Preparation method of collagen film for guided tissue regeneration

A technology to guide regeneration and collagen membranes, applied in medical science, surgery, etc., can solve the problems of loss of space maintenance ability, low tensile strength of collagen membranes, fast degradation speed, etc., and achieve excellent controllable degradation performance, excellent mechanical properties, good repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

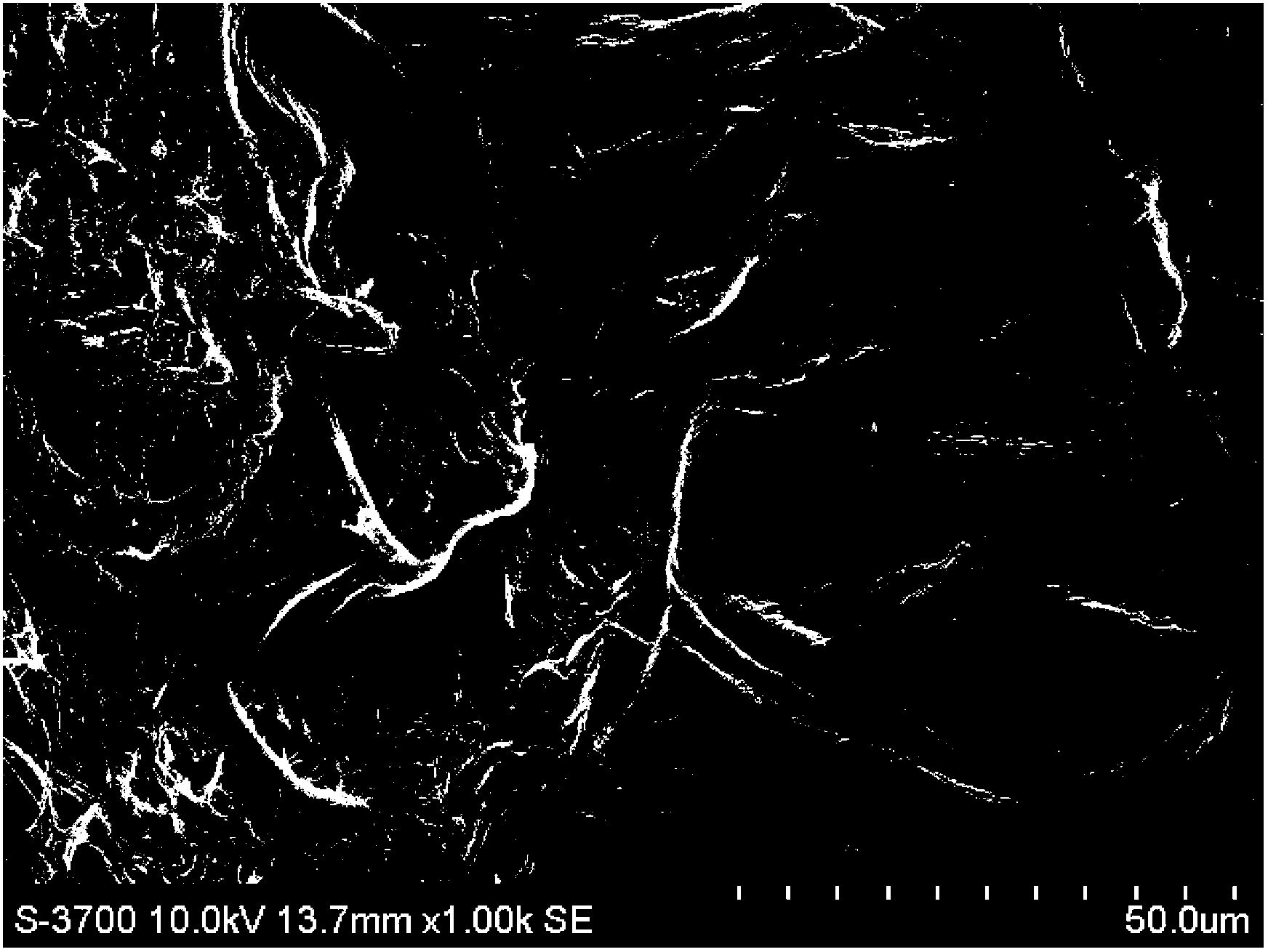

[0033] A method for preparing a collagen membrane for guided tissue regeneration, comprising the steps of:

[0034] (1) Dissolve collagen in 0.1M acetic acid solution at 25°C to obtain a collagen solution with a concentration of 6 mg / ml;

[0035] (2) Slowly adjust the pH value of the collagen solution obtained in step (1) to 7 with 0.1M sodium hydroxide solution, and keep it for 30 minutes;

[0036] (3) shear and stir the collagen solution obtained in step (2) with an electric mixer at 3000r / min for 5 minutes to obtain a collagen emulsion;

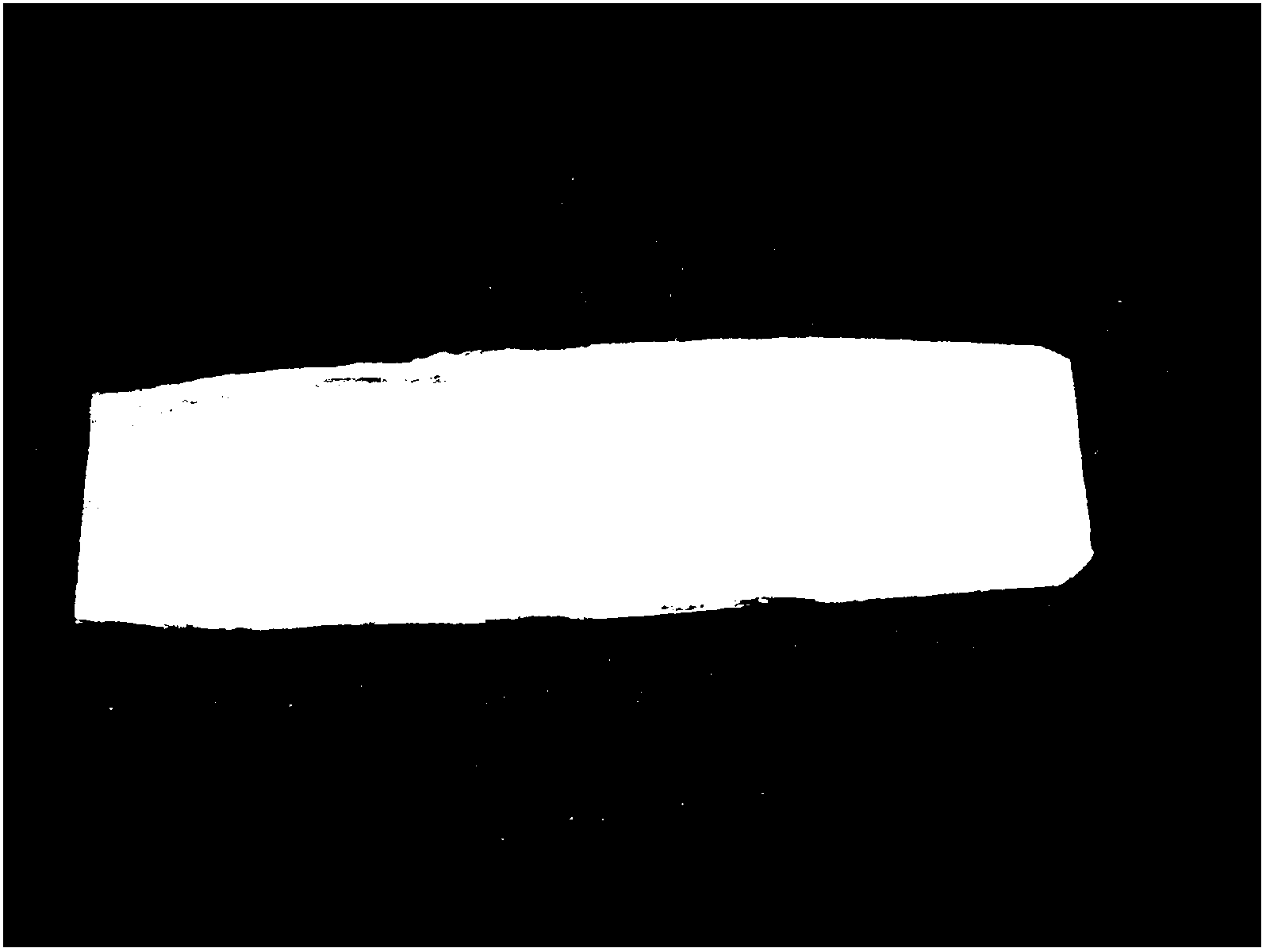

[0037] (4) Centrifuge the emulsion in step (3) at 2000r / min for 8 minutes. At this time, the collagen floats on the surface of the solvent, and collect the collagen film on the solution;

[0038] (5) Forming the collagen film obtained in step (4), then freeze-drying, and vacuum thermal crosslinking at 120°C;

[0039] (6) Packaging, irradiation sterilization.

[0040] Sample tear strength: 31.0MPa.

Embodiment 2

[0042] A method for preparing a collagen membrane for guided tissue regeneration, comprising the steps of:

[0043] (1) Dissolve collagen in 0.1M hydrochloric acid solution at 30°C to obtain a collagen solution with a concentration of 5 mg / ml;

[0044] (2) Slowly adjust the pH value of the collagen solution obtained in step (1) to 5 with 0.1M sodium hydroxide solution, and keep it for 10 minutes;

[0045] (3) The collagen solution in step (2) is sheared and stirred for 5 seconds under the condition of 15000 r / min with a tissue masher to obtain a collagen emulsion;

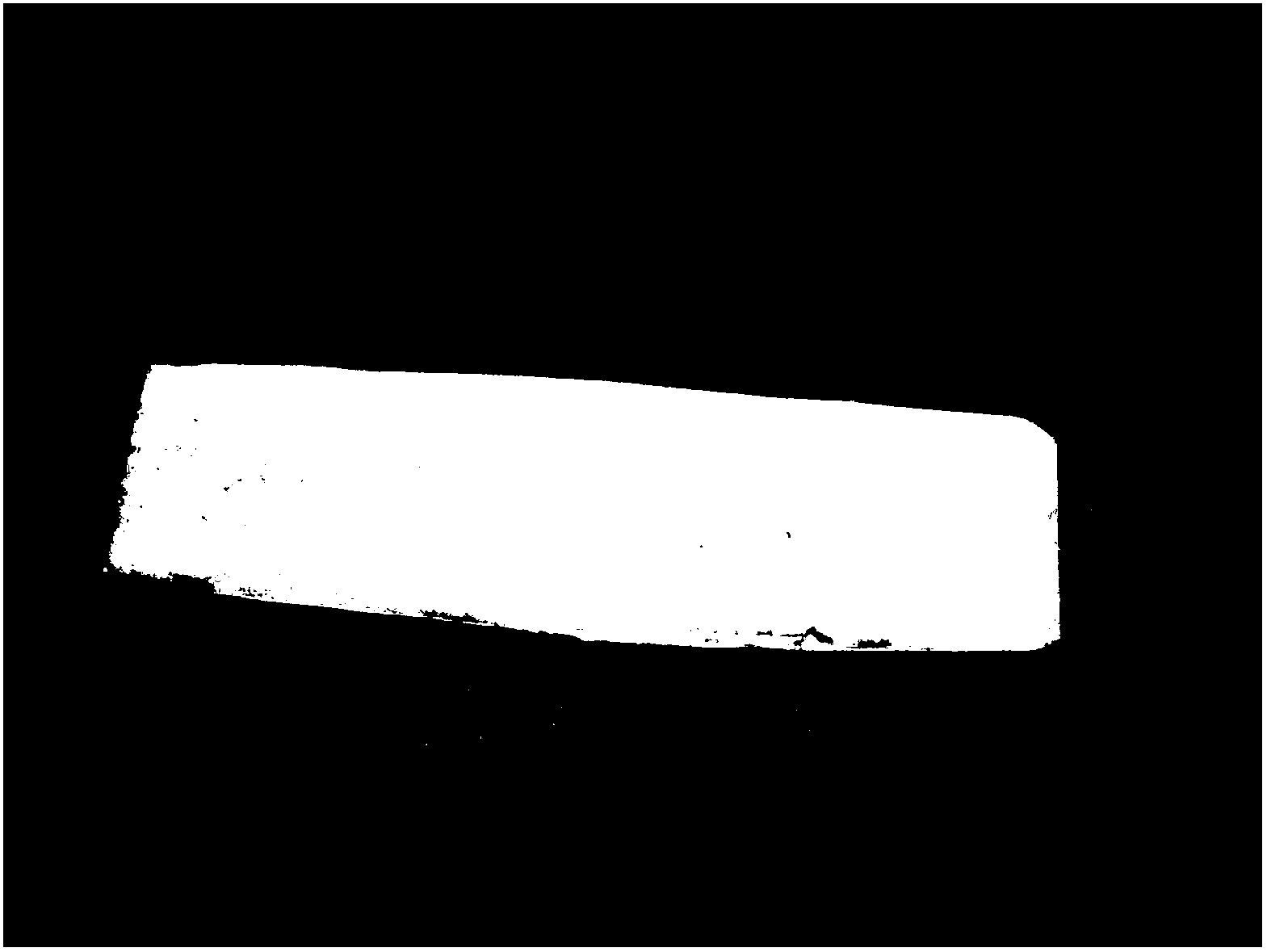

[0046] (4) Centrifuge the emulsion in step (3) at 1000r / min for 10 minutes. At this time, the collagen floats on the surface of the solvent, and collect the collagen film on the solution;

[0047] (5) Forming the collagen film obtained in step (4), freeze-drying at -20°C, and thermally crosslinking under vacuum at 140°C;

[0048] (6) Soak the collagen membrane obtained in step (5) in 1% glutaraldehyde solution fo...

Embodiment 3

[0052] A method for preparing a collagen membrane for guided tissue regeneration, comprising the steps of:

[0053] (1) Dissolve collagen in 0.1M hydrochloric acid solution at 4°C to obtain a collagen solution with a concentration of 10mg / ml;

[0054] (2) Slowly adjust the pH value of the collagen solution obtained in step (1) to 8 with 0.1M ammonia water, and keep it for 10 minutes;

[0055] (3) The collagen solution obtained in step (2) is sheared and stirred for 15 seconds under the condition of 15000 r / min with a tissue masher to obtain a collagen emulsion;

[0056] (4) Centrifuge the emulsion in step (3) at 6000r / min for 5 minutes. At this time, the collagen floats on the surface of the solvent, and collect the collagen film on the solution;

[0057] (5) Forming the collagen film obtained in step (4), freeze-drying at -20°C, and vacuum thermal crosslinking at 110°C;

[0058] (6) Put the collagen film obtained in step (5) into 1% EDC-NHS solution (weigh a certain amount ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com