Walking beam cooler and stepping control method thereof

A control method and step-by-step technology, which is applied in the direction of cooling bed, metal rolling, manufacturing tools, etc., can solve the problems of movable beam lifting lag, increase of steel plate cooling unevenness, steel plate warping and deformation, etc., and achieve the elimination of lifting lag , Improve cooling uniformity, and prevent warping and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

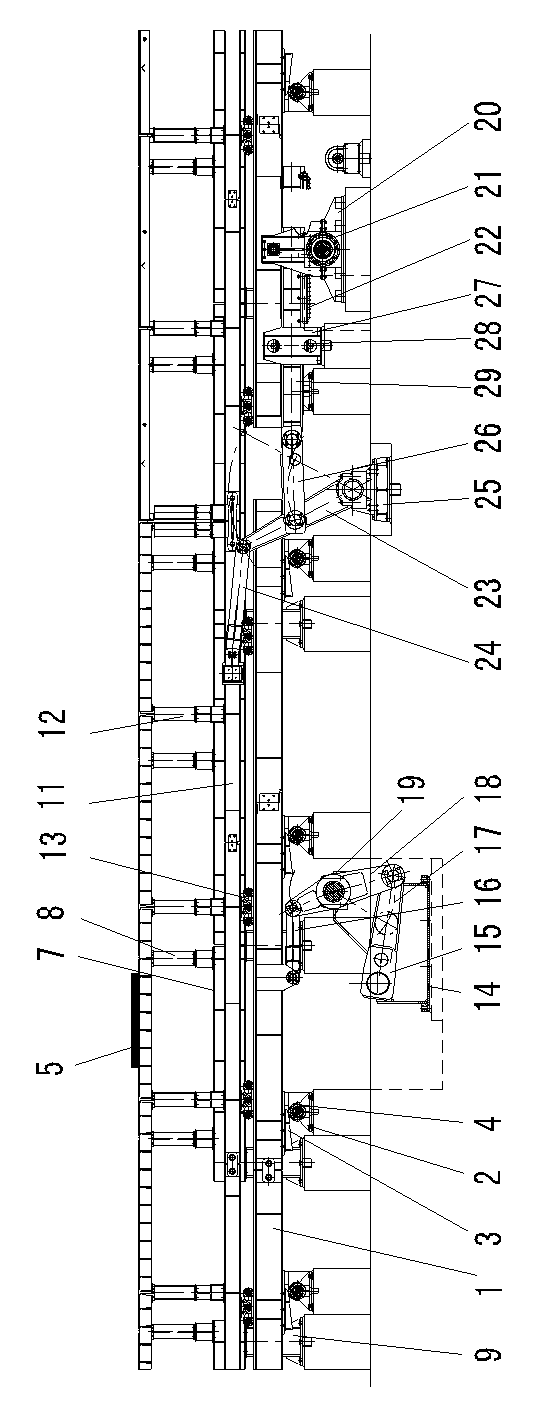

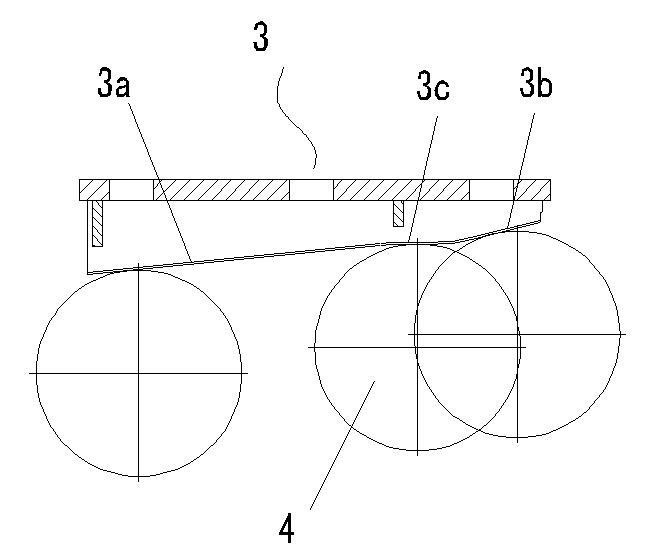

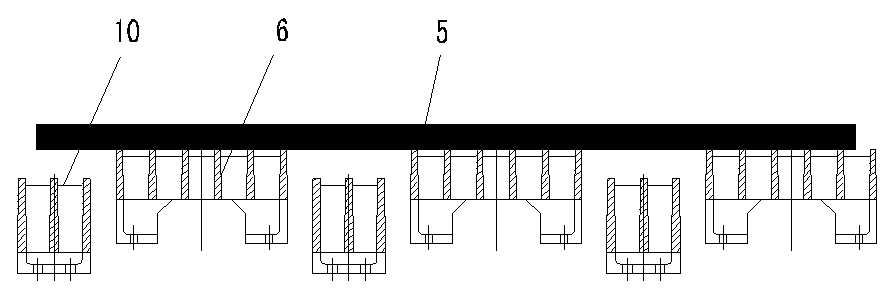

[0036] Such as figure 1 Shown is a schematic structural view of an embodiment of the walking cooling bed of the present invention. The walking cooling bed of this embodiment comprises a fixed beam, a movable beam, a traverse device and a lifting device. The wedge-shaped lifting lead curved surface that fits with the lifting seat 2, the wedge-shaped lifting lead curved surface includes a lifting slope 3a located at both ends of the lifting wedge block 3 with the same inclination direction, a lifting slope 3b and a slope between the two lifting slopes 3a, 3b. The median level 3c, the distance between the top surface of the movable beam and the median level 3c is equal to the distance from the top surface of the fixed beam to the matching point / surface between the lifting base 2 and the median level 3c. Preferably, the lifting se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com