Three-level separating biogas slurry drip-irrigation fertilization system

A technology of drip irrigation and fertilization and three-stage separation, which is applied in the fields of filtration separation, separation method, and pressure spreading method of liquid fertilizer, can solve the problems of affecting the promotion of biogas slurry, high price, and poor filtering effect of the filter screen, which is conducive to the promotion of biogas slurry. , the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

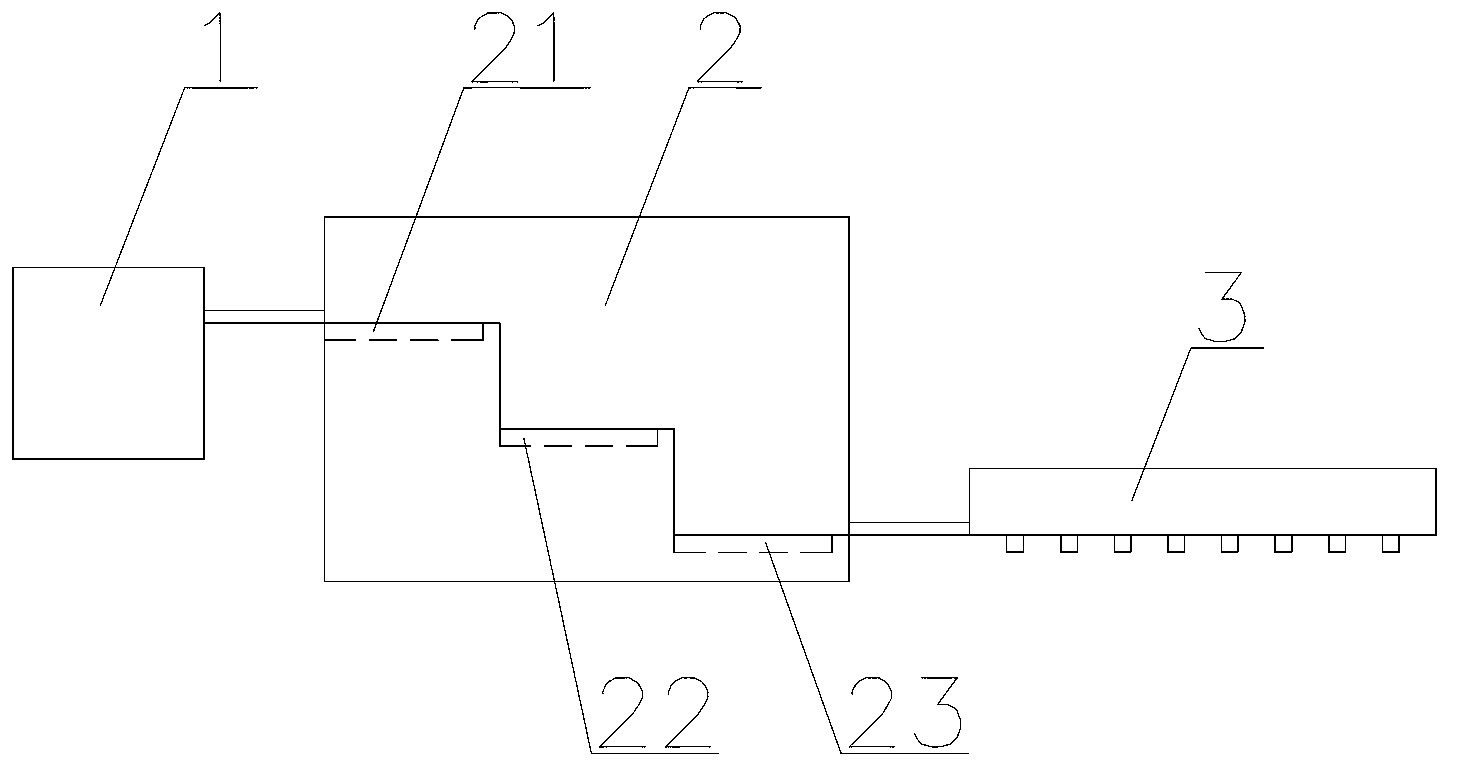

[0016] Such as figure 1 Shown is a three-stage separated biogas slurry drip irrigation and fertilization system, including a biogas slurry chamber 1, a biogas slurry pretreatment tank 2, and a drip irrigation device 3. The biogas slurry pretreatment tank 2 has a three-level ladder structure that is successively lowered. Among them, the highest step surface is set as the first-level sedimentation zone 21, the middle step surface is set as the second-level settling zone 22, and the lowest step surface is set as the third-level settling zone 23; the liquid inlet of the biogas slurry pretreatment tank 2 is set at the first level Within the scope of the sedimentation area 21, the liquid outlet of the biogas slurry pretreatment tank 2 is set within the scope of the tertiary sedimentation area 23, and the biogas slurry chamber 1 is connected to the liquid inlet of the biogas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com