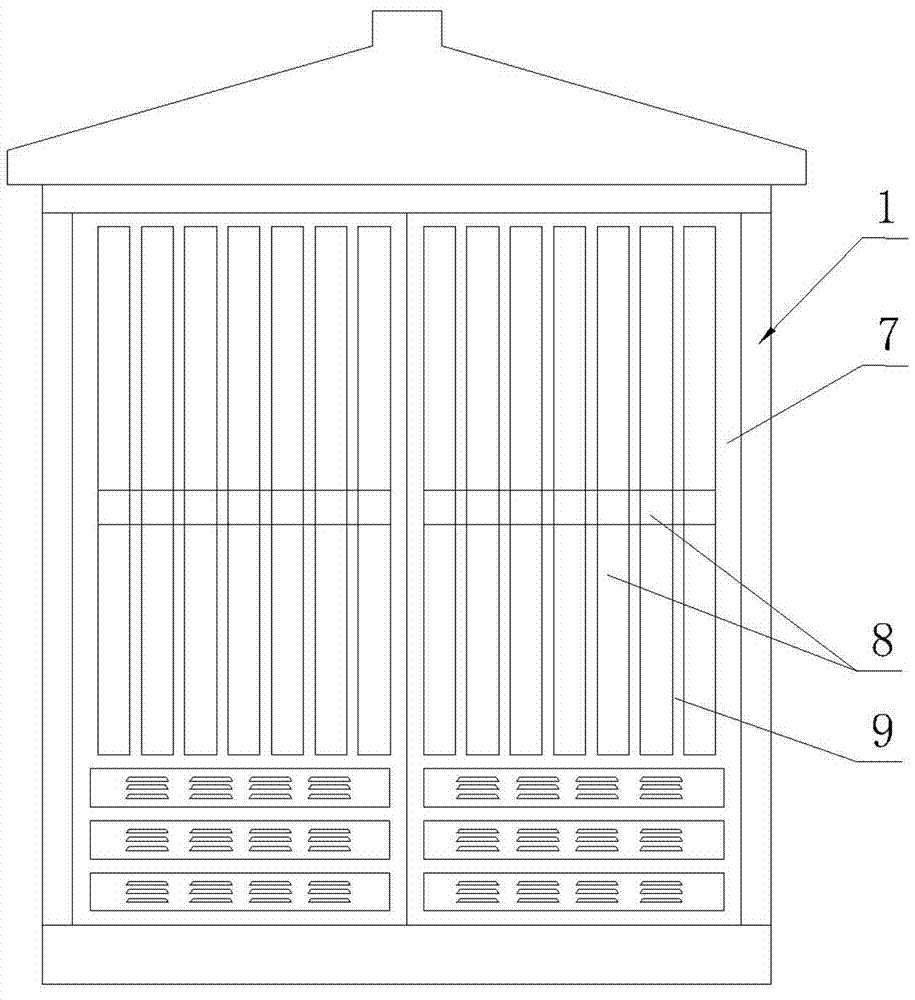

[0016] Such as figure 1 , figure 2 , image 3 As shown, the prefabricated substation of the present invention includes a housing 1 on which a door 7 made of steel plate is hinged, and a distribution transformer 2 is installed in the housing 1 . A first air suction and exhaust fan 3 is suspended from the top of the housing 1 , and the first air suction and exhaust fan 3 is located above the distribution transformer 2 . The side wall 6 of the housing is penetrated with mounting holes 4 , specifically, two mounting holes 4 are provided on the left side wall 6 of the housing, and a second suction and exhaust fan 5 is provided in each mounting hole 4 . The total area of the two mounting holes 4 accounts for one percent of the surface area of a single side wall 6 of the housing 1 . Such an area ratio can not only ensure effective heat dissip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com