Garbage water classification system

A technology for water classification and garbage, which is applied in the field of water treatment and garbage classification system, can solve the problems of harsh surrounding environment of the working environment, inaccessibility of staff, billowing dust in the workshop, etc., and achieves convenient maintenance of equipment, improvement of working environment, and temperature change little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

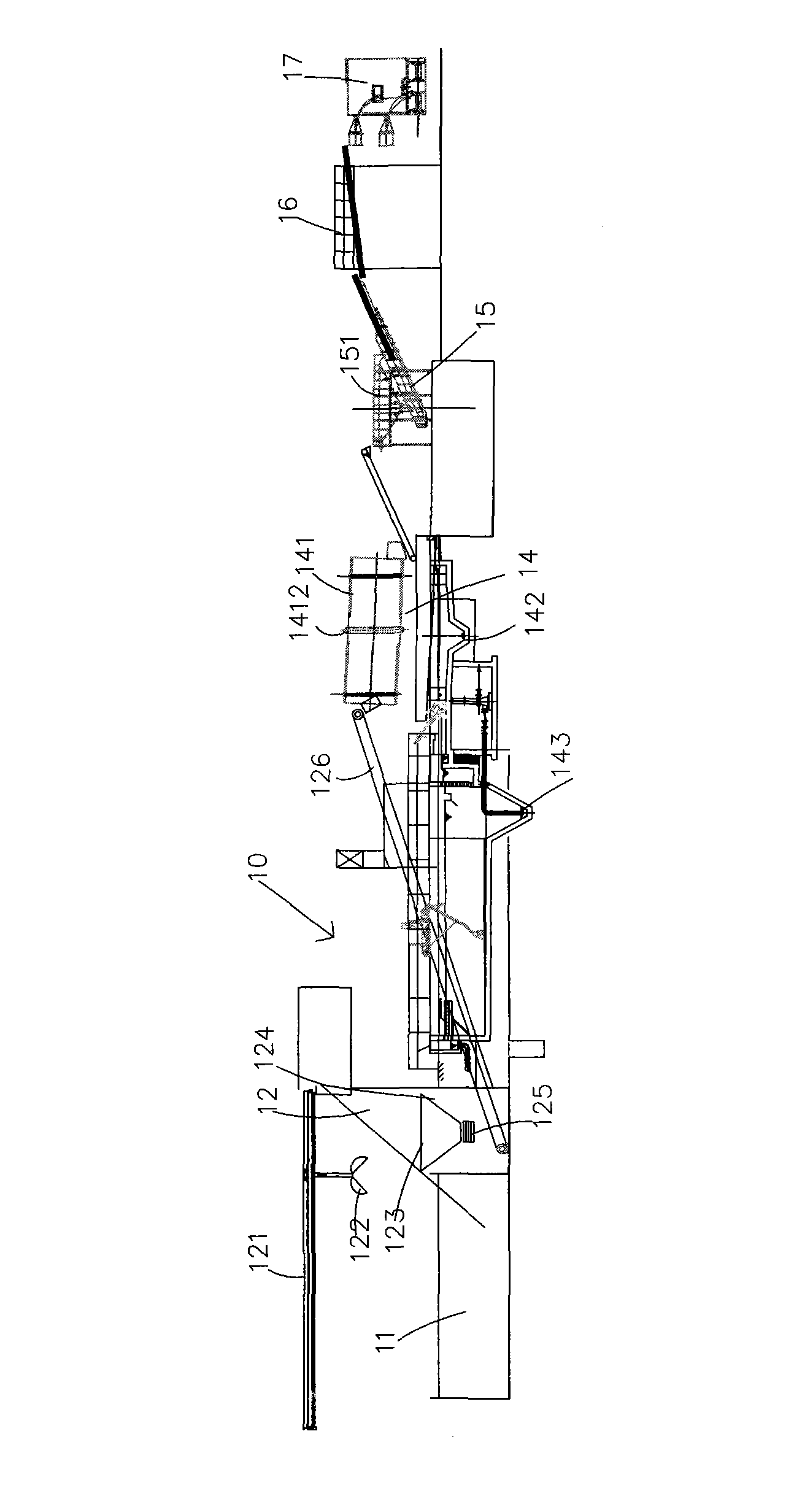

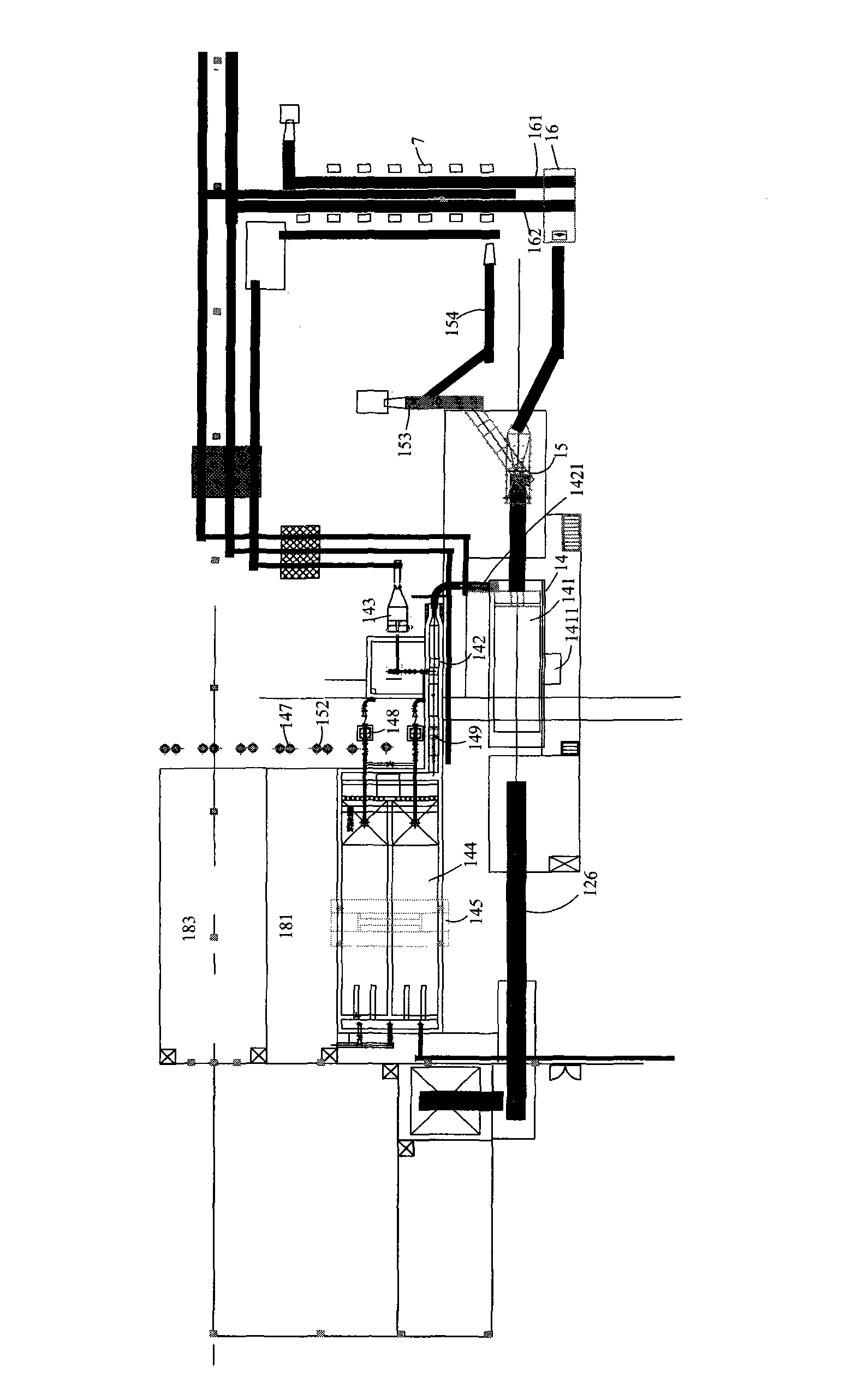

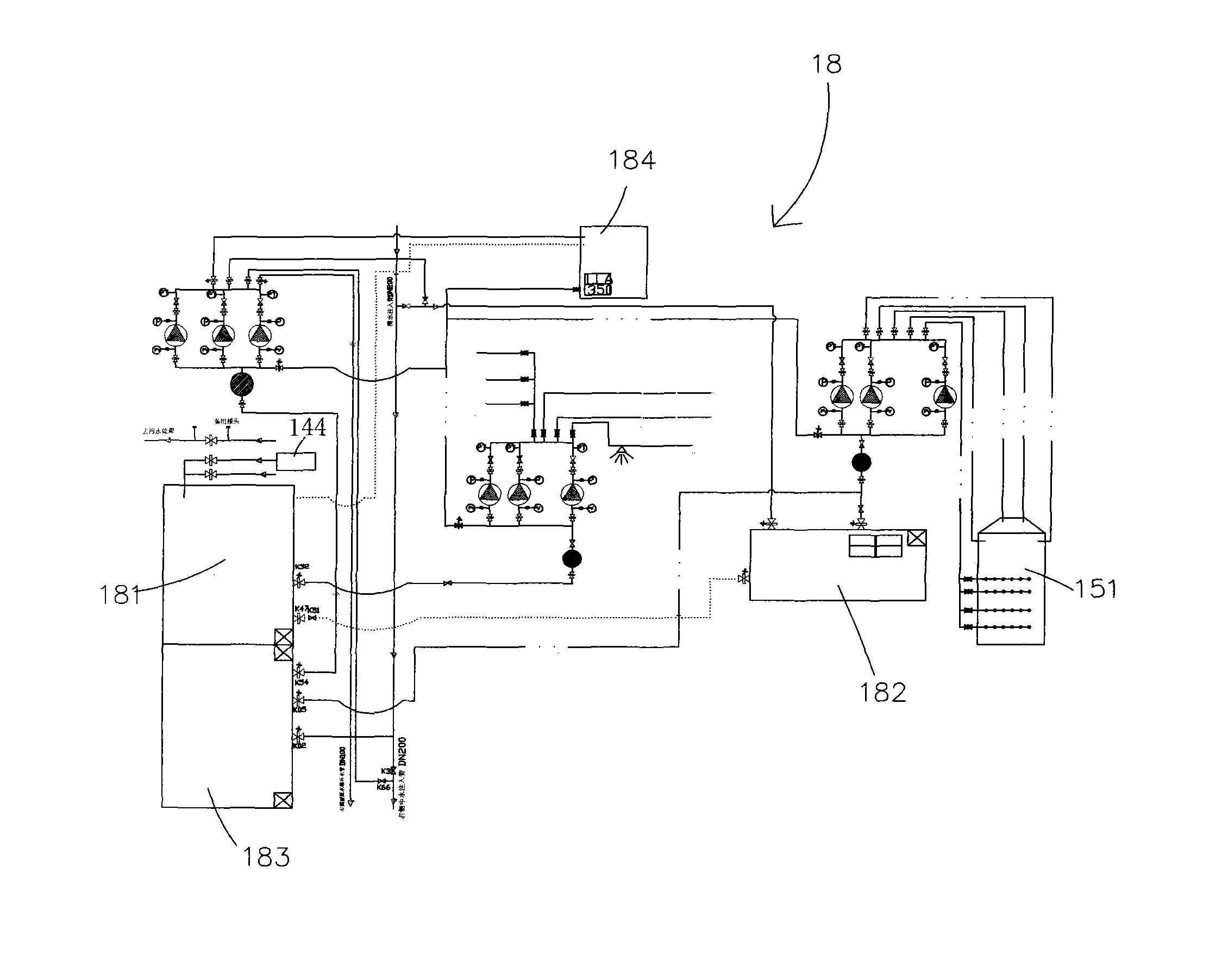

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] Figure 4 Be the flow chart of garbage water classification treatment method of the present invention, as Figure 4 Shown: a garbage water classification method of the present invention, comprising: Step 1, the garbage in the storage module is broken through the garbage feeding module and evenly transmitted to the follow-up processing module; Step 2, using screening and water washing to treat the garbage Small particles in the waste; step 3, use the heavy object separation module to feed the water pump to the separation box, let the heavy objects sink and separate naturally, and the light garbage suspended above the water layer overflows the heavy object separation box with the water flow. The deposited inorganic heavy objects are selected through the magnetic separation device to select the heavy metal objects; step 4, use the air sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com