Shape retaining film and production method therefor, laminated filmtape, self-adhesive filmtape, anisotropic thermal conductive film, and shape retaining fiber

A manufacturing method and a technology for a substrate layer, which are applied in fiber processing, chemical instruments and methods, layered products, etc., can solve the problem of time-consuming and laborious aluminum separation and waste, and achieve excellent shape retention, high tensile elastic modulus, Excellent longitudinal crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0173] Hereinafter, the present invention will be specifically described based on examples. The technical scope of the present invention is not limited to these Examples.

[0174] 1. Various raw materials

[0175] HDPE: high-density polyethylene (trade name "Novatec HD HB530", manufactured by Japan Polyethylene Corporation), density: 965kg / m 3 , Mw / Mn: 15.8, MFR (190°C): 0.36g / 10min

[0176] LLDPE (1): Linear low-density polyethylene (trade name "Evolue H SP4505", manufactured by Prime Polymer Co., Ltd.),

[0177] LLDPE (2): Linear low-density polyethylene (trade name "Moretec0278G", manufactured by Prime Polymer Co., Ltd.)

[0178] Thermoplastic elastomer: α-olefin copolymer (trade name "Tafmer A4090", manufactured by Mitsui Chemicals), melting point Tm2: 77°C

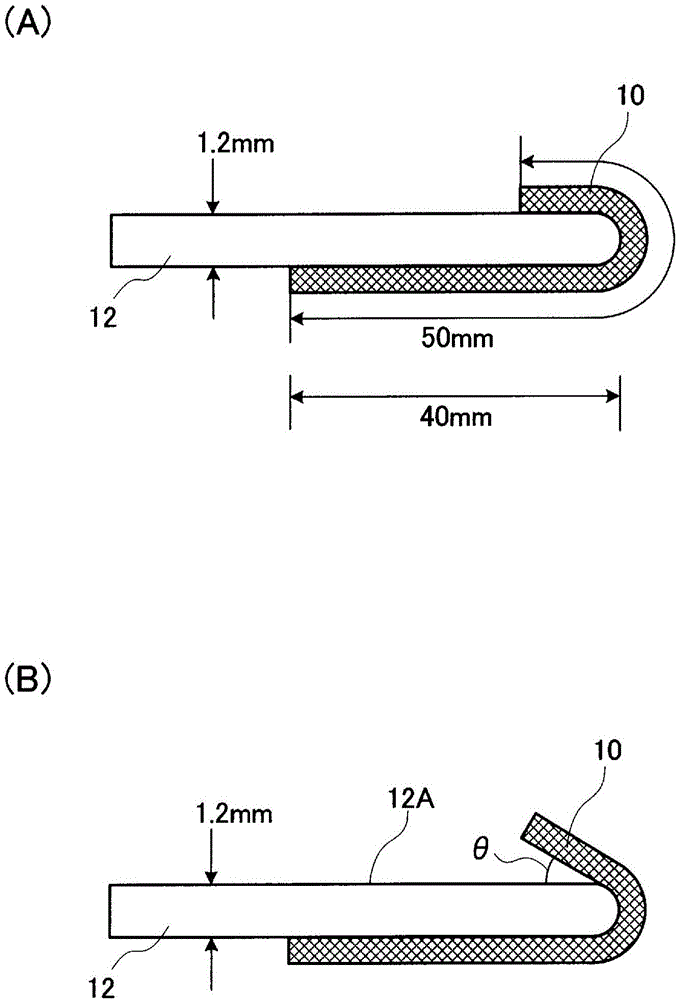

[0179] 2. Manufacture of shape-retaining film (Example 1)

[0180] HDPE was used as a raw material for the base material layers (A) and (B), and a thermoplastic elastomer was used as a raw material for the soft l...

Embodiment 2

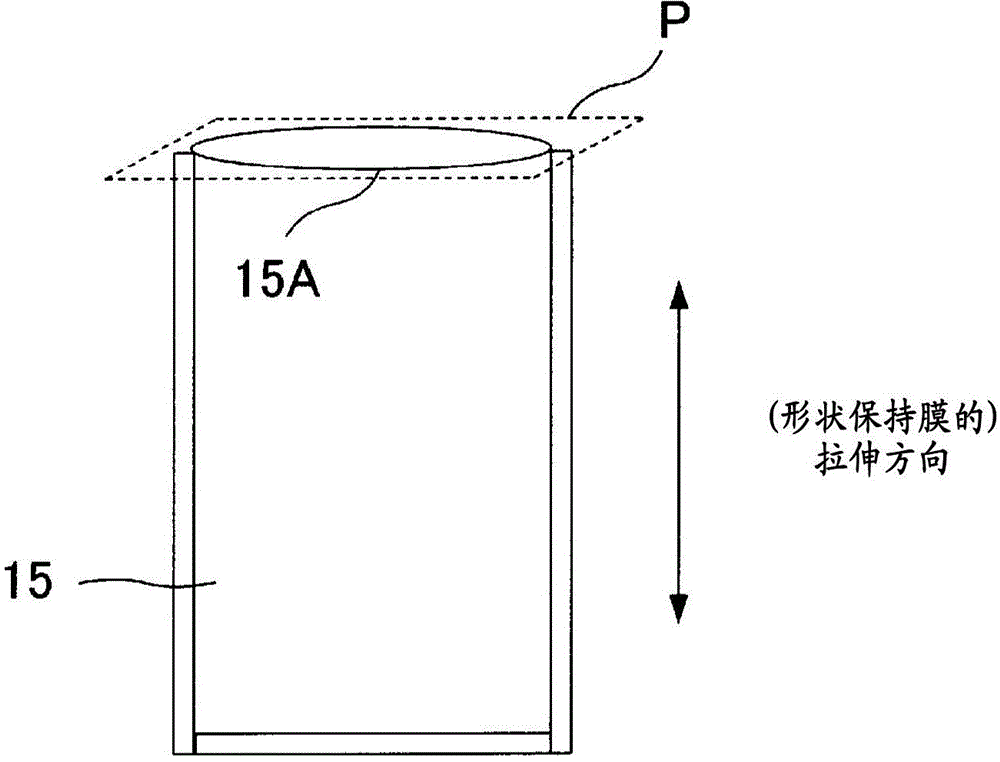

[0183] Except having stretched the base film to a draw ratio of 20 times, it carried out similarly to the said Example 1, and obtained the uniaxially stretched film. In addition, the thermal conductivity in the stretching direction (X direction) of the obtained uniaxially stretched film was 7.86 W / mK, and the thermal conductivity in the direction substantially perpendicular to the X direction (Y direction) was 0.289 W / mK.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com