Producing method for simple SMT (surface mount technology) otter board

A manufacturing method and stencil technology, applied in printing, printing plate preparation, etc., can solve the problems of long stencil production cycle, large space occupied by stencil, and high manufacturing cost, so as to reduce management cost and maintenance cost, save materials, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

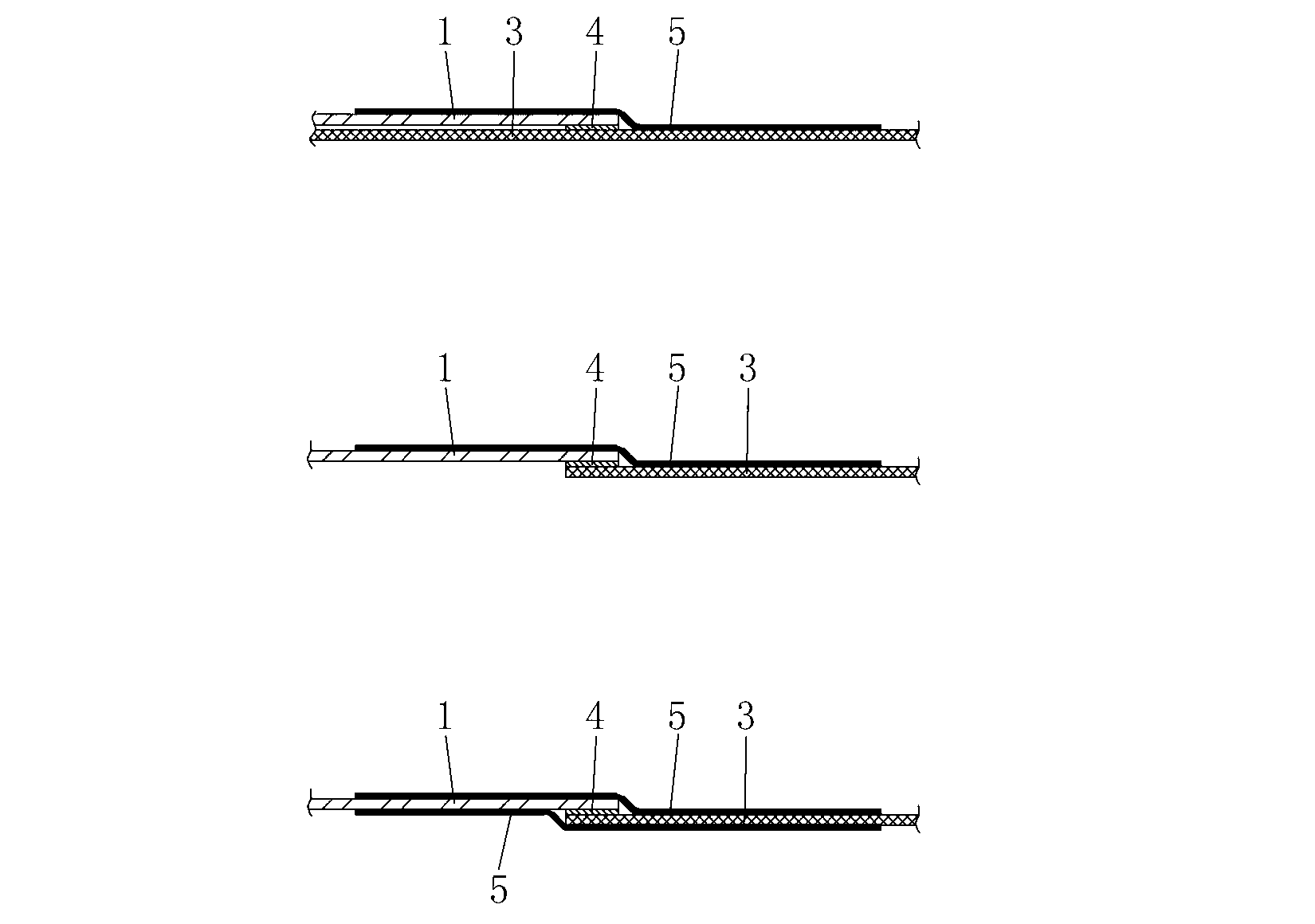

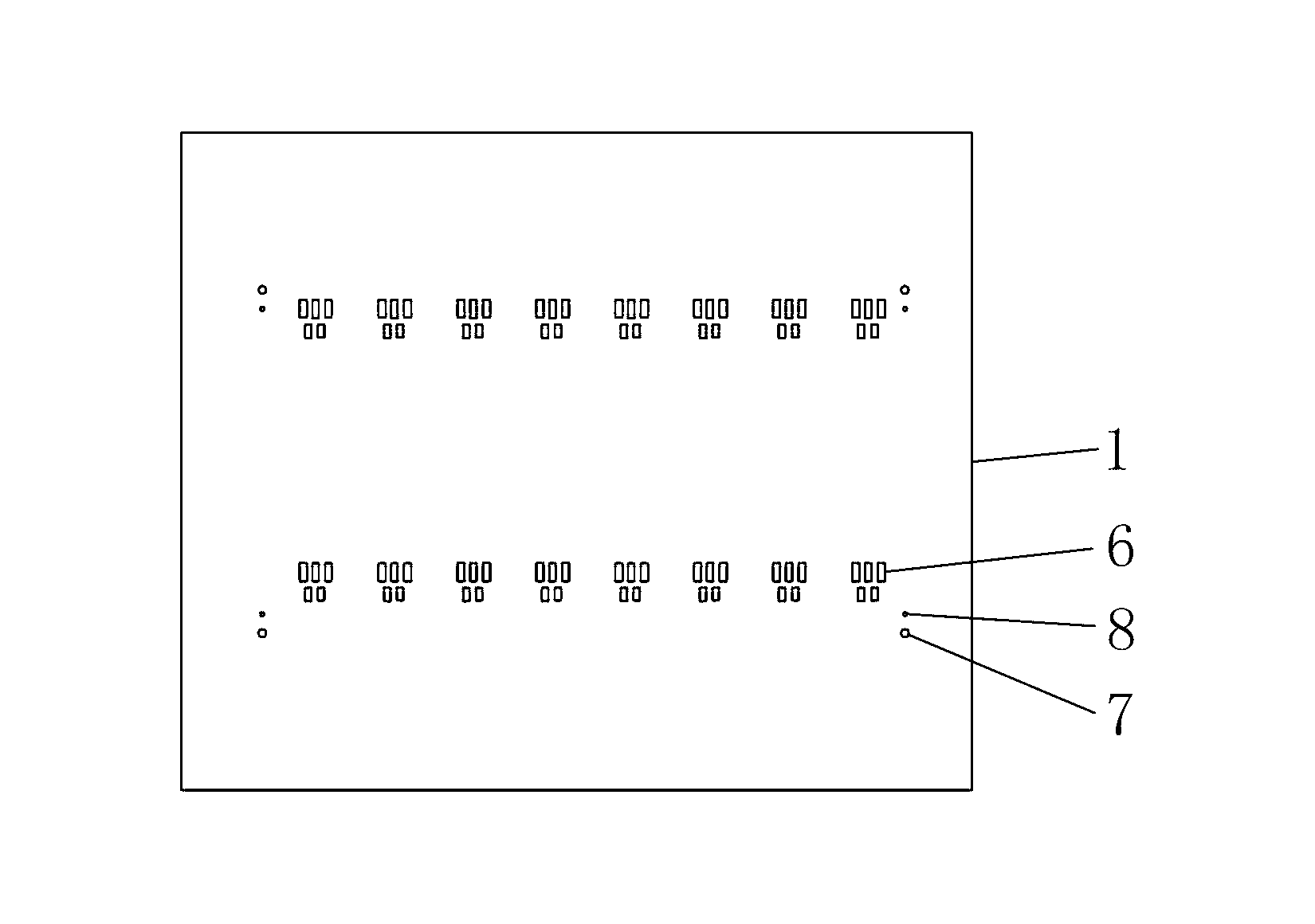

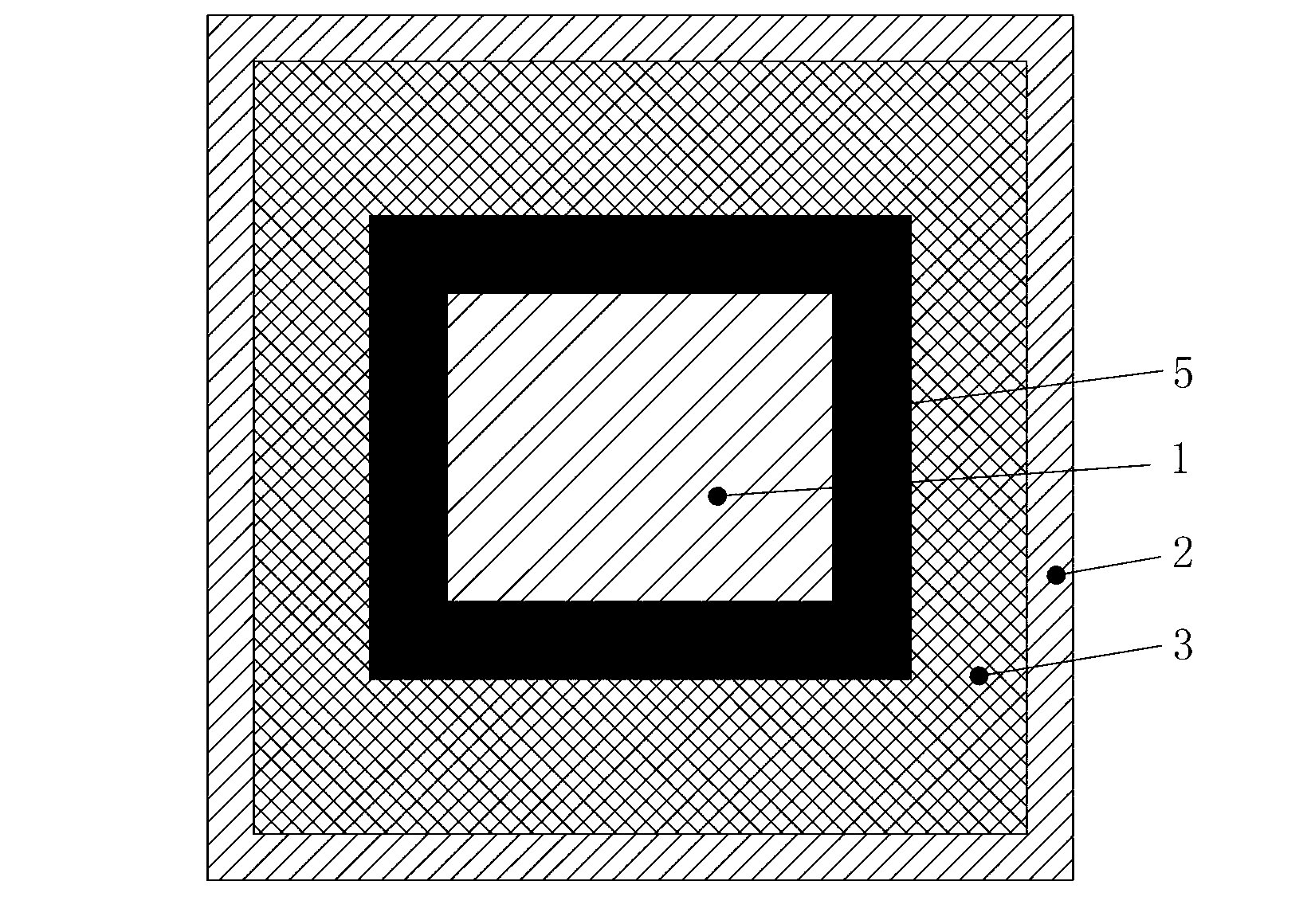

[0026] as attached figure 1 , attached figure 2 and attached image 3 As shown, the SMT simple stencil manufacturing method includes the following steps:

[0027] Step S1, cutting a plate made of FR4 material to replace the steel mesh, usually with a thickness of 0.1mm.

[0028] In step S2, the FR4 plate 1 is drilled with a laser machine according to the place where the FPC or PCB board is to be SMT, for adding tin.

[0029] Step S3, find a complete stencil with a tension of 15-25N / cm2 from the stencils scrapped after the printing process, the stencil is composed of a square frame 2 and a screen installed in the middle of the frame 2 3 composition.

[0030] Step S4, use the adhesive 4 to evenly paste the FR4 plate 1 to the center of the screen along the edge of the FR4 plate 1, and ensure that the surroundings of the FR4 plate 1 are parallel to the frame of the screen to avoid subsequent printing. , resulting in an angular shift.

[0031] Step S5, use transparent glue 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com