An Axial-Radial Reactor Structure for Sulfur Tolerance Shift Process

A sulfur-resistant shift and reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems that the reactor volume cannot be fully utilized, the equipment processing precision is high, and the axial effect is not obvious. To achieve the effect of reducing equipment weight, improving utilization rate and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

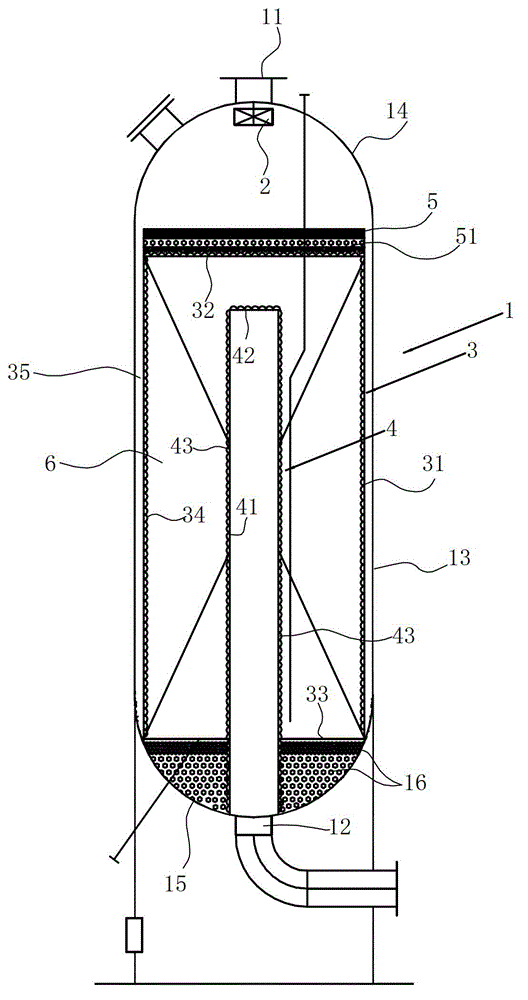

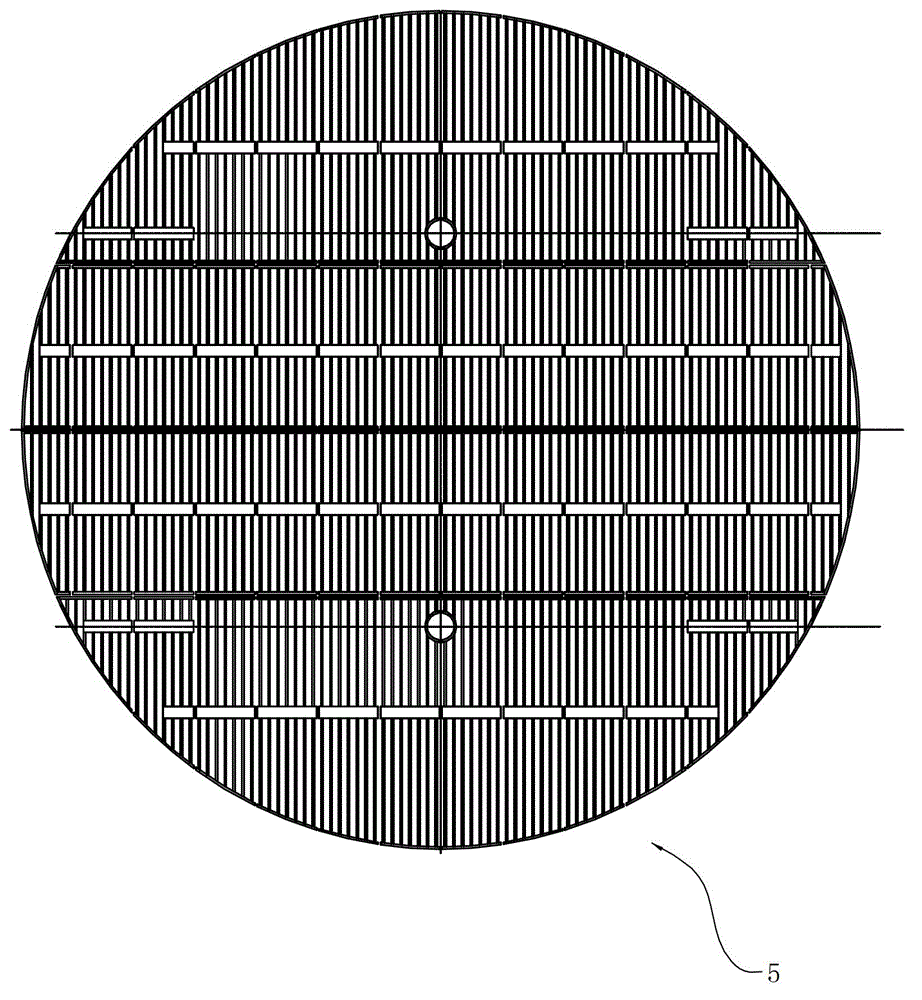

[0022] Such as figure 1 with figure 2 As shown, the axial radial reactor structure for the sulfur-tolerant shift process includes:

[0023] Housing 1, the top of the housing is provided with an air inlet 11, and the bottom of the housing is provided with an air outlet 12; the housing in this embodiment includes a cylindrical main body 13 and upper and lower ends of the cylindrical main body. The length-to-diameter ratio of the cylindrical main body of the sealing head 14 and the lower sealing head 15 is 2. The length-to-diameter ratio of the cylindrical body can be determined according to needs, preferably, it can be 1.0-5.0, and within this range, the weight of the entire reactor can be minimized under the condition of satisfying the process and pressure drop. The lower head 15 is filled with refractory balls, and these refractory balls c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com