Method and appliances for low temperature pasteurisation of liquid foods and removal of oxygen from liquid foods by decompression and/or high linear or rotary acceleration

A technology of rotational acceleration and linear acceleration, which is used in the field of sterilizing liquid food and removing oxygen and equipment at low temperature through decompression and/or large linear or rotational acceleration, which can solve the problem of rising, changing, destroying, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 3 approach

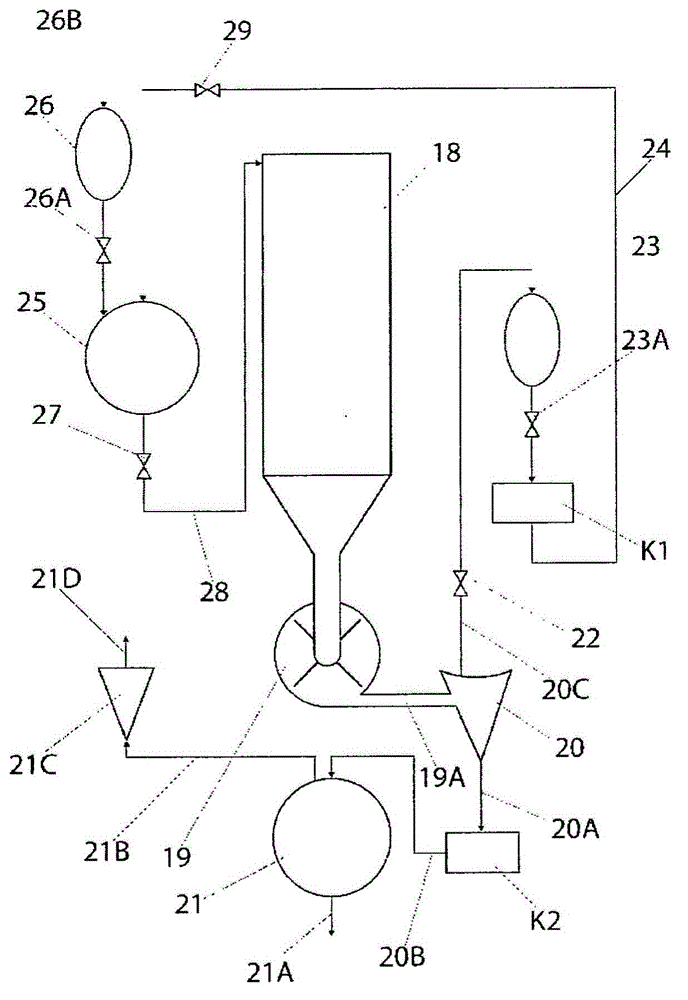

[0246] Figure 4 The third embodiment variant shown for the purpose of displaying the following:

[0247] 1 – removal of between 90% and 95% of the oxygen and any other gases dissolved in the liquid to be treated and in the interior of all plant cells and in the interior of contaminating microbial cells in a single operation at low temperature, and In both operations, up to 99%,

[0248] 2 – prevent oxygen and any extracted gases from returning to the liquid to be treated, and

[0249] 3 – Sterilize these liquids at low temperature without loss of nutrients.

[0250] Figure 4 is a schematic front view of the device forming the third embodiment variant, the working of which is as follows: In the figure we can see the product to be treated tank (30), which receives the product to be treated via the pipe (30A) And also receives via pipe (39A) the liquid recovered elsewhere (as it aptly shows) in which the product to be treated tank (30) maintains its internal pressure at par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com