Nano-fluid electrostatic atomization controllable jet micro-lubrication grinding system

A nano-fluid and electrostatic atomization technology, applied in grinding/polishing equipment, grinding/polishing safety devices, metal processing equipment, etc., to achieve low-carbon, clean, efficient micro-lubrication grinding, and reduce drift and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described below in conjunction with accompanying drawing.

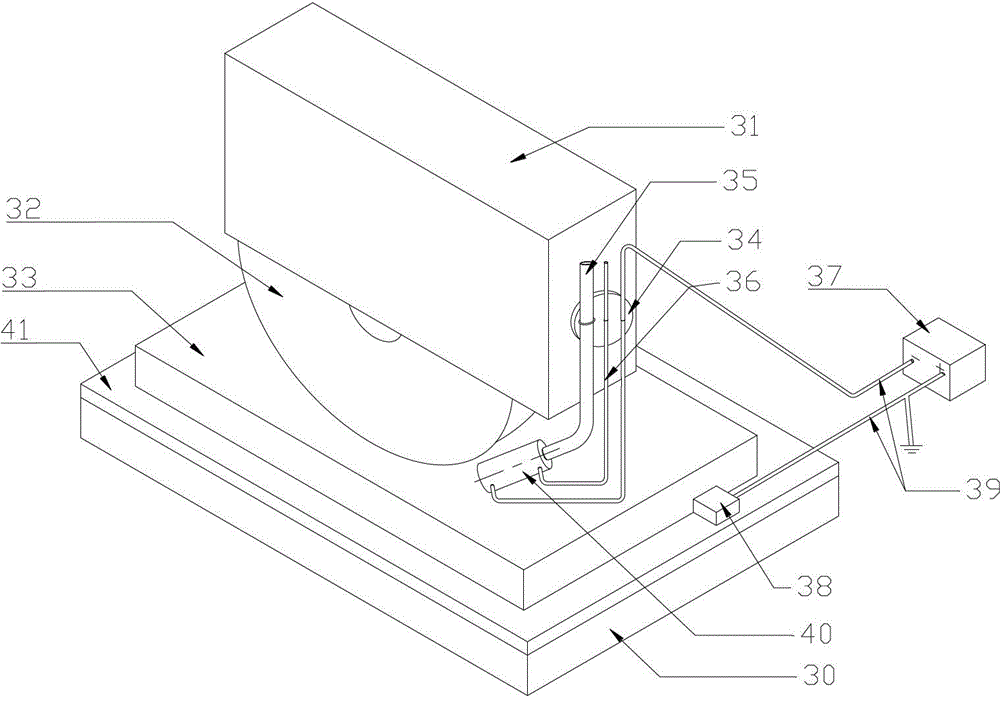

[0044] like figure 1 As shown, the workbench 30 of the grinding machine is covered with an insulating plate 41 (this new material can be magnetically conductive, but not conductive, so that it can not only ensure the installation of the workpiece but also ensure the formation of a stable electric field between the nozzle and the workpiece). The magnetic chuck 34 is adsorbed on the side of the grinding wheel cover 31 to fix the nanofluid conveying serpentine pipe 35 , the compressed gas conveying serpentine pipe 36 and the high-voltage electric wire 39 that is connected to the nozzle. One end of the nanofluid delivery serpentine tube 35 is connected to the nanofluid inlet 19 , and the other end is connected to the turbine flowmeter 9 . One end of the compressed gas conveying serpentine pipe 36 is connected with the compressed gas inlet 23 , and the other end is connected with the turbin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com