A Nanofluid Oil Film Water Droplet Electrostatic Controllable Jet Cutting Method and Device

A nanofluid and cutting device technology, applied in metal processing equipment, maintenance and safety accessories, metal processing machinery parts, etc., can solve the adverse effects of the working environment and human health, cannot meet high efficiency, low energy consumption, and needs to be further improved and other issues to achieve the effect of reducing drift and loss, reducing rebound and splash, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

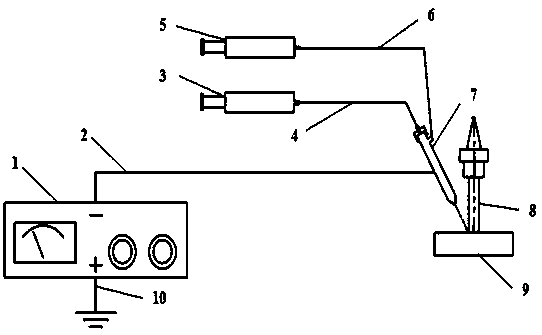

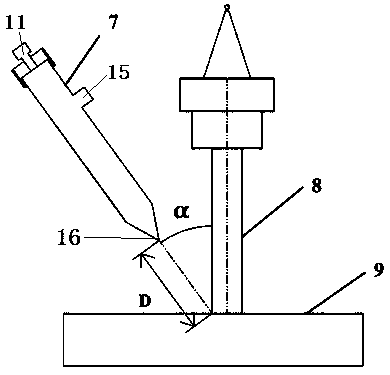

[0025] Such as figure 1 As shown, a nanofluid oil film water drop electrostatically controllable jet cutting device of the present invention includes an adjustable high-voltage electrostatic generator 1, a high-voltage cable 2, a first micro-injection pump 3, a first silicone rubber tube 4, and a second micro-injection pump 5 , the second silicone rubber tube 6, the coaxial nozzle 7, the tool 8, the workpiece 9 and the wire 10.

[0026] The adjustable high-voltage electrostatic generator 1 is connected with the coaxial nozzle 7 through the high-voltage cable 2, and provides DC negative high voltage to the coaxial nozzle 7. The positive output end of the adjustable high-voltage electrostatic generator 1 is grounded through the wire 10, the tool 8 and the workpiece 9 are indirectly grounded through the machine tool, the material of the tool 3 is hard alloy or high-speed steel, and the material of the workpiece 9 is metal.

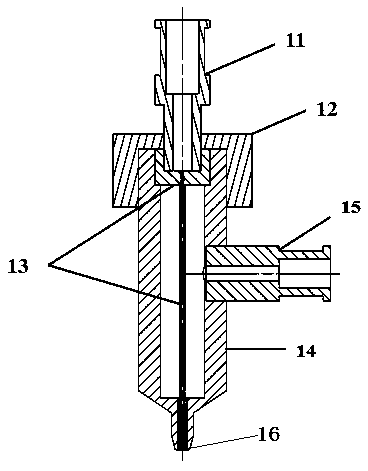

[0027]The coaxial nozzle 7 is connected to the first m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com